Manufacturing method of density fiberboard for E0-level electronic circuit base plate

A technology of density fiberboard and electronic circuit, applied in the field of wood processing, can solve the problems of insufficient surface cleanliness, not heat-resistant, not flame-retardant, easily deformed by moisture, etc., so as to avoid the risk of burning, prevent deformation from moisture, and solve the problem of deformation from moisture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

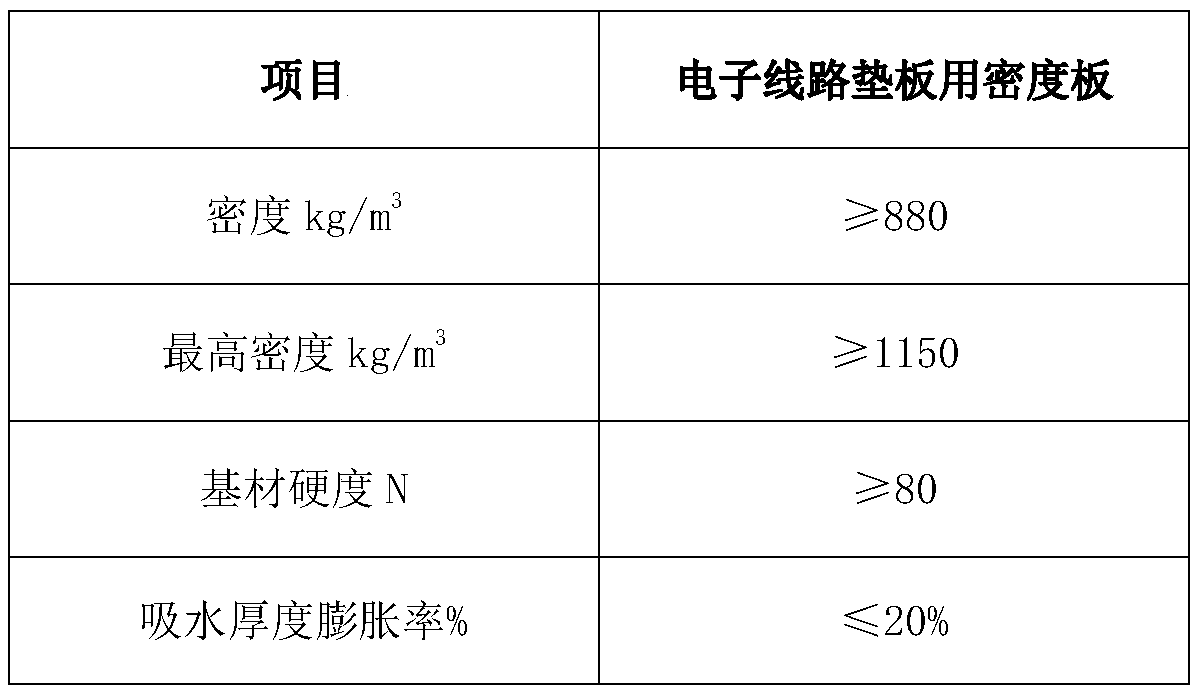

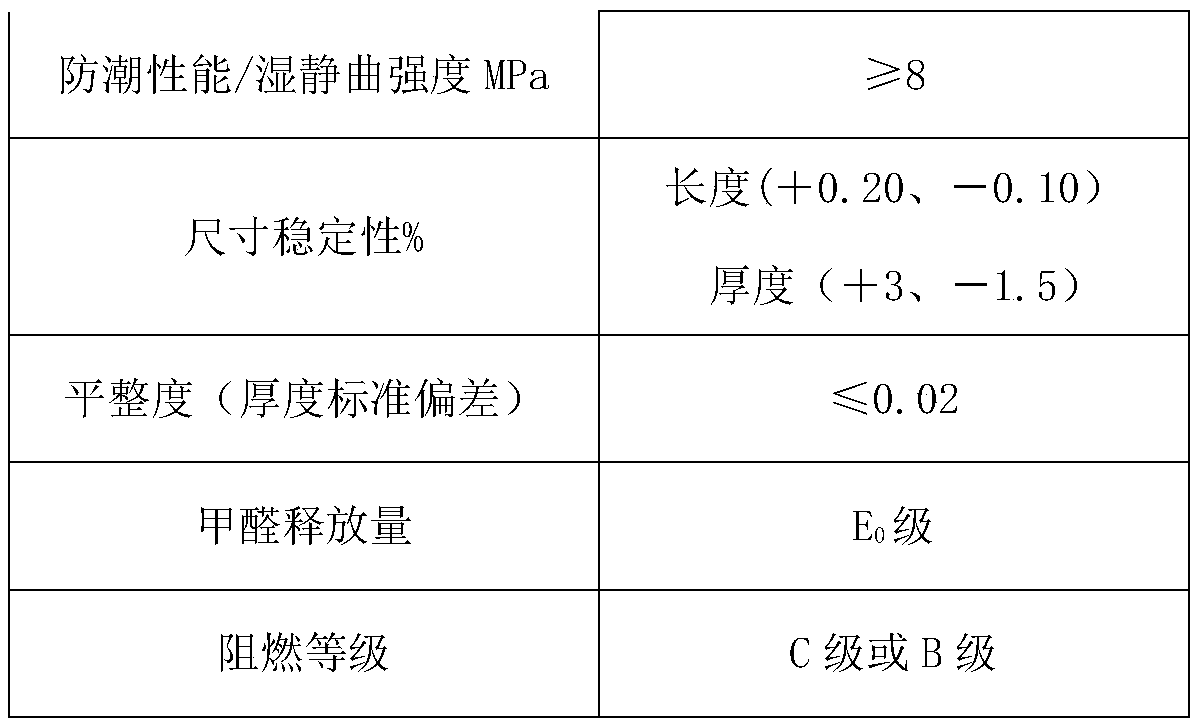

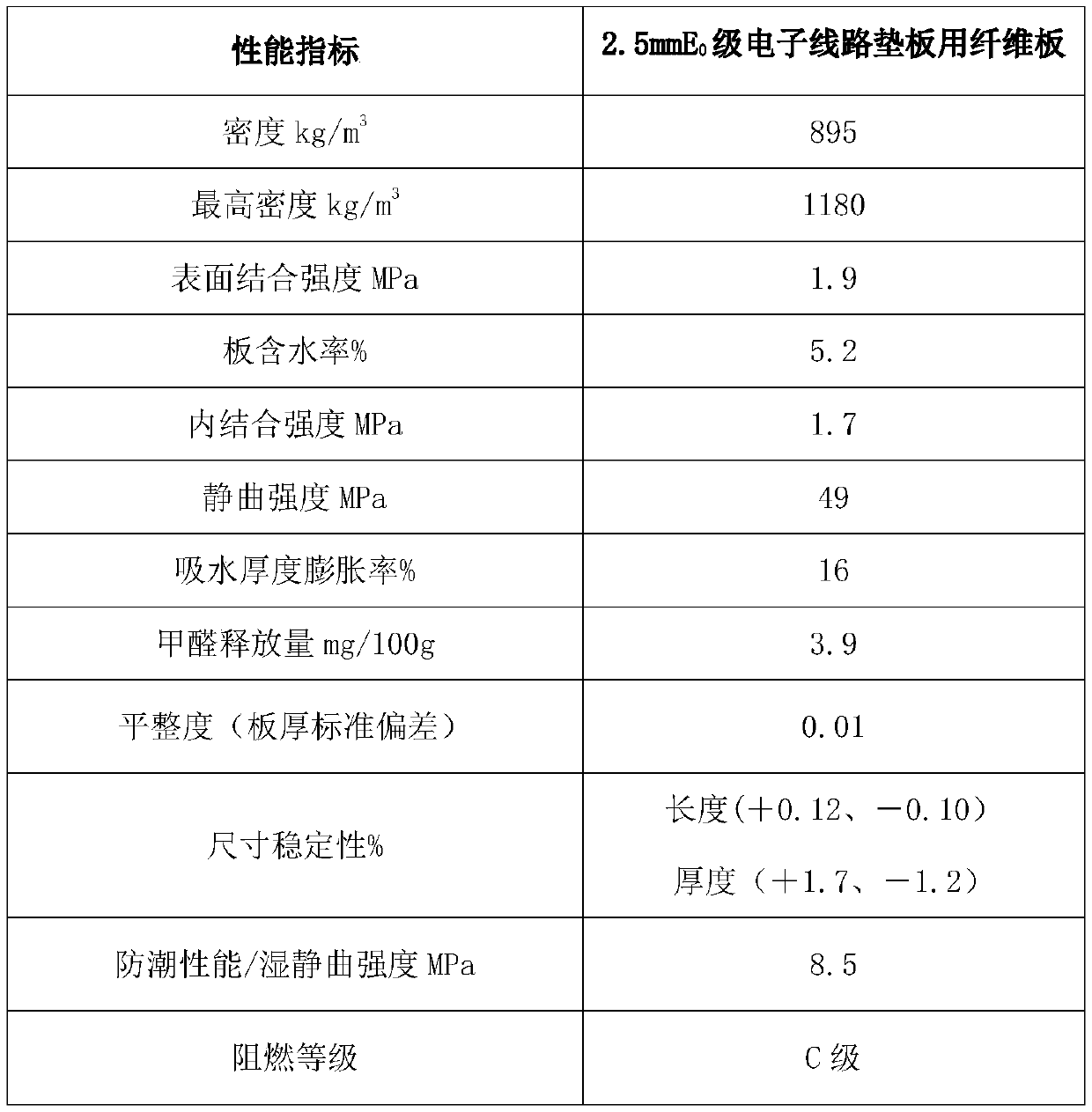

[0038] 2.5mm E 0 Manufacturing process of density fiberboard for grade electronic circuit backing board:

[0039] 1.E 0 Preparation of grade moisture-proof high-performance adhesive

[0040] The amount of melamine accounts for 10% of the weight of the whole liquid resin, and the total molar ratio of formaldehyde to urea and melamine is 0.82.

[0041] A, enter the first batch of formaldehyde (accounting for 85% of the total amount of formaldehyde), add sodium hydroxide solution (30%) to adjust the pH to 8.5-9.0;

[0042] B, drop into first batch of melamine (accounting for 50% of triamine total amount), be warming up to 88-90 ℃ gradually, react 30min;

[0043] C. Put in the first batch of urea, make the molar ratio of formaldehyde to urea and triamine at 1.94, react at 80-85°C for 20 minutes, add formic acid to adjust the pH to 6.7, and react until the viscosity is 15s;

[0044] D, add sodium hydroxide to adjust Ph=10, add the second batch of formaldehyde (accounting for 15% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com