Oil return control method of inverter compressor and air conditioner

A variable frequency compressor and oil return control technology, which is applied in the field of oil return control of variable frequency compressors and air conditioners, can solve the problems of high oil discharge rate of compressors, lack of oil in compressors, etc., to avoid wear and solve high frequency return poor oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

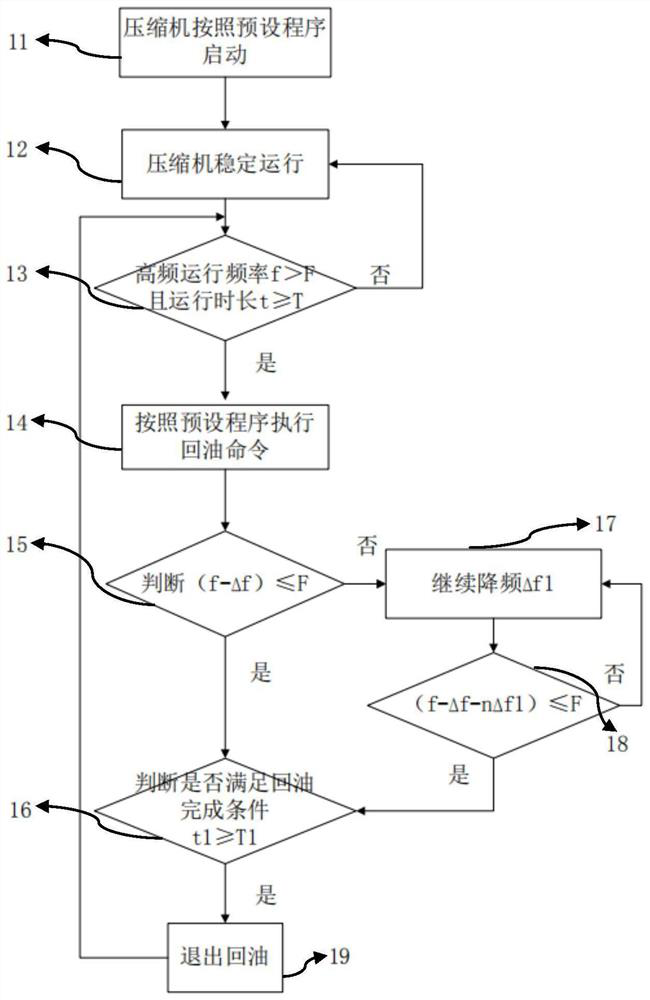

Embodiment approach 2

[0078] In the second embodiment, the frequency reduction of the high-frequency operating frequency f of the compressor is carried out, instead of directly reducing the frequency of the compressor from the current high-frequency operating frequency f to the fixed compressor preset frequency F in the first embodiment, but at On the basis of the high-frequency operating frequency f of the compressor, the frequency is reduced step by step, so as to avoid fluctuations or abnormalities caused by excessive frequency reduction of the high-frequency operating frequency f of the compressor.

[0079] Specifically, in this embodiment, the high-frequency operating frequency f of the compressor is controlled to reduce the first preset frequency reduction Δf, and then judge whether the frequency requirement for oil return is met, and then reduce the second preset frequency reduction Δf step by step if it is not satisfied 1 , until the frequency that satisfies oil return is reached, since Δf>Δ...

