Preparation method for water-glass modified amino resin

A technology of amino resin and water glass, applied in adhesive types, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve the problems of reduced water-resistant bonding strength of plates, environmental pollution, etc., and achieve simple manufacturing process, The effect of reducing manufacturing cost and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

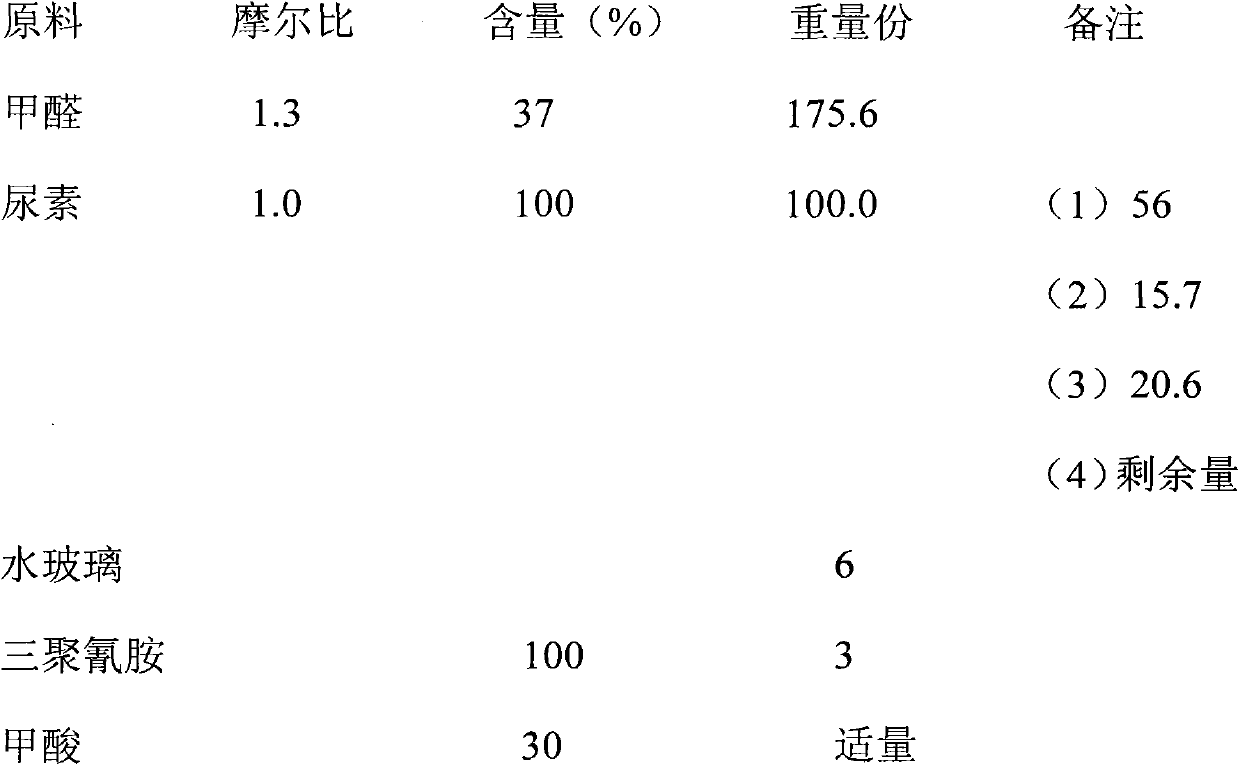

[0012] 1. Raw material formula

[0013]

[0014] 2. Synthesis process

[0015] Add formaldehyde into the reaction kettle according to the above raw material formula, slowly add water glass to react with formaldehyde under stirring, make the pH value of the solution 7~9, heat to 45°C, react for 15 minutes, add the first batch of urea, and raise the temperature steadily to 90± Incubate at 2°C for half an hour to complete hydroxymethylation. Add melamine, water glass, and the second batch of urea to maintain the pH value of 7.6-8.5, keep it at 90±2°C for 40 minutes, adjust the pH value to 4-6 with formic acid, and apply -4 cups of 22-25 to the viscosity of 25°C Seconds, add water glass to keep the pH value at 7~8, add the third batch of urea, keep it at 90±2°C for 30 minutes, cool down to 70±5°C, add the remaining urea, keep it warm for 30 minutes, then lower the temperature to 40°C to lower the pH value 7 to 8 discharges.

experiment example

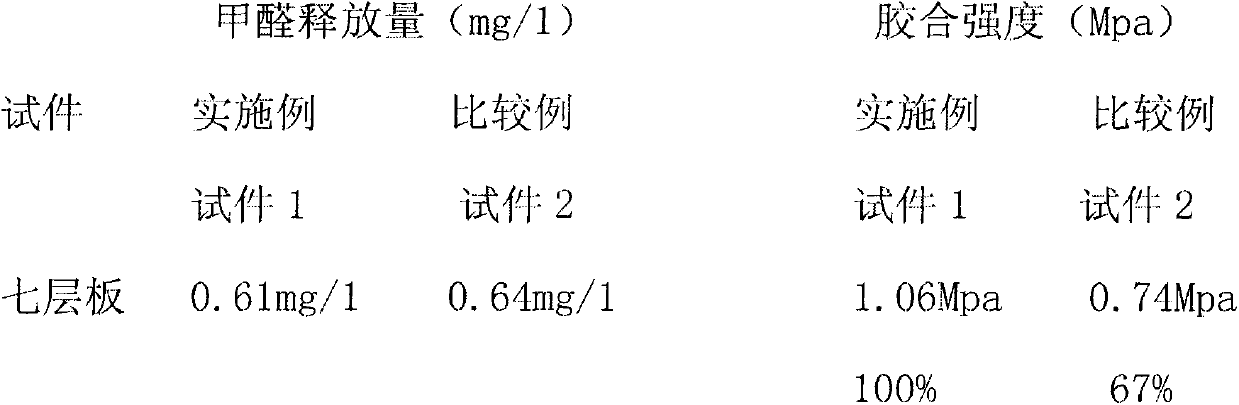

[0021] Adopt the common amino resin adhesive obtained by the water glass modified amino resin adhesive obtained by the embodiment of the present invention (molar ratio is 1: 1.1, solid content 54%) and comparative example (molar ratio is 1: 1.1, solid content 54%) Seven-ply plywood specimen 1 and specimen 2 were produced. Add 20-25% flour, 0.5% ammonium chloride and additive B (prepared by yourself) by resin weight when coating the glue.

[0022] The veneer is 1.7mm poplar wood Hot pressing process: pressure 1.0~1.5Mpa

[0023] Temperature: 115±5℃ Time: 60~90s / mm

[0024] Measure the formaldehyde emission of test pieces 1 and 2 by desiccator method, and measure the bonding strength and formaldehyde emission of test pieces 1 and 2 according to the provisions of GB / T17657-1999 "Test Methods for Physical and Chemical Properties of Wood-based Panels and Decorative Wood-based Panels". and bonding strength are shown in Table 1

[0025] Table 1

[0026]

[0027] As can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com