Manufacture process for peeling broad beans

A production process, broad bean technology, applied in the peeling of vegetables or fruits, food preservation, egg preservation, etc., can solve the problems of bean kernel deformation, drying, poor air-drying cooling effect, long drying time, etc., and achieve uniform air-drying , shorten the drying time, the effect of short soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0032] For electric heating to generate steam or boiler heating to generate steam, it is a reasonable implementation of the technical solution of the utility model. Whether the hot gas is generated by the boiler or the electric heating is an effective embodiment of the present invention.

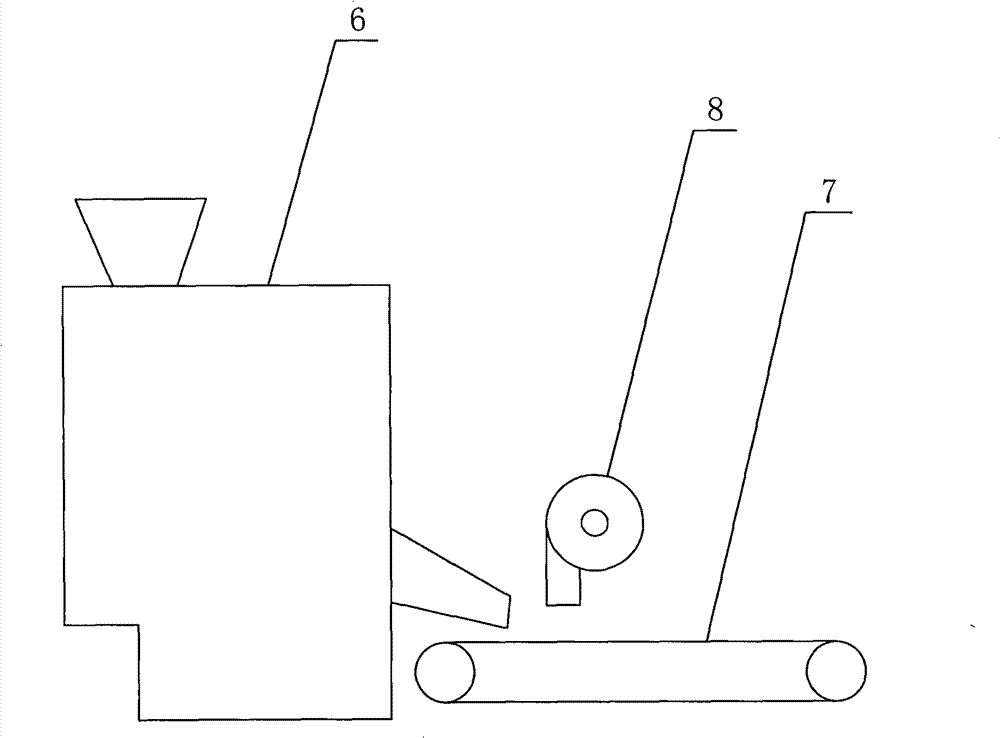

[0033] Such as Figure 1-Figure 7 As shown, the manufacturing process of the present invention mainly includes several steps:

[0034] Soaking of raw materials, peeling and dehydration, hot and cold air drying, and cooling of finished products.

[0035] In order to realize the manufacturing process of the present invention, corresponding improvements have been made to the processing equipment.

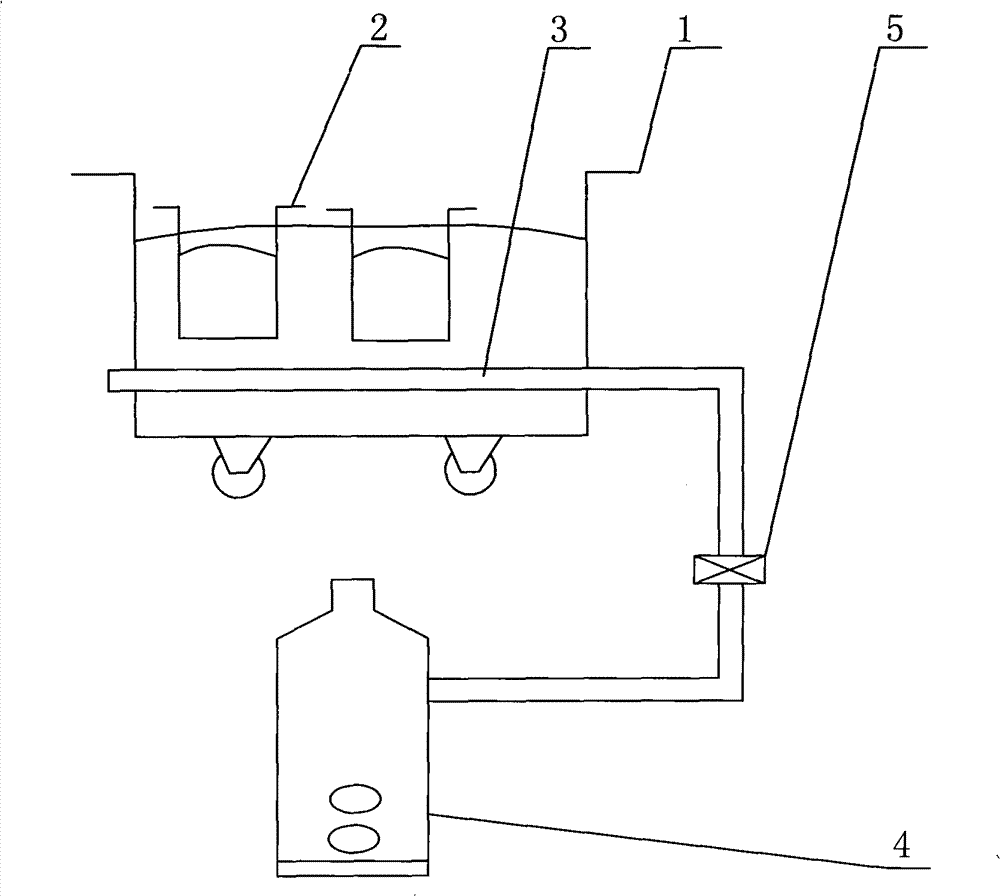

[0036] exist figure 1 Among them, in the raw material soaking process, a soaking water tank 1 is provided, and a steam heating pipe 3 with holes is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com