Lubrication structure of rotary spline

A lubricating structure and spline technology, applied in the field of the spline lubricating structure of the wind power gearbox, can solve the problems of weakening the strength of the spline shaft, unfavorable product quality control and cost control, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

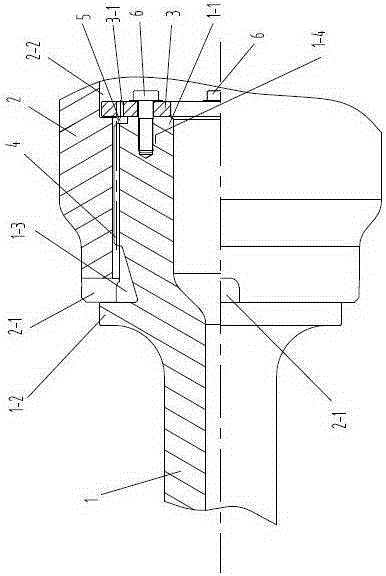

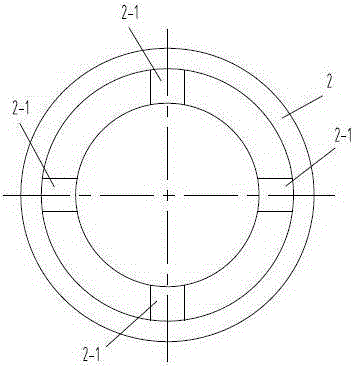

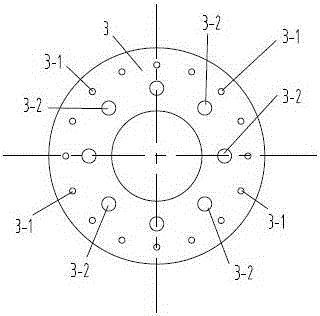

[0016] Such as figure 1 , 2 , 3, the lubricating structure of a rotary spline of the present invention includes a spline shaft 1, a spline sleeve 2 and a pressure plate 3, and the spline shaft 1 and the spline sleeve 2 rely on the spline pair 4 to cooperate, so There is an oil discharge hole 3-1 on the pressure plate 3, the pressure plate 3 is fixed on the free end 1-1 of the spline shaft 1, and is offset against one end of the spline sleeve 2, and the free end of the spline shaft 1 is A shoulder 1-2 is provided at the opposite spline end of 1-1, and the shoulder 1-2 is offset against the other end of the spline sleeve 2, and several Circumferentially distributed radial oil collection grooves 2-1, the spline end of the spline shaft 1 opposite to the free end 1-1 also has a circumferential inclined bottom oil chamber 1-3, and the circumferential inclined bottom oil chamber One end of 1-3 communicates with the radial oil collection groove 2-1 distributed in the circumferential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com