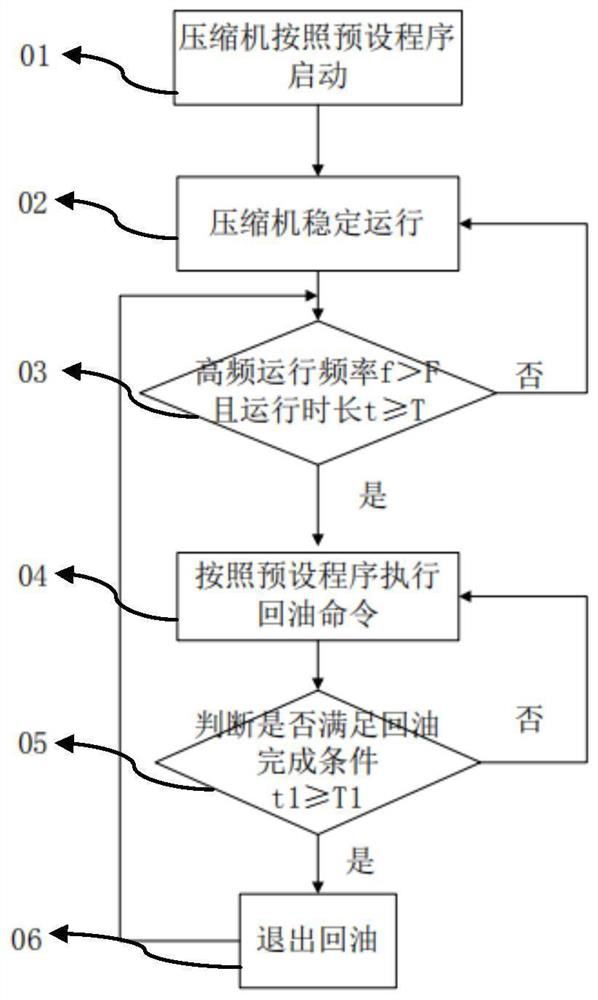

Embodiment 1

[0117] see figure 1 As shown, the oil return control method of the inverter compressor in this embodiment includes:

[0118] Step 01, the compressor is started according to the preset program.

[0119] The starting mode of the compressor is started according to the original preset program, which can be a variety of starting modes such as normal speed start, fast start, overload start, etc.

[0120] Step 02, the compressor runs stably.

[0121] The compressor runs to the target frequency and runs stably according to the original setting procedure.

[0122] Step 03, judging whether the oil return condition for frequency reduction is satisfied. Obtain the stable operating frequency f at this time, and judge whether f exceeds the preset high-frequency oil return judgment frequency F. If f>F, and the stable operation time t exceeds the preset time T, it indicates that the frequency reduction oil return condition has been met at this time , go to the next step, otherwise go to s...

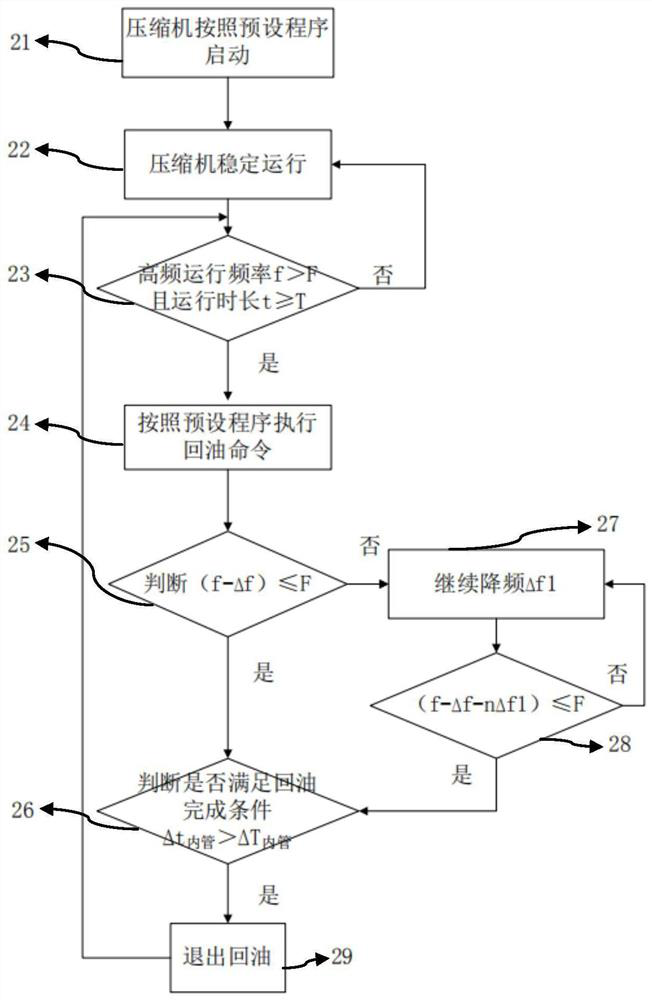

Embodiment 3

[0135] see image 3 As shown, the difference between the oil return control method of the inverter compressor in this embodiment and the second embodiment lies in the different conditions for judging the completion of oil return in step 16 . Embodiment 1 By judging whether the running time t1 exceeds the preset oil return time T1 (such as Figure 5 ), the present embodiment judges whether the oil return is completed by the temperature change of the inner pipe (such as Figure 6 ). If after the oil return program is executed, the inner pipe temperature drop value Δt inner pipe exceeds the set temperature difference ΔT inner pipe, indicating that the frequency reduction at this time has a greater impact on the temperature change of the inner pipe, which may affect the outlet air temperature, thereby affecting indoor comfort property, exit the oil return at this time. If the Δt inner tube ≤ ΔT inner tube, it means that the temperature drop of the inner tube is within the accep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com