Waterproof protective material for deep well and preparation method of waterproof protective material

A protective material, deep well technology, applied in the direction of coating, can solve the problems of cracking or even collapse, weak adhesion, material aging, etc., to achieve the effect of improving anti-oxidation performance, improving surface viscosity, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

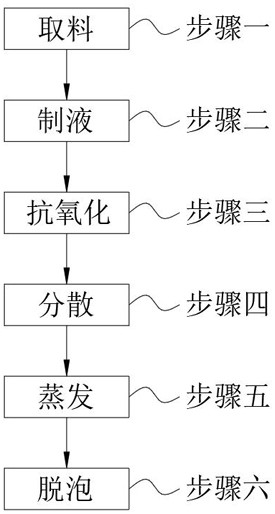

Method used

Image

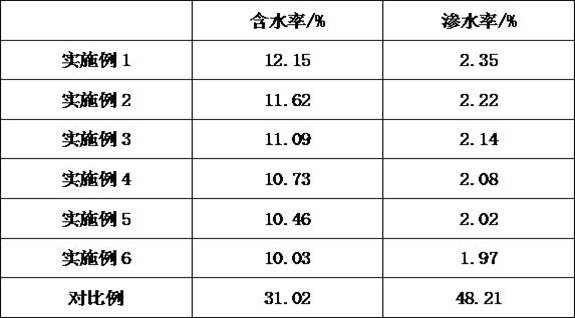

Examples

Embodiment 1

[0025] A waterproof protective material for deep wells, the formula includes: water-based polymethyl silicone resin, deionized water, butyl stearate, antioxidant, hydrophobic agent, carboxymethyl cellulose, polyacrylamide, fatty acid glyceride and coloring The parts by weight of each component are: 78 parts of water-based polymethyl silicone resin, 15 parts of deionized water, 3 parts of butyl stearate, 2 parts of antioxidant, 2 parts of hydrophobic agent , 1 part of carboxymethyl cellulose, 2 parts of polyacrylamide, 1 part of fatty acid glycerides and 1 part of colorant, wherein the antioxidant is composed of tert-butyl hydroquinone, phenylenediamine and thiodicarbonate Propionate is mixed, and the weight ratio of tert-butyl hydroquinone, phenylenediamine and thiodipropionate is 3:1:1, and the hydrophobic agent is composed of dimethicone, calcium palmitate and microcrystalline Paraffin is mixed, and the weight ratio of dimethyl silicone oil, calcium palmitate and microcrysta...

Embodiment 2

[0034] A waterproof protective material for deep wells, the formula includes: water-based polymethyl silicone resin, deionized water, butyl stearate, antioxidant, hydrophobic agent, carboxymethyl cellulose, polyacrylamide, fatty acid glyceride and coloring The parts by weight of each component are: 79 parts of water-based polymethyl silicone resin, 16 parts of deionized water, 3 parts of butyl stearate, 3 parts of antioxidant, 2 parts of hydrophobic agent , 1 part of carboxymethyl cellulose, 2 parts of polyacrylamide, 1 part of fatty acid glycerides and 1 part of colorant, wherein the antioxidant is composed of tert-butyl hydroquinone, phenylenediamine and thiodicarbonate Propionate is mixed, and the weight ratio of tert-butyl hydroquinone, phenylenediamine and thiodipropionate is 3:1:1, and the hydrophobic agent is composed of dimethicone, calcium palmitate and microcrystalline Paraffin is mixed, and the weight ratio of dimethyl silicone oil, calcium palmitate and microcrysta...

Embodiment 3

[0043] A waterproof protective material for deep wells, the formula includes: water-based polymethyl silicone resin, deionized water, butyl stearate, antioxidant, hydrophobic agent, carboxymethyl cellulose, polyacrylamide, fatty acid glyceride and coloring The parts by weight of each component are: 81 parts of water-based polymethyl silicone resin, 17 parts of deionized water, 4 parts of butyl stearate, 3 parts of antioxidant, 3 parts of hydrophobic agent , 2 parts of carboxymethyl cellulose, 3 parts of polyacrylamide, 2 parts of fatty acid glycerides and 2 parts of colorants, wherein the antioxidant is composed of tert-butyl hydroquinone, phenylenediamine and thiodicarbonate Propionate is mixed, and the weight ratio of tert-butyl hydroquinone, phenylenediamine and thiodipropionate is 3:1:1, and the hydrophobic agent is composed of dimethicone, calcium palmitate and microcrystalline Paraffin is mixed, and the weight ratio of dimethyl silicone oil, calcium palmitate and microcr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com