Seepage-preventing wood veneer structure for wall and installing method thereof

A wood veneer and anti-leakage technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of difficulty in replacing or adjusting wood veneer panels, affecting decorative effects, and cumbersome construction steps, so as to avoid moisture deformation , Improve moisture-proof effect, reduce maintenance time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0025] Example.

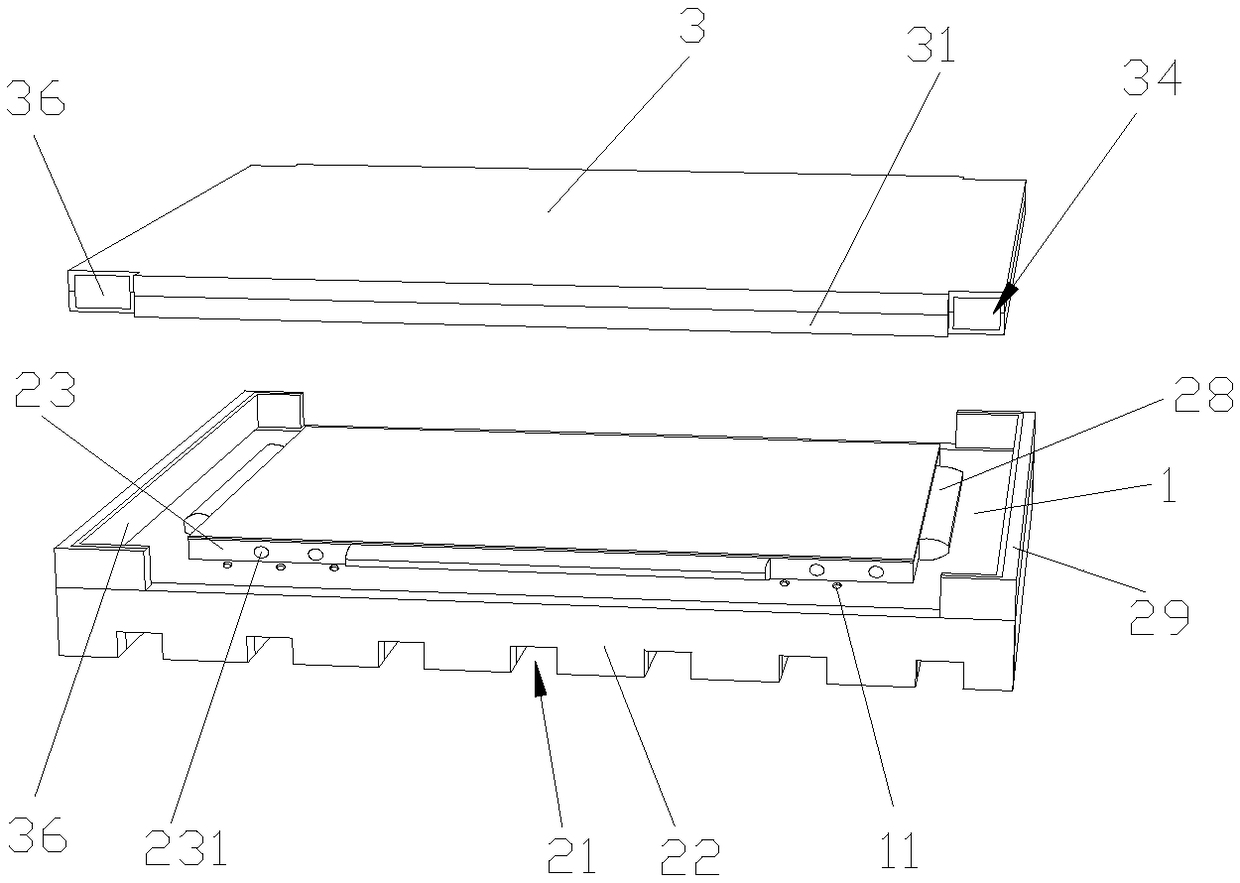

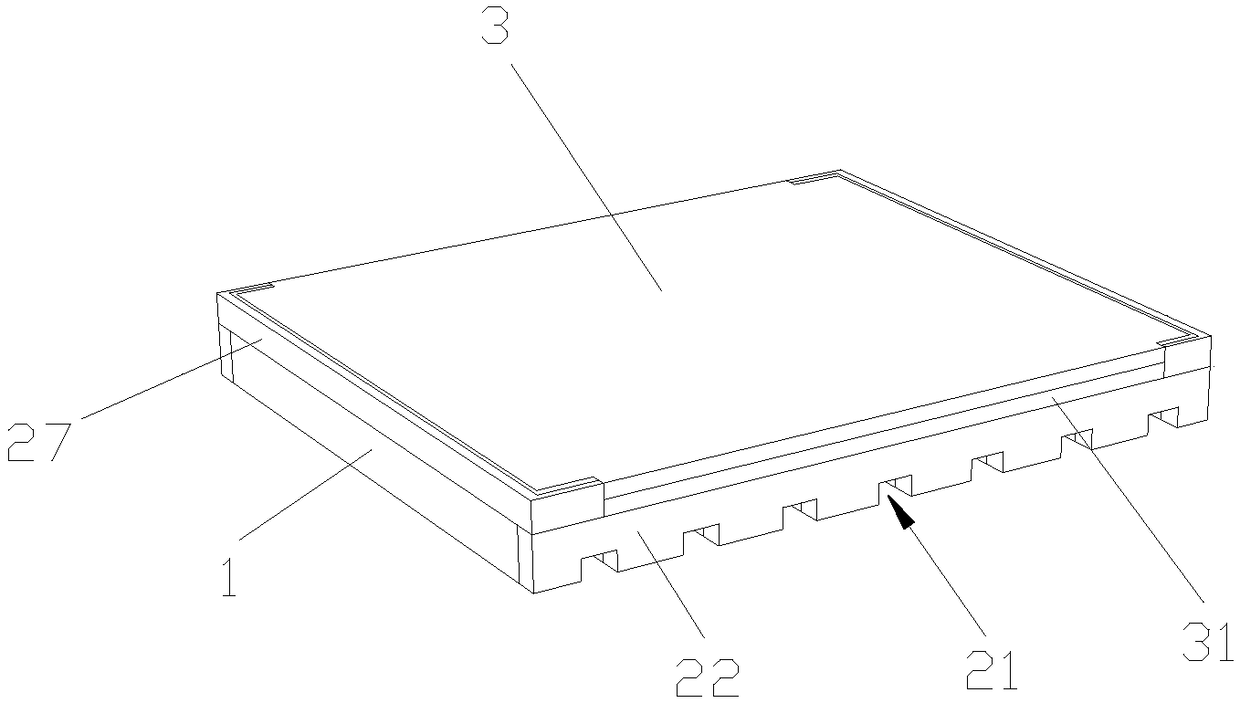

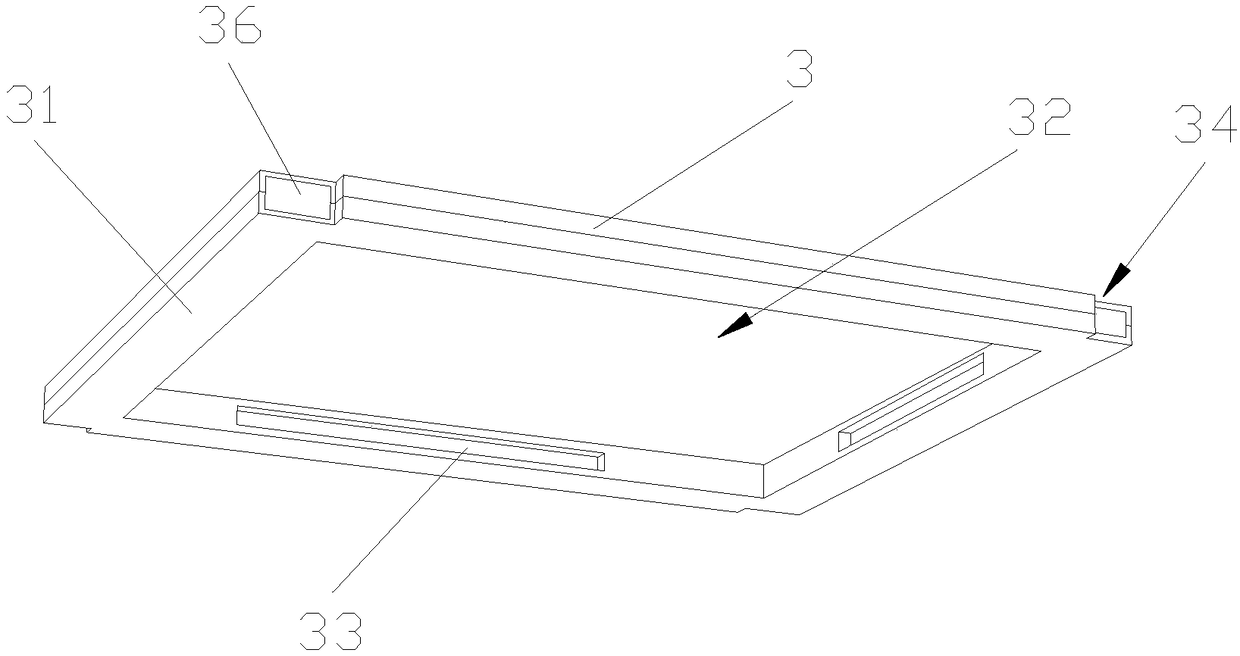

[0026] Such as Figure 1-5 As shown, an anti-leakage wood veneer structure for a wall includes a base plate 1, the bottom surface of the base plate 1 is provided with a longitudinally distributed diversion groove 21, and the end surface of the base plate 1 is located at both ends of the diversion groove 21. Layer 22, the top surface of the substrate 1 is provided with a fixed plate 23, the end surface of the fixed plate 23 is provided with a chute 26, the chute 26 is connected with a block 28 through a spring 27, the top surface and the bottom surface of the block 28 are arc The surface of the fixed plate 23 is provided with an isolation film 24, the surface of the isolation film 24 is provided with a sound-absorbing layer 25, the substrate 1 is connected to the panel 3 through the fixed plate 23; the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com