Internal circulating low nitrogen gas burner

A gas burner and internal circulation technology, which is applied to gas fuel burners, burners, flue gas combustion, etc., can solve the problems of flue air duct corrosion, increased investment cost, hidden safety hazards, etc., and reduce the production of nitrogen oxides. , the effect of eliminating potential safety hazards and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0028]

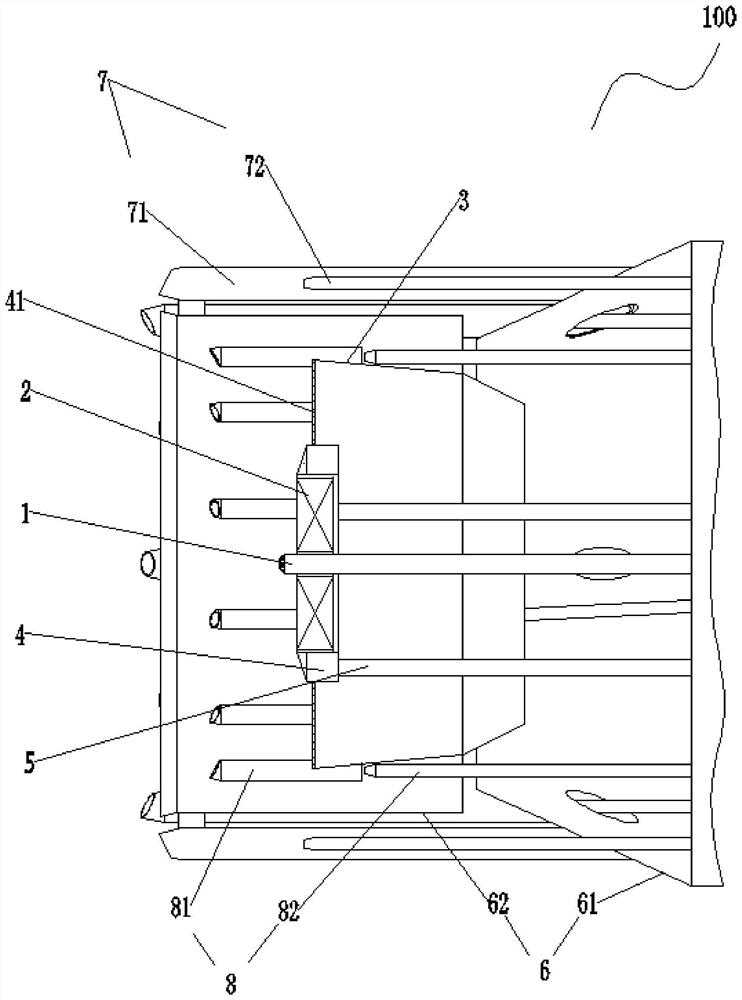

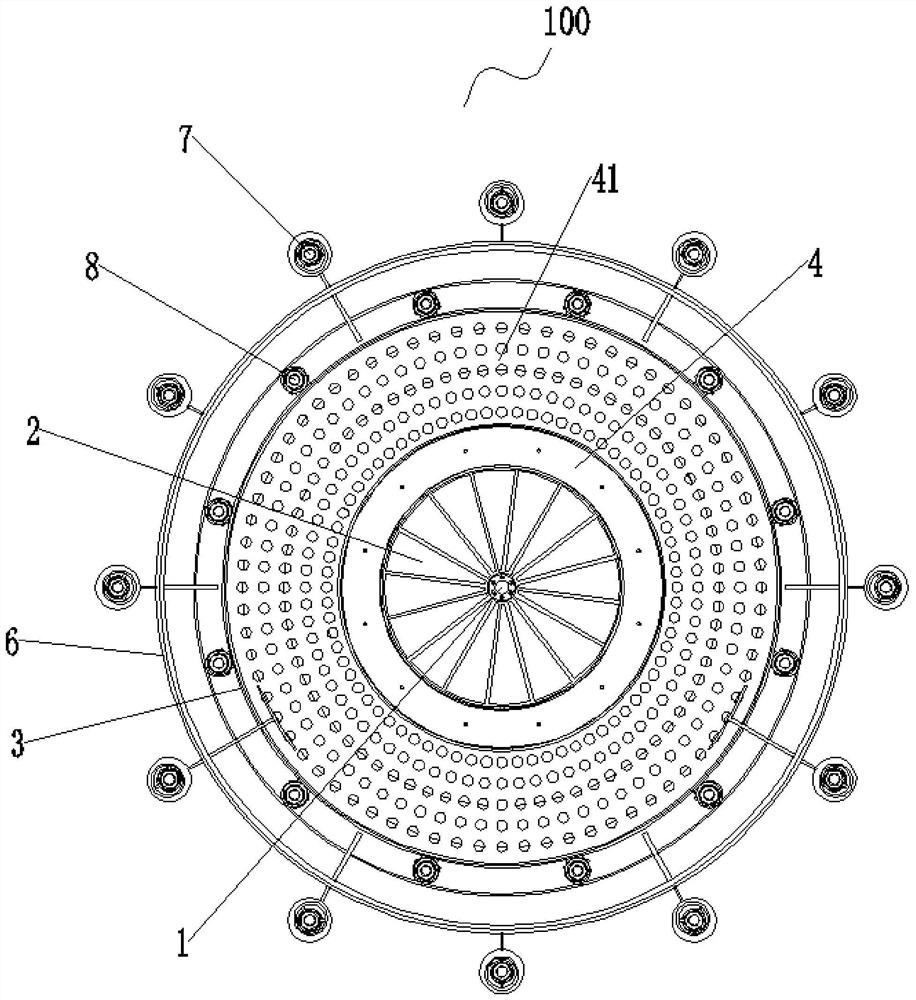

[0029] figure 1 It is the front view of the internal circulation low nitrogen gas burner in the embodiment of the present invention. figure 2 It