A kind of high strength-to-weight ratio C-shaped wooden structural material pressing mold and method

A technology of wood structure and pressing mold, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of high-space special-shaped structural materials, lack of strength-to-weight comparison, etc., and achieve the effect of improving comprehensive utilization, low cost, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with the accompanying drawings.

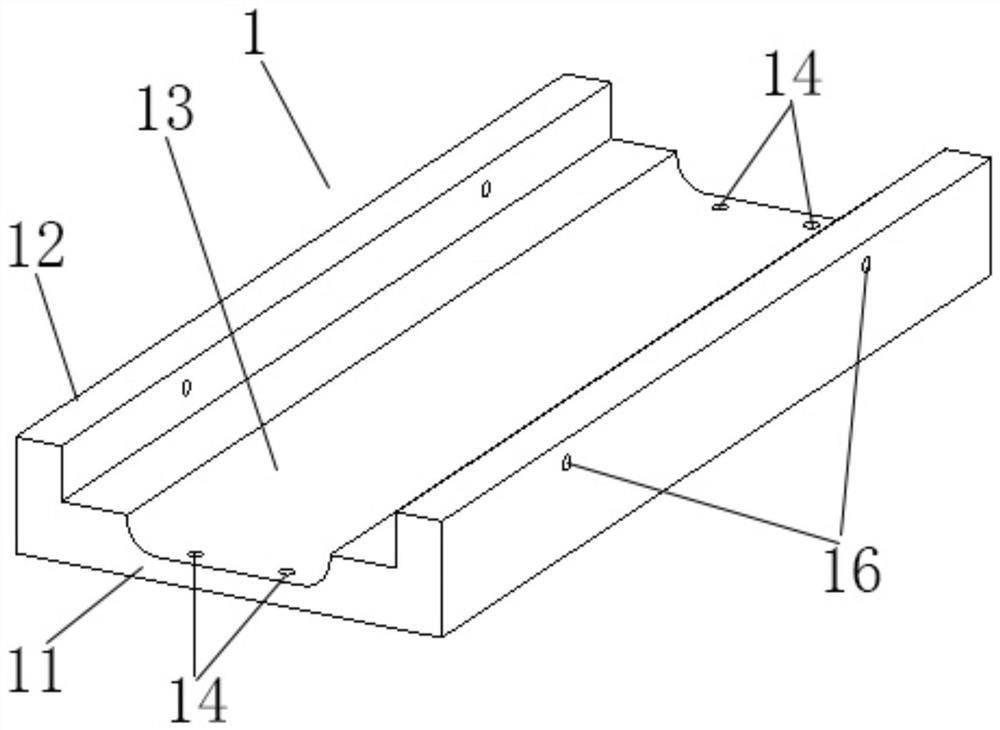

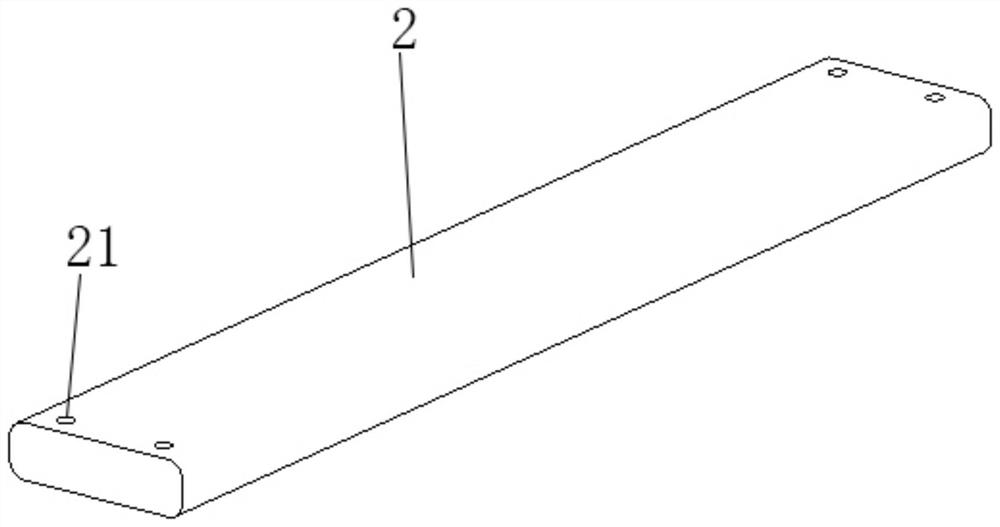

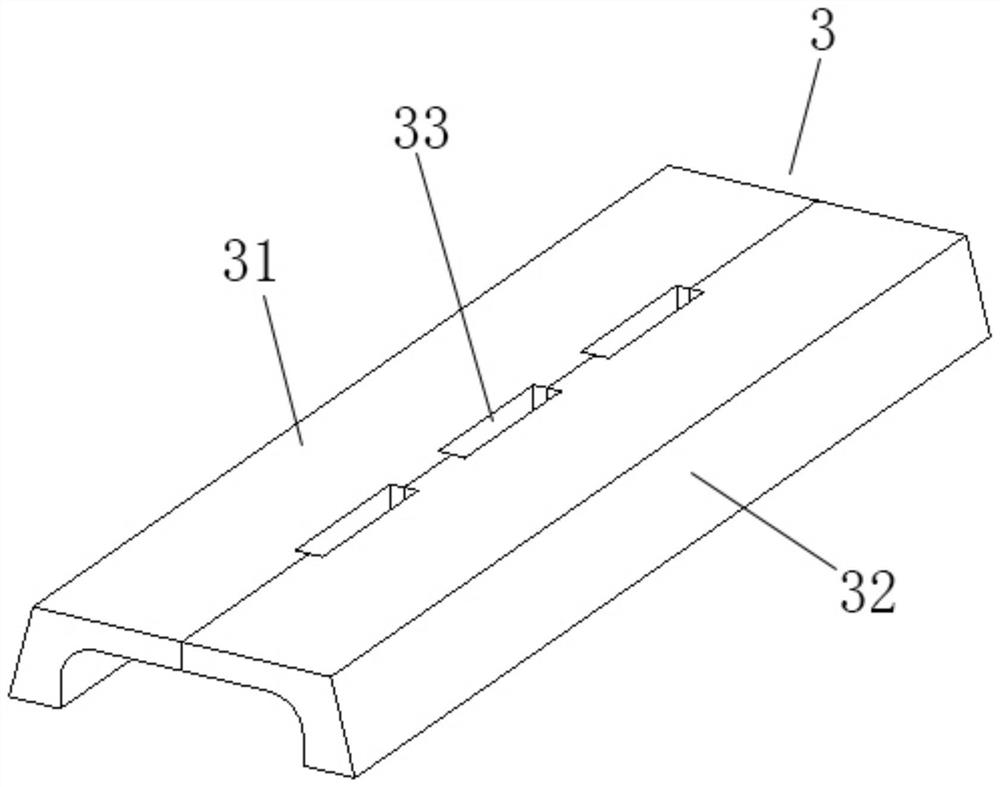

[0041] Such as Figure 1-10 , a high strength-to-weight ratio C-shaped wooden structural material pressing mold, including a base 1, a mandrel 2, a clamp 3, a pressure block 4, a wedge 5, and a pressure relief block 7, wherein:

[0042] Such as figure 1 , the base 1 is a U-shaped trough structure in cross section, which is composed of a bottom plate 11 and side walls 12 located on both sides of the bottom plate 11, and a groove 13 is opened in the bottom plate 11, and the groove 13 is used to place the mandrel 2 and C-shaped wooden structural material; the base 1 is processed from a whole piece of metal, the edge of the bottom plate 11 of the base 1 is provided with a first positioning hole 14, and the edge of the mandrel 2 is provided with a second positioning hole 21, through which the positioning pin 6 is sequentially Insert the first positioning hole 14 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com