Processing process method for outer ring

A processing technology and outer ring technology, which is applied in the field of outer ring processing technology, can solve the problems of easy wear of rollers and grooves, slow wire speed, and low dimensional accuracy of grooves, so as to achieve reasonable optimization of cutting process design and prevent abnormalities. impact problems, optimize the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

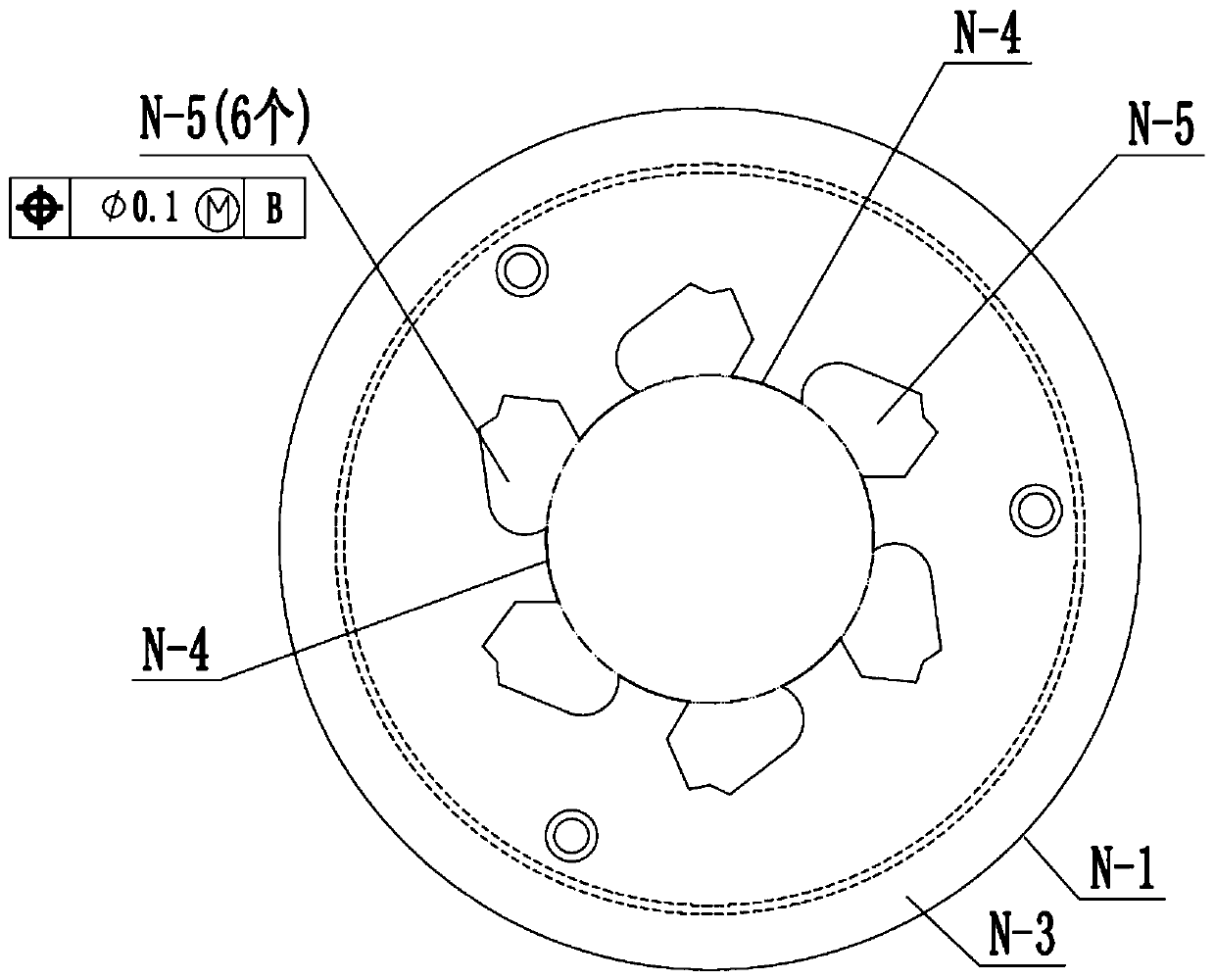

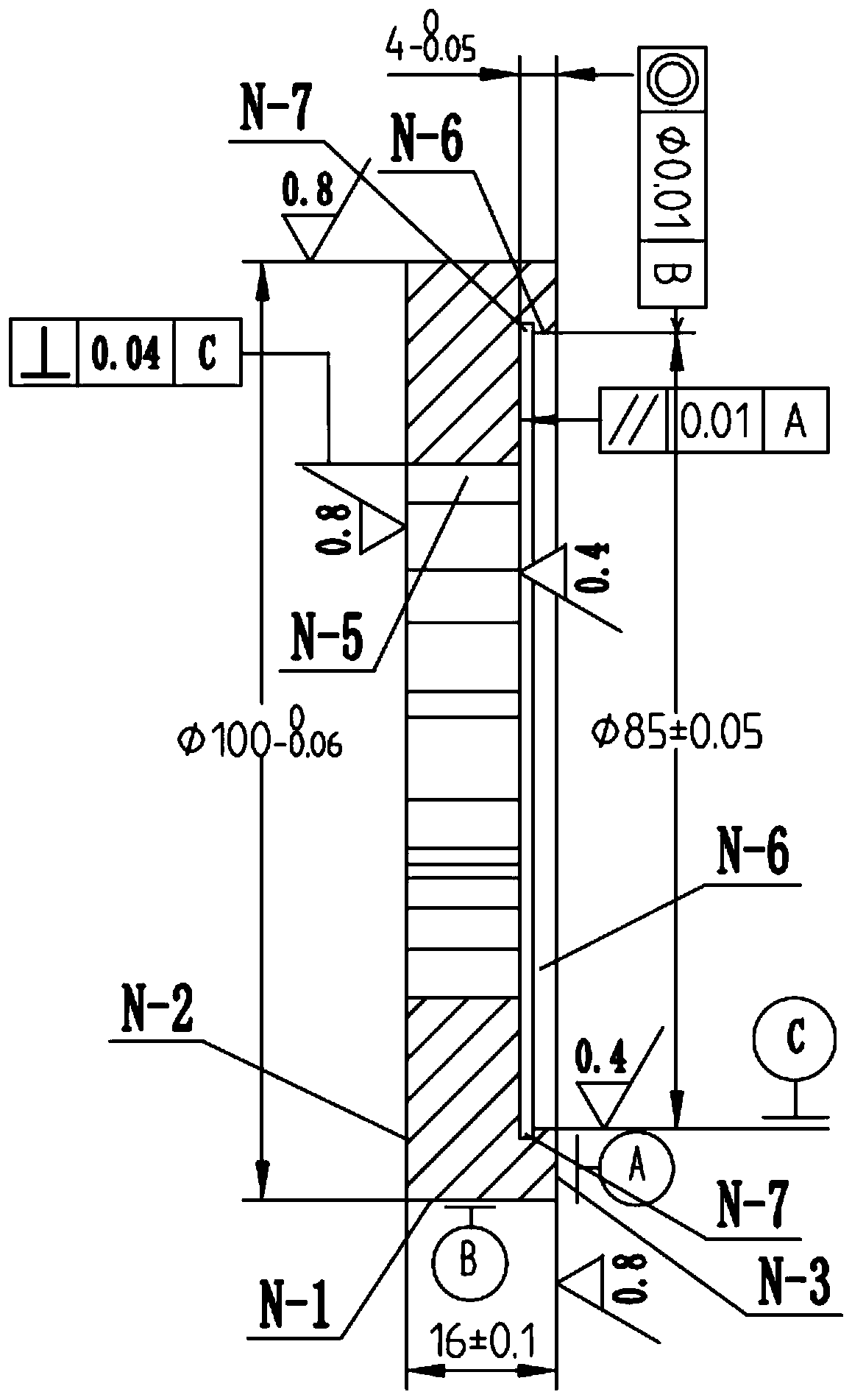

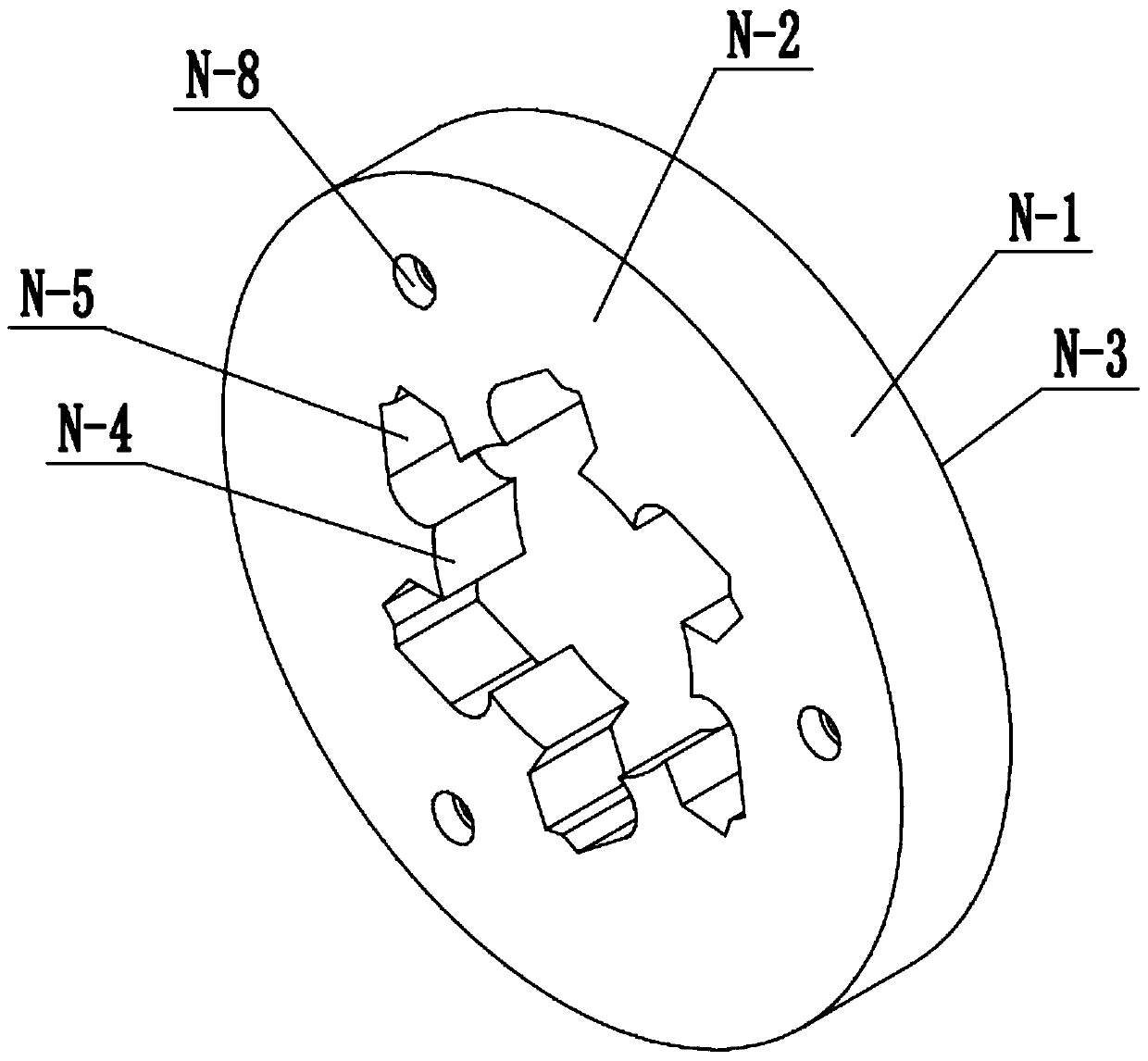

[0049] Embodiment one: see Figure 1-6 , a processing method for an outer ring, the outer ring is made of 20Cr material, characterized in that it comprises the following steps:

[0050] S10 forging to obtain blank;

[0051] S20 rough turning the outer circle N-1, the first end face N-2, the second end face N-3 and the inner hole N-4 in sequence;

[0052] S30 broaching groove N-5;

[0053] S40 extrusion groove N-5;

[0054] S50 cleans the cutting and oil stains on the surface of parts;

