Fuel evaporation configuration structure of straddle type motorized cart

A technology of motorized two-wheeled vehicle and configuration structure, which is applied to the panniers, gasoline drums, bicycle accessories and other directions of bicycles, can solve the problems of complex confusion, the impact of the compactness of the locomotive, and the narrow space, so as to achieve a reasonable and concise layout and improve riding performance. Ride comfort and compact body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. In the following descriptions of the preferred embodiments of the present invention, unless otherwise stated, the descriptions in the directions of front, rear, left, right, and up and down all refer to the forward direction of the locomotive.

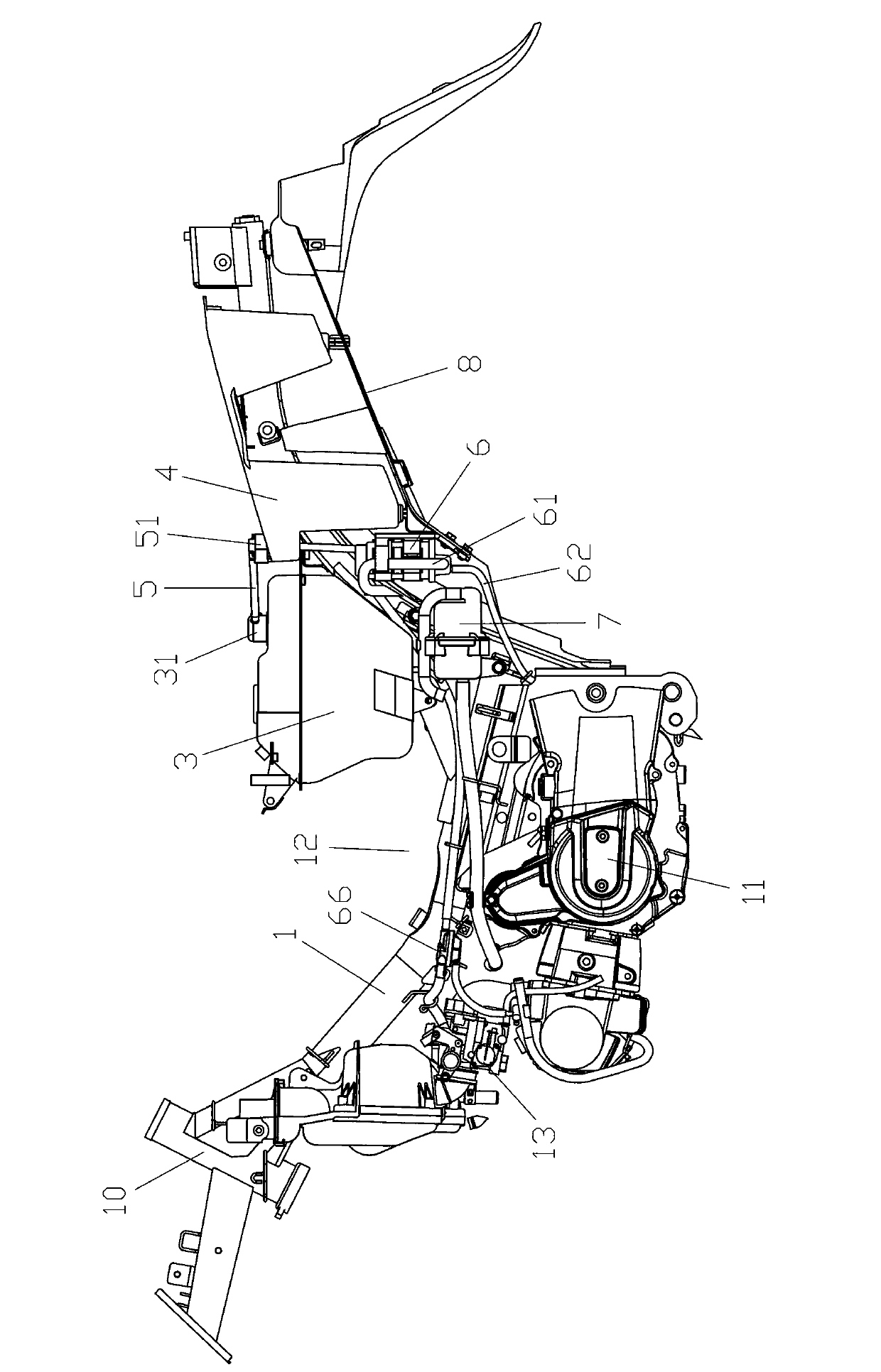

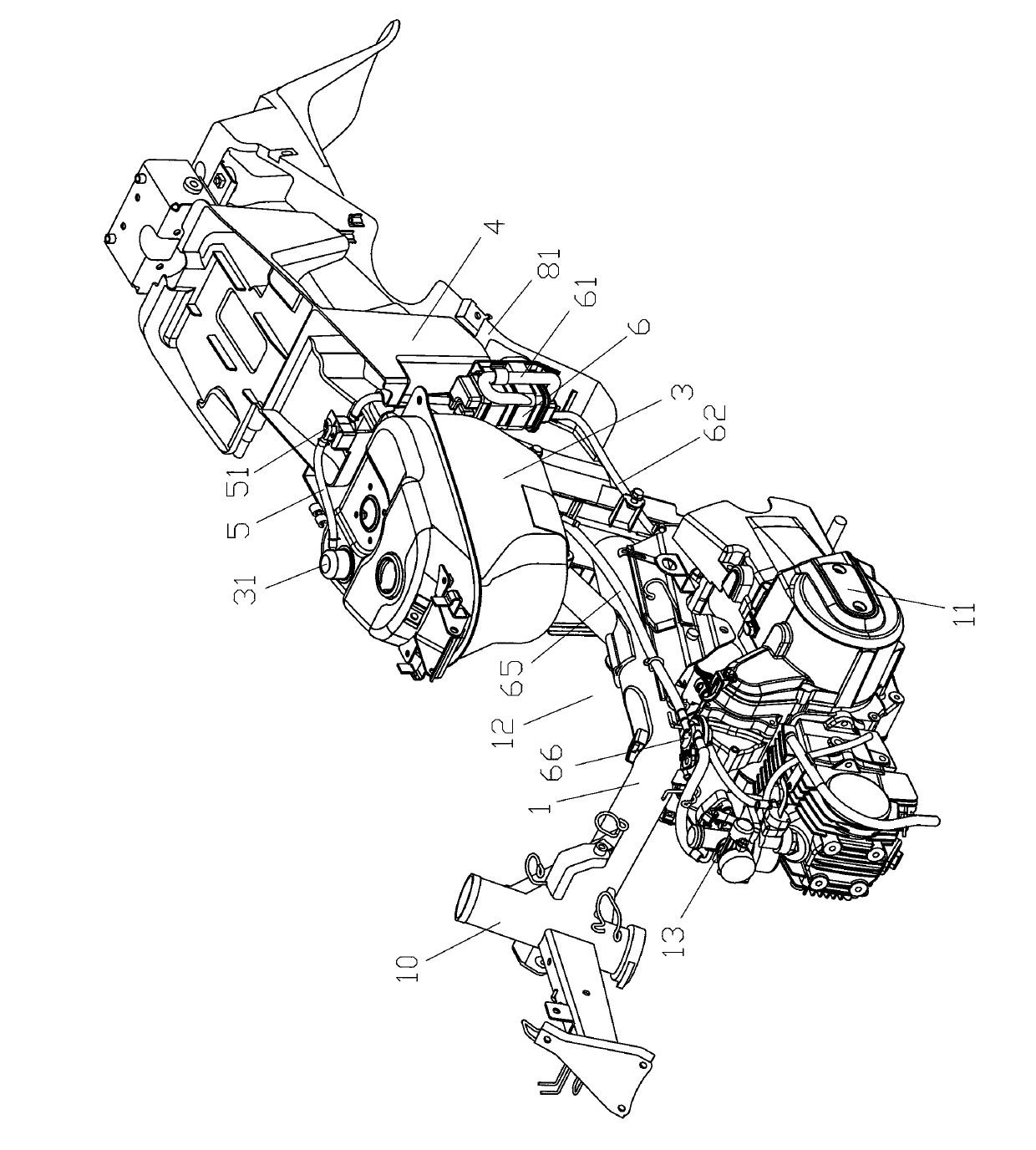

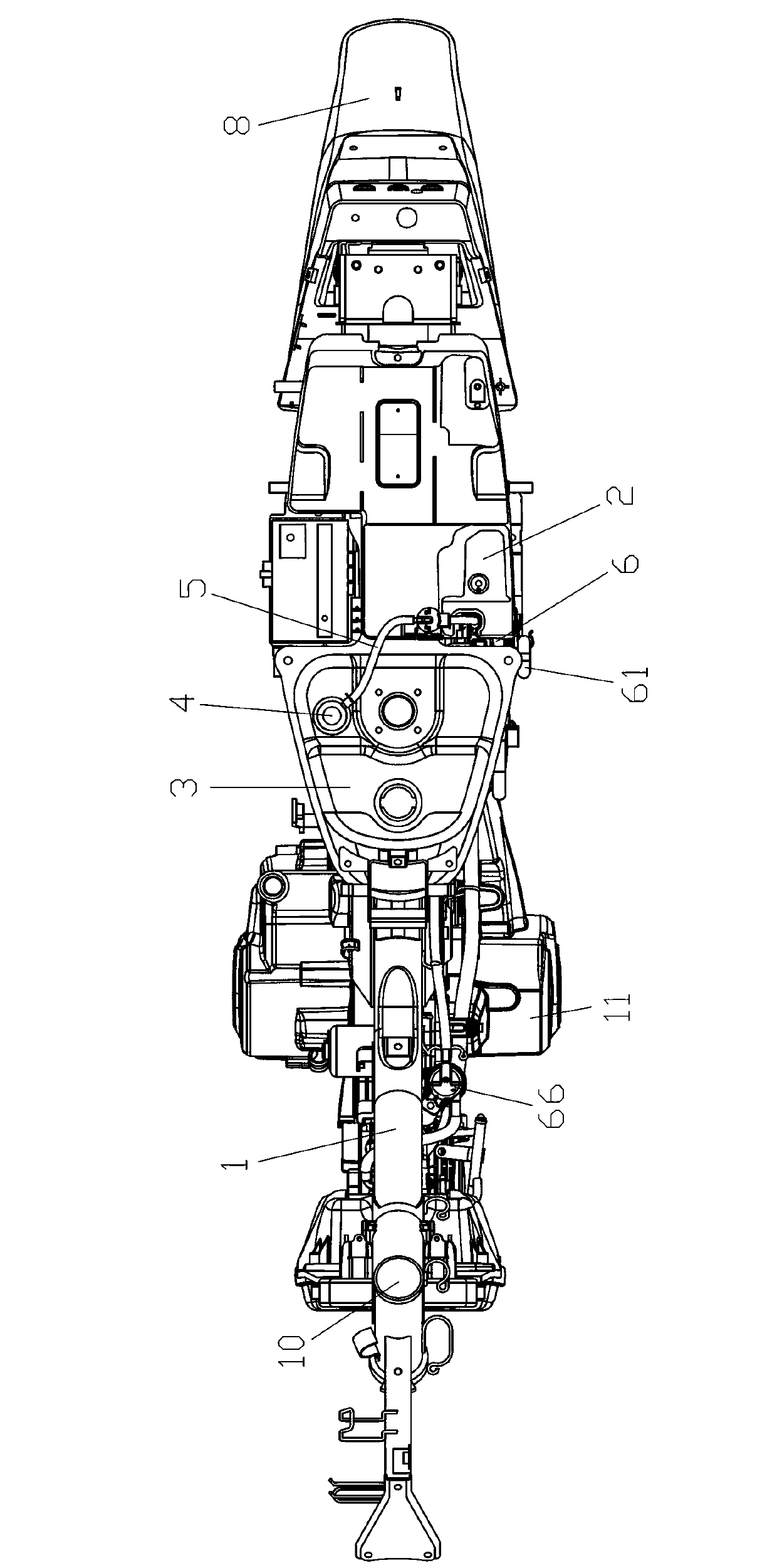

[0022] refer to Figure 1~Figure 5 , the fuel evaporation configuration structure of the straddle-type motorcycle of the present invention comprises a head pipe 10, which is connected with a main frame 1 extending backward and downward for suspending the engine 11 on the head pipe 10, the main frame The rear end of 1 is connected with a rear frame 2 extending rearward and upward, and a concave straddle 12 is formed between the main frame 1 and the rear frame 2, which is convenient for the rider to step over the vehicle body with one foot. A fuel tank 3 at least partially overlapped with the straddle por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com