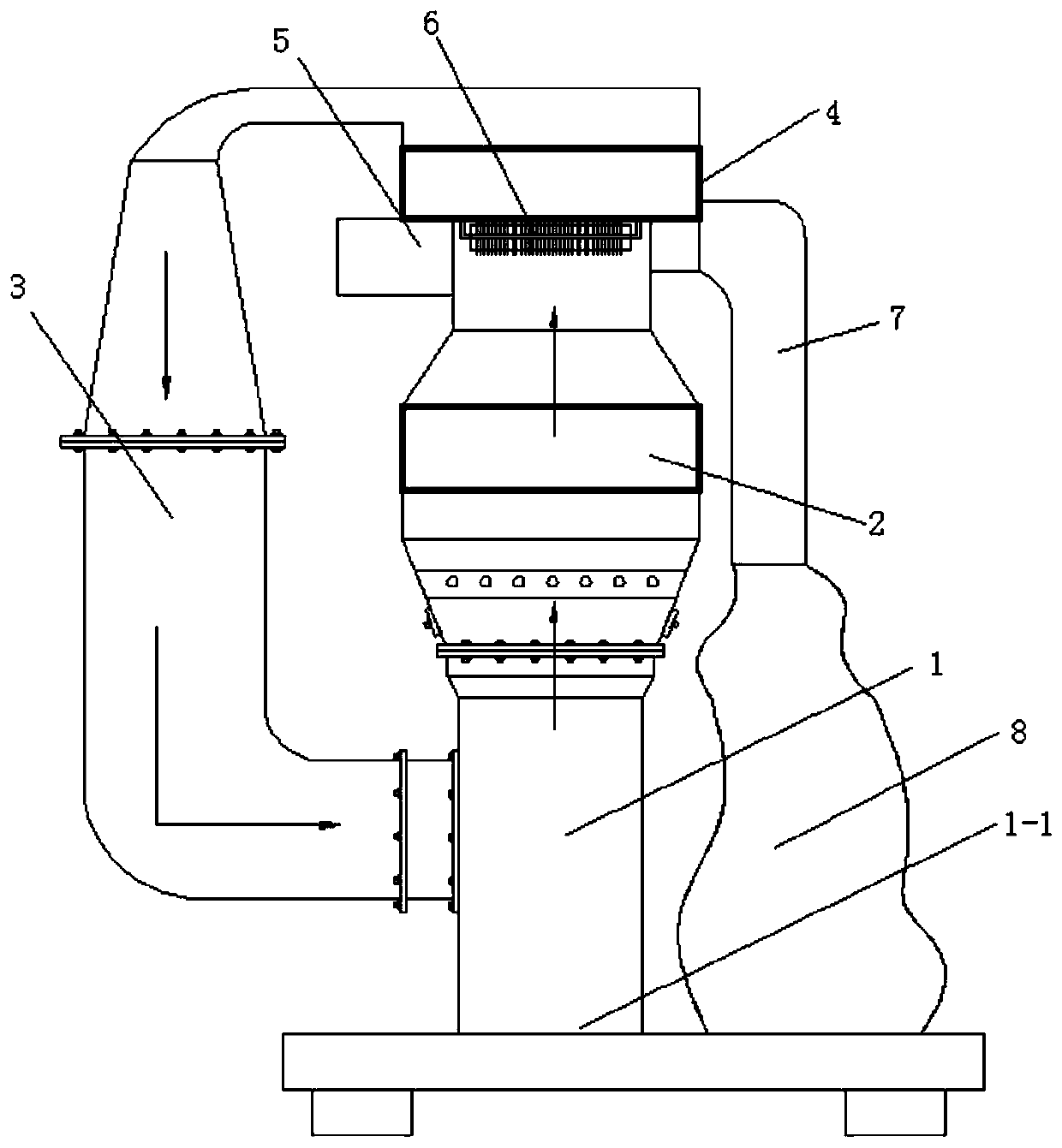

Anti-blocking suction device of winnowing and impurity removal equipment of stem screening line

A technology of air separation, impurity removal, and suction device, which is applied in the preparation of tobacco, solid separation, and separation of solids from solids by air flow. , The effect of simple structure and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