[0055] S60 finish turning the inner hole N-4, the first end face N-2, the outer circle N-1, the sinking table N-6, the relief groove N-7 and the second end face N-2 in sequence, and the sinking table N- The diameter and depth of 6 leave machining allowance;

[0056] S70 inspection size;

[0057] Deburring the edge of the N-5 mouth of the S80 file groove;

[0058] S90 drilling N-8;

[0059] S100 heat treatment;

[0060] S110 heat treatment inspection;

[0061] S120 shot blasting;

[0...

Embodiment 2

[0076] Embodiment two: see Figure 1-6 , a processing method for an outer ring, the outer ring is made of 20Cr material, characterized in that it comprises the following steps:

[0077] S10 forging to obtain blank;

[0078] S20 rough turning the outer circle N-1, the first end face N-2, the second end face N-3 and the inner hole N-4 in sequence;

[0079] S30 broaching groove N-5;

[0080] S40 extrusion groove N-5;

[0081] S50 cleans the cutting and oil stains on the surface of parts;

[0082] S60 finish turning the inner hole N-4, the first end face N-2, the outer circle N-1, the sinking table N-6, the relief groove N-7 and the second end face N-2 in sequence, and the sinking table N- The diameter and depth of 6 leave machining allowance;

[0083] S70 inspection size;

[0084] Deburring the edge of the N-5 mouth of the S80 file groove;

[0085] S90 drilling N-8;

[0086] S100 heat treatment;

[0087] S110 heat treatment inspection;

[0088] S120 shot blasting;

[0...

Embodiment 3

[0103] Embodiment three: see Figure 1-6 , a processing method for an outer ring, the outer ring is made of 20Cr material, characterized in that it comprises the following steps:

[0104] S10 forging to obtain blank;

[0105] S20 rough turning the outer circle N-1, the first end face N-2, the second end face N-3 and the inner hole N-4 in sequence;

[0106] S30 broaching groove N-5;

[0107] S40 extrusion groove N-5;

[0108] S50 cleans the cutting and oil stains on the surface of parts;

[0109] S60 finish turning the inner hole N-4, the first end face N-2, the outer circle N-1, the sinking table N-6, the relief groove N-7 and the second end face N-2 in sequence, and the sinking table N- The diameter and depth of 6 leave machining allowance;

[0110] S70 inspection size;

[0111] Deburring the edge of the N-5 mouth of the S80 file groove;

[0112] S90 drilling N-8;

[0113] S100 heat treatment;

[0114] S110 heat treatment inspection;

[0115] S120 shot blasting;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com