is the right side view of the internal circulation low nitrogen gas burner in the embodiment of the present invention.

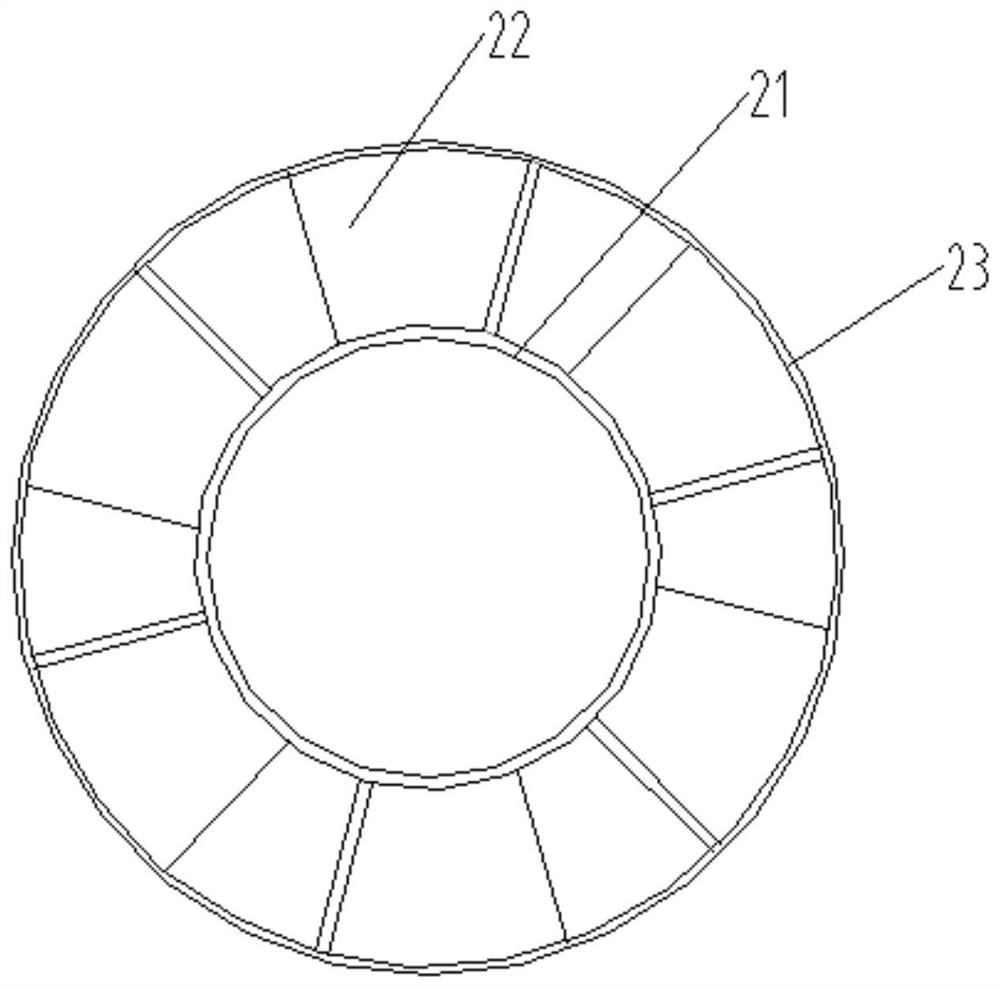

[0030] Such as figure 1 , figure 2 As shown, the internal circulation low-nitrogen gas burner 100 in this embodiment includes a first gas pipe 1, a swirler 2, a shunt pipe 3, an annular gas head 4, a second gas pipe 5, a flow barrier 6, and multiple sets of Outer ring gas gun assembly 7 and multiple sets of inner ring gas gun assemblies 8 .

[0031] The first gas pipe 1 is a round pipe, and one end of the first gas pipe 1 is equipped with a gas he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com