Auxiliary frame structure

A sub-frame and body technology, applied in the field of sub-frame structure, can solve the problems of high cost, failure to ensure the installation stability of sub-frame and suspension system, bolt slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

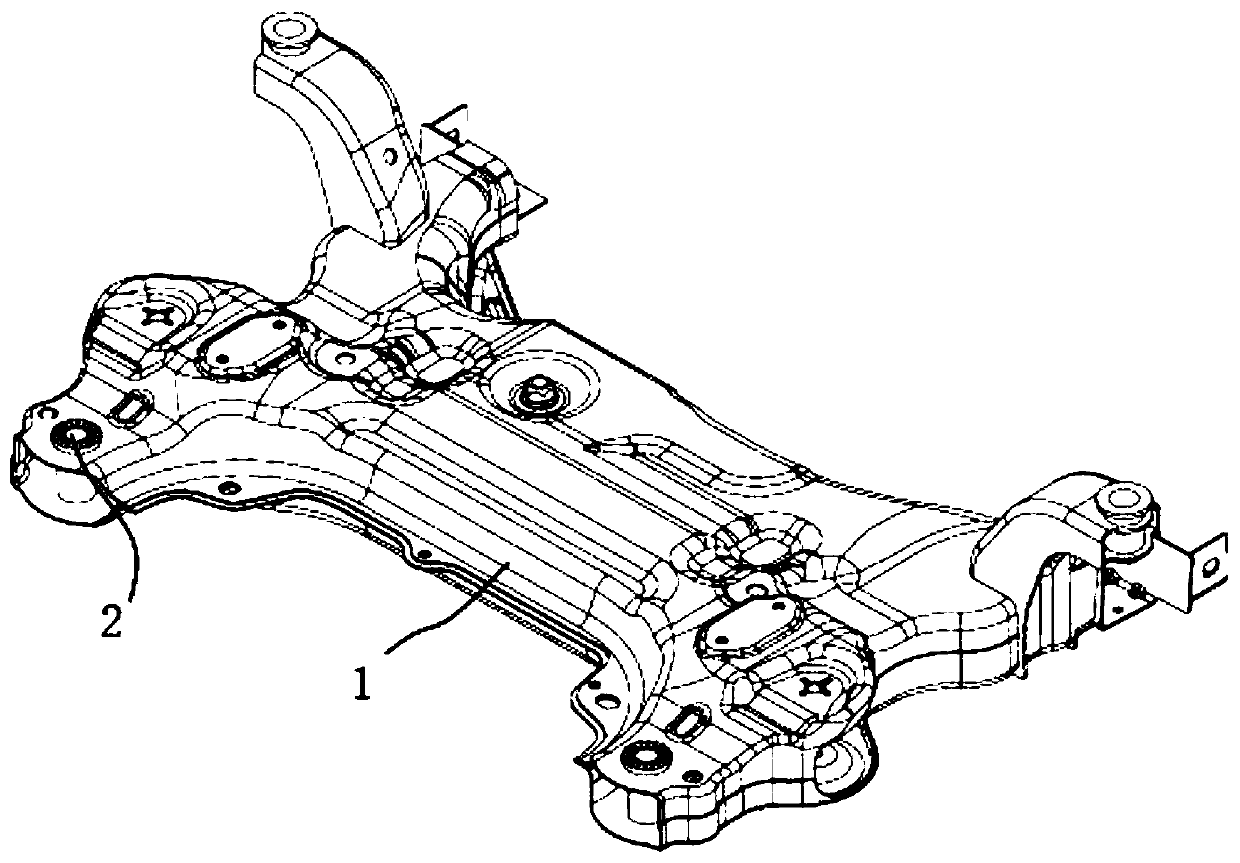

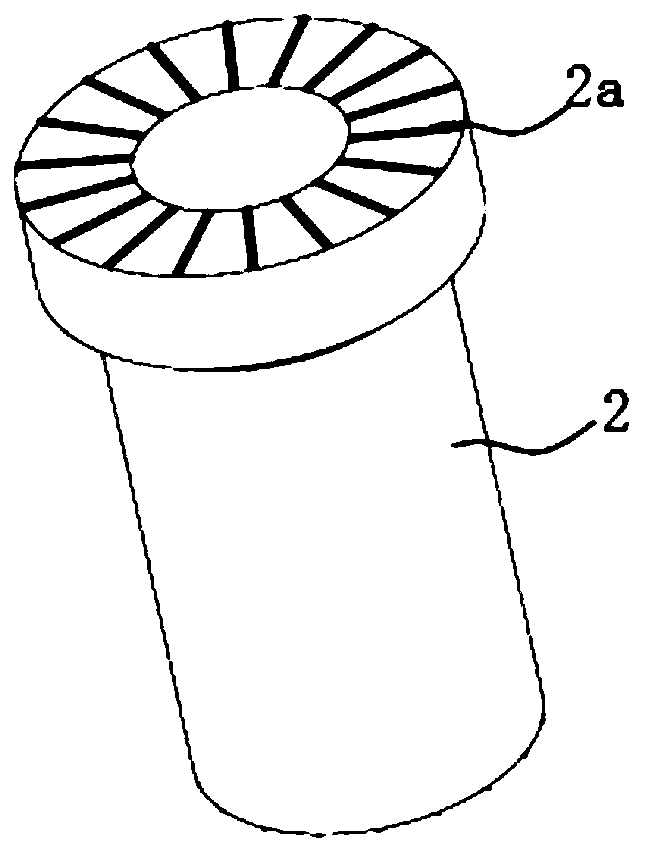

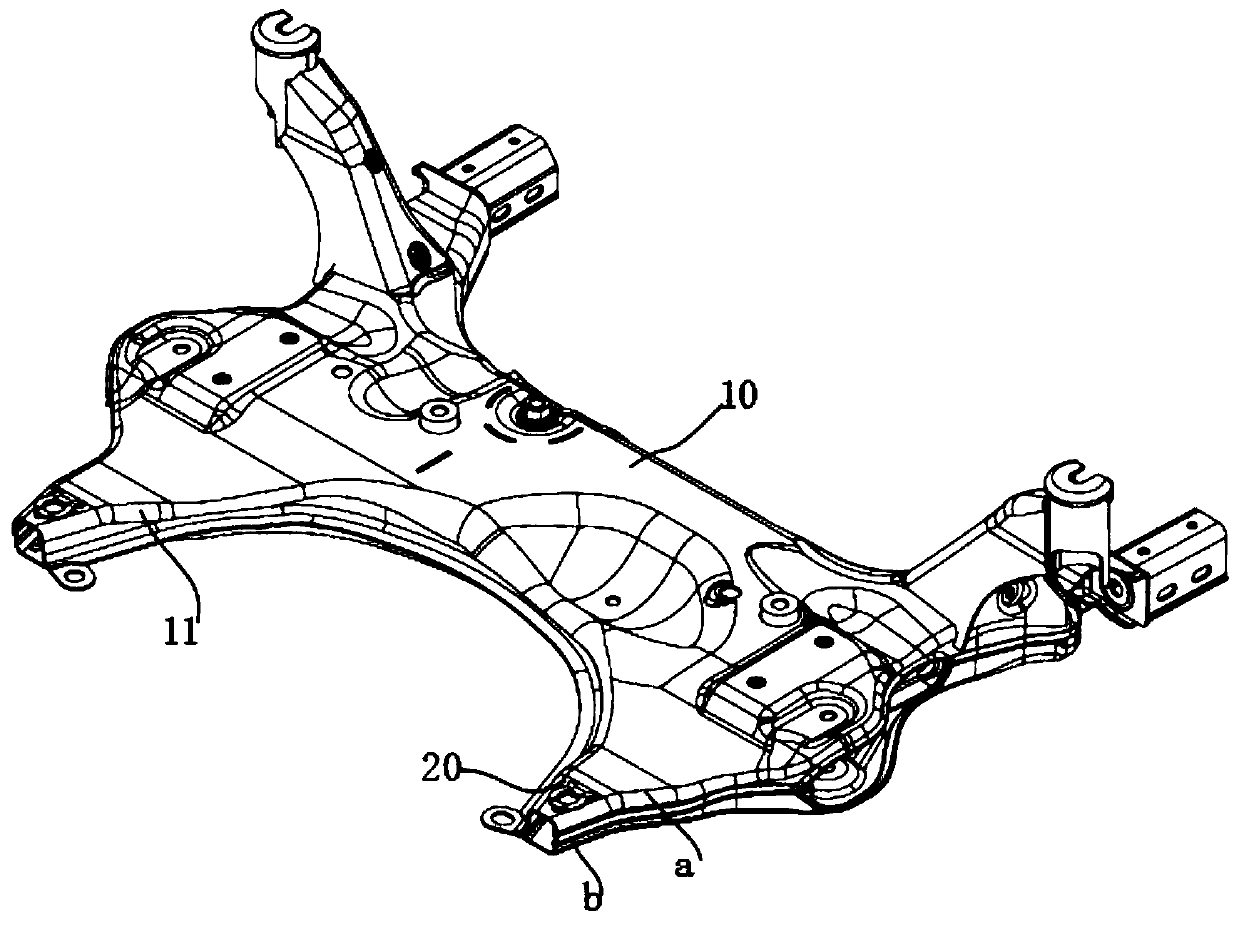

[0012] like Figure 3-Figure 6 As shown, a sub-frame structure includes a sub-frame body 10, and support arms 11 are symmetrically arranged on the left and right sides of the sub-frame body 10, and ball spacers 20 are arranged on the support arms 11, and the ball spacers 20 It includes a gasket body 21 fixedly connected to the support arm 11 , on which a steel ball 23 is riveted, and the steel ball 23 protrudes from the upper surface of the gasket body 21 . After the gasket body 21 is installed on the support arm 11, it is tightened with the vehicle body, and the steel ball 23 is engaged with the body sheet metal and the upper plate of the sub-frame under relatively high pressure, thereby ensuring that the sub-frame is relatively large relative to the vehicle body. There is no abnormal slipping noise under the impact load, which can well ensure the installation stability of the sub-frame and suspension system.

[0013] The spacer body 21 is in the shape of an annular plate as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com