Oil return flow path for multi-connected compressors and control method of oil return flow path

A control method and compressor technology, which is applied in the direction of compressors, refrigerators, refrigeration components, etc., can solve the problem of difficult oil return control of multi-line compressors, and achieve the effect of ensuring oil volume and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

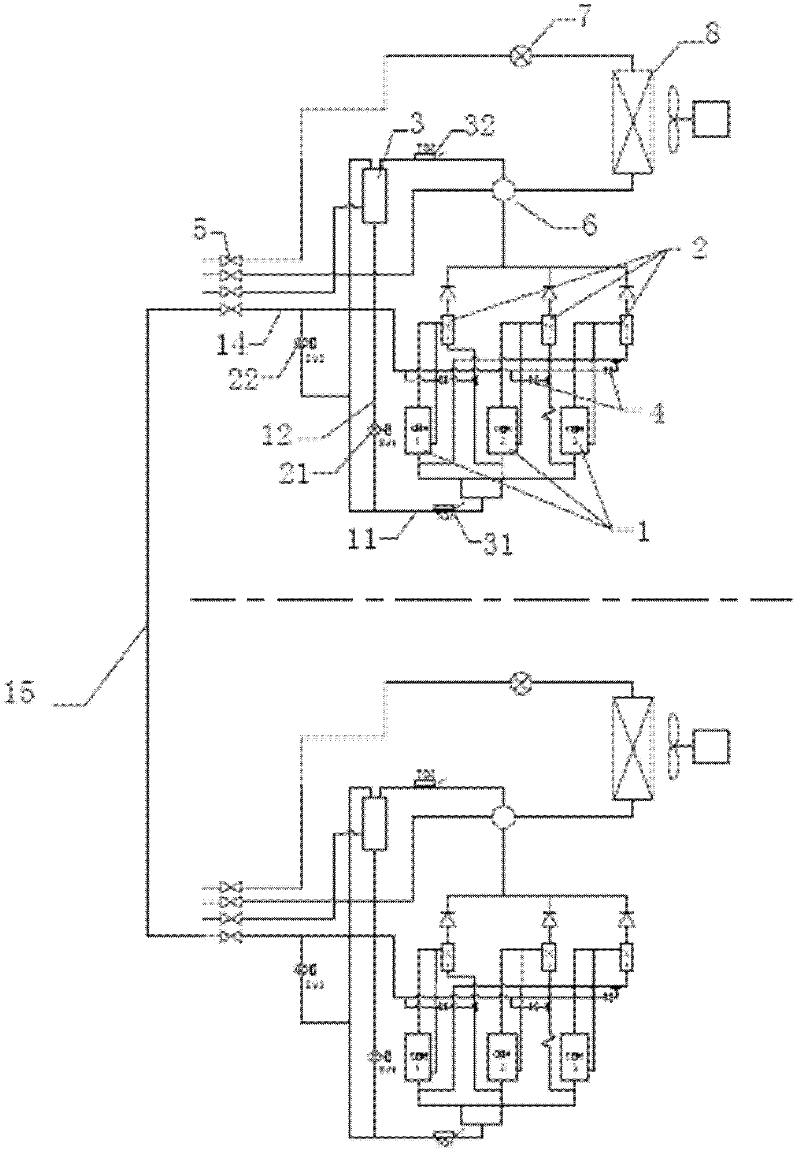

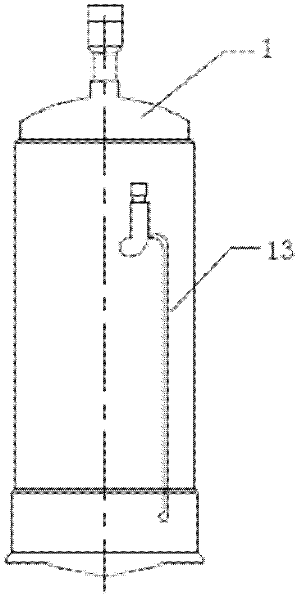

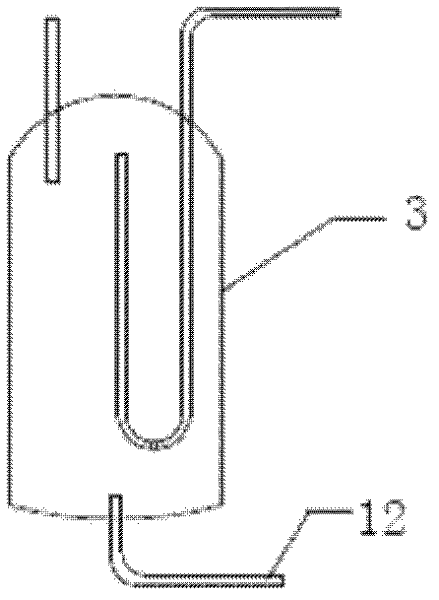

[0031] See attached Figure 1-3 , the multi-connected outdoor unit is composed of N outdoor units connected in parallel, and each outdoor unit has M compressors connected in parallel, where N and M are integers of 2-5, which are more suitable. The outdoor unit is mainly composed of compressor 1, oil separator 2, stop valve 5, four-way valve 6, condenser 8, electronic expansion valve 7, one-way valve, liquid storage tank 3, first electronic valve 21 (SV1), second It consists of two electronic valves 22 (SV2). The air return pipes of M compressors are connected to the main air return pipe 11, and the main air return pipe 11 is connected to the liquid storage tank 3. The first temperature sensor 31 (TQ1) is installed on the main air return pipe of the compressors, and the liquid storage tank of each outdoor unit A second temperature sensor 32 (TQ2) is arranged on the pipeline to the four-way valve. Each oil separator of each outdoor unit is connected to the oil balance pipe 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com