Steering gear gap adjustment mechanism

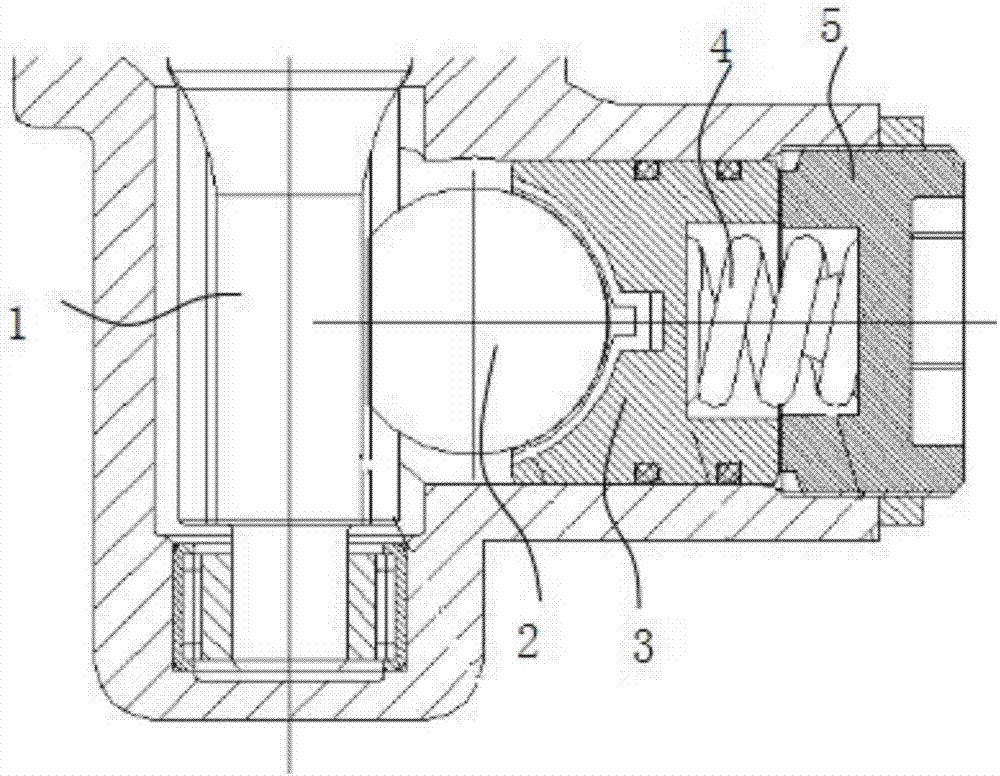

A gap adjustment mechanism and steering gear technology, which is applied to mechanical steering gears, mechanical equipment, portable lifting devices, etc., can solve problems such as inability to perform gap compensation, increased space occupied by the coil spring 4, and insignificant improvement in abnormal noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

