Transverse stabilization bar mounting structure used for vehicle

A technology for a stabilizer bar and mounting structure, applied in vehicle components, transportation and packaging, interconnection systems, etc., can solve problems such as assembly difficulties, affecting driving comfort, performance degradation, etc., to improve reliability and durability. The effect of improving wear failure and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

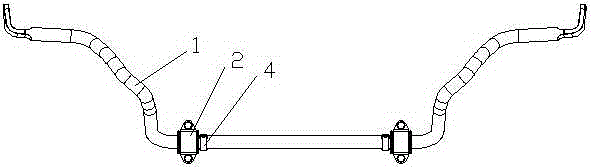

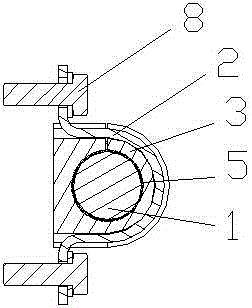

[0020] see Figure 1-Figure 3 , it can be seen from the figure that the vehicle stabilizer bar installation structure of the present invention, the straight section in the middle of the stabilizer bar 1 is fixedly installed on the sub-frame assembly through two pressure plates 2 at a certain distance and combined with bolts 8, and is connected with the pressure plate 2 The stabilizer bar 1 corresponding to the press-fitting position is covered with a rubber bushing 3, and the pressure plate fixes the stabilizer bar on the subframe assembly through the rubber bush. Two limit clamps 4 are fixed on the stabilizer bar 1, and the two limit clamps 4 are respectively located on the side of the rubber bush 3 (inside in the embodiment) to prevent the stabilizer bar 1 from moving left and right. When the stabilizer bar moves to the left, because the position of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com