Industrial sewing machine with electronic stitch length adjusting mechanism

A technology for adjusting needle distance and lockstitch sewing machine, which is applied to sewing equipment, sewing machine components, control devices for sewing machines, etc., can solve the problems of inability to use reverse stitching functions at the same time, inability to lock well, and poor stitch distance coincidence, etc. Achieve the effect of simple structure, reliable needle distance and less mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

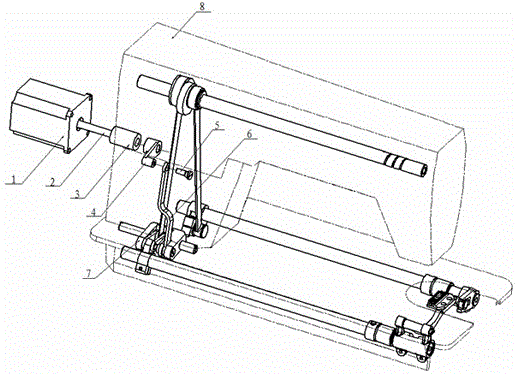

[0014] see figure 1 : a kind of industrial lockstitch sewing machine with electronic needle distance adjustment mechanism, including head 8, also includes stepper motor 1, stitch length adjustment crank 7 and stitch length adjustment connecting rod 6, and described stepper motor 1 is arranged on On the right end face of the machine head 8, the motor shaft 2 of the stepping motor 1 is arranged on the shaft sleeve 3 on the machine head 8, and the front end of the motor shaft 2 is fixed with a crank 4, and the structure of the crank 4 is "Z" The upper and lower sides of the "Z" type are cylinders, and there is a hole in the middle of the cylinder. The upper cylindrical hole is sleeved on the motor shaft 2, and the lower cylindrical hole is connected to one end of the needle distance adjustment connecting rod 6 through a screw 5. The needle distance adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com