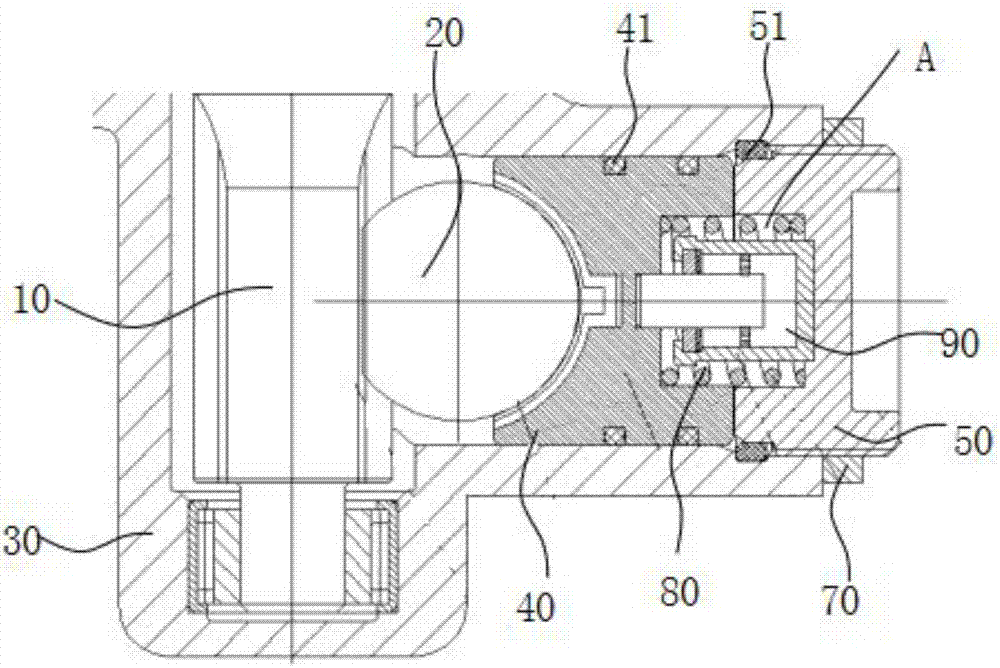

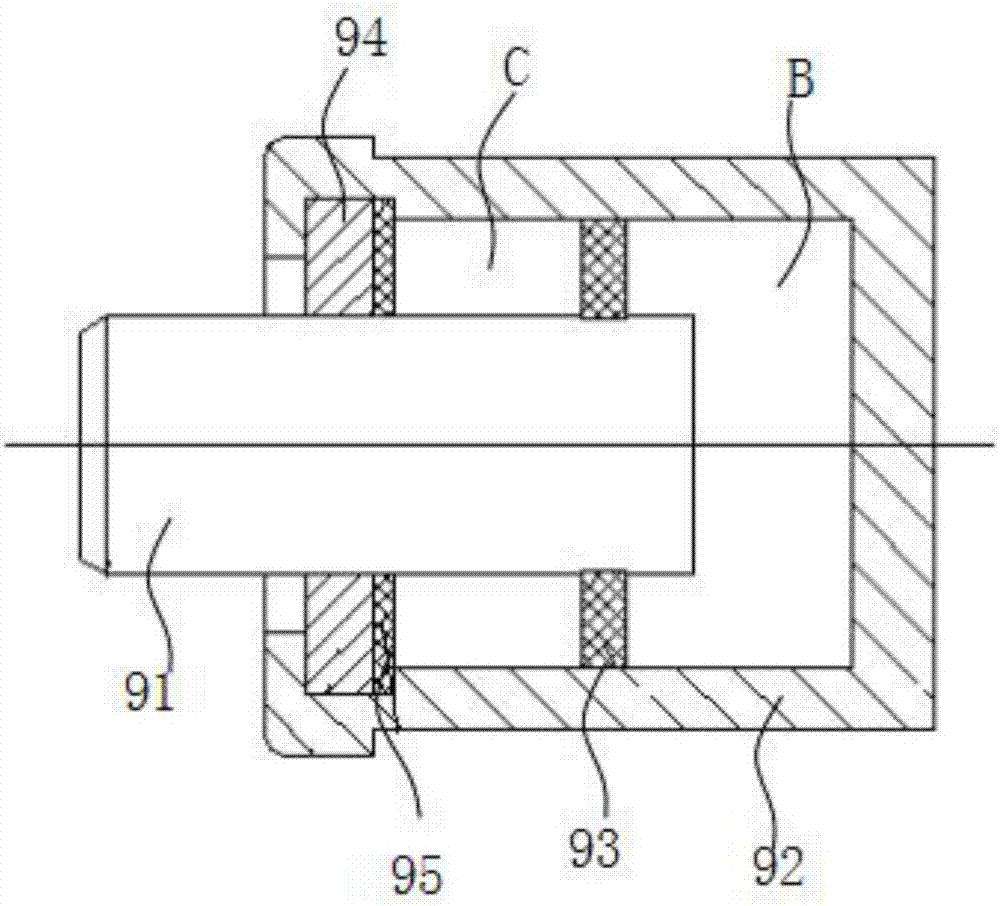

[0010] Such as figure 2 As shown, a steering gear gap adjustment mechanism includes a steering input gear shaft 10 and a rack 20 that mesh with each other, and a pressure block 40 that is in contact with the rack 20 is arranged in the steering gear housing 30 on one side of the rack 20 , the port of the steering gear housing 30 is provided with an adjusting screw plug 50 that limits the position of the briquetting block 40 , the adjusting screw plug 50 is sleeved with a lock nut 70 for locking its position, and the briquetting block 40 and the adjusting screw plug 50 are provided with There are recesses with opposite openings, and the two recesses are butted to form a chamber A. A coil spring 80 is arranged in the chamber A. One end of the coil spring 80 is abutted against the pressure block 40, and the other end is abutted against the adjusting screw plug 50. The chamber A A damping unit 90 is also provided inside, the end of the piston rod 91 of the damping unit 90 abuts ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com