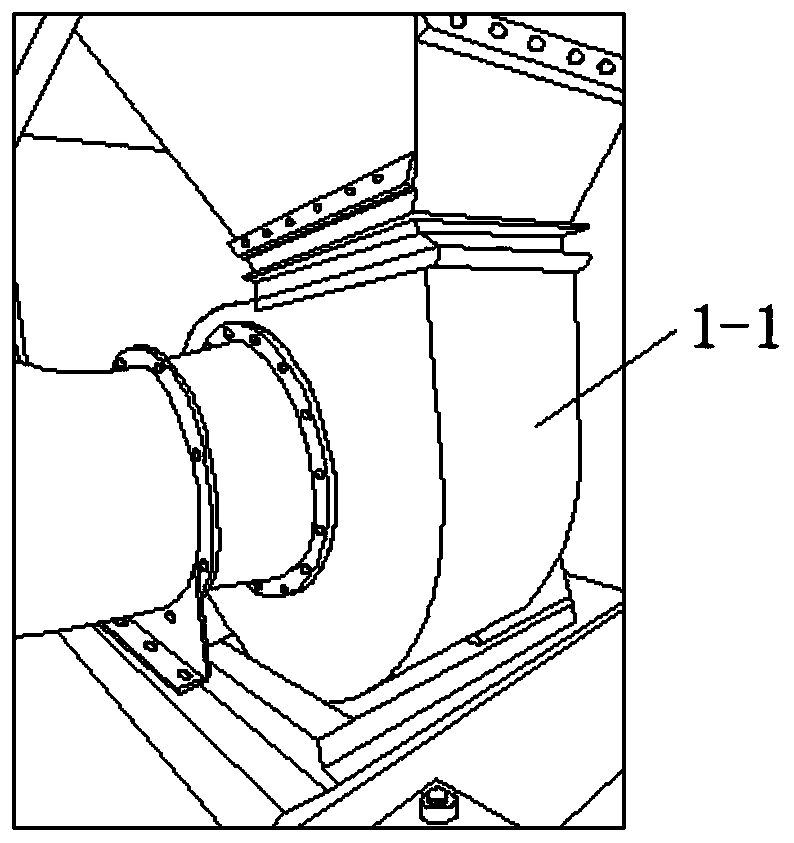

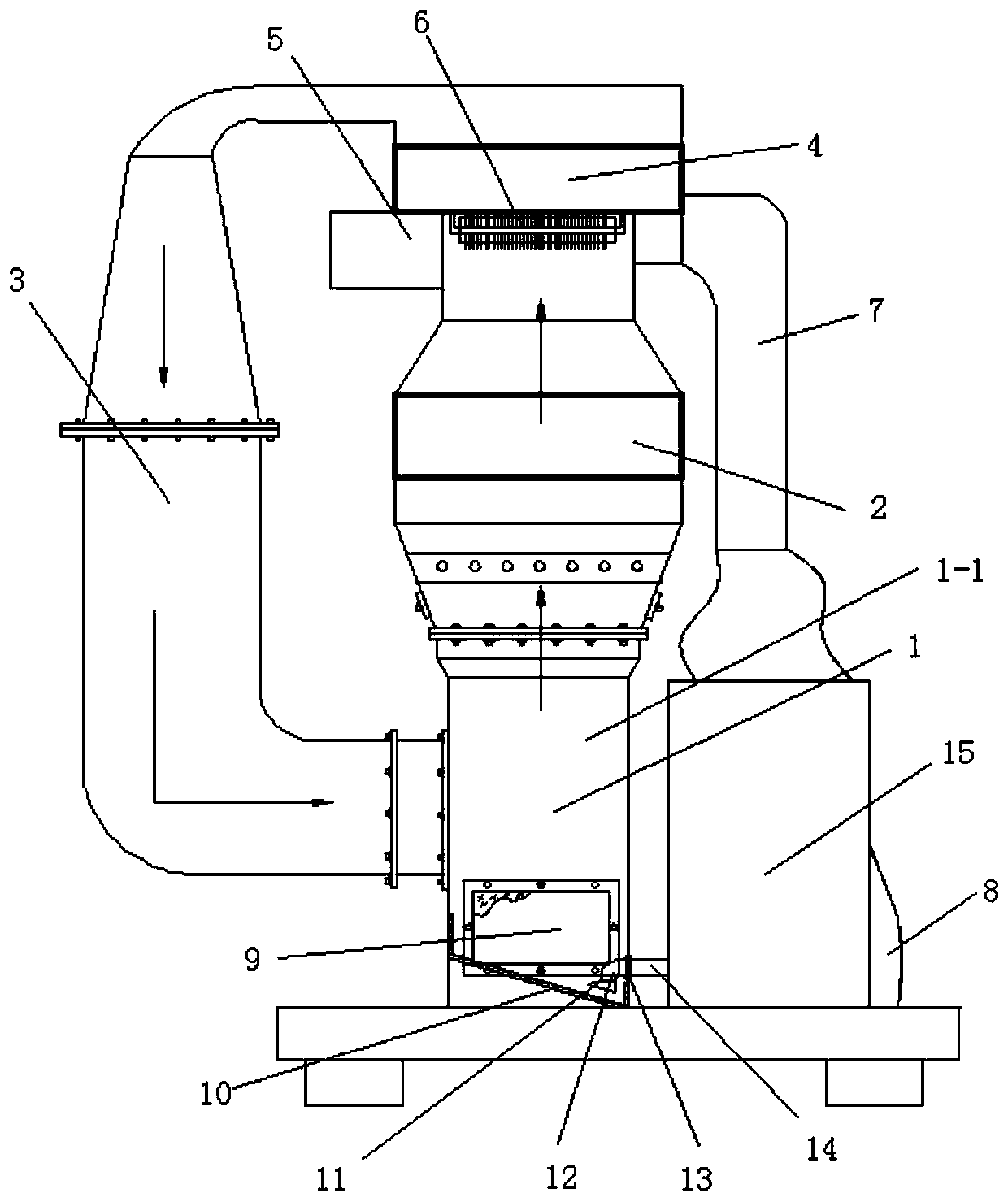

Embodiment Construction

[0030] Attached below Figure 3-11 Specific examples of the present invention are described. It should be understood that the embodiments described below are only illustrative rather than specific limitations on the present invention.

[0031] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The control methods in the following examples are conventional control methods unless otherwise specified. The component materials used in the following examples are commercially available unless otherwise specified. In the following embodiments, the timer controls the automatic timing start-stop control circuit of the impurity removal fan motor through a relay, all of which are conventional control methods.

[0032] In the present invention, unless stated otherwise, it should be understood that the terms "center", "upper", "lower", "front", "rear", "left", "right", "vertical The orientations or positional relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com