Temperature adjusting system for power lithium battery pack and power lithium battery pack

A technology for temperature regulation and lithium battery packs, applied in lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problem of reducing the actual power density and energy density of batteries, affecting the packaging and sealing of lithium battery modules, and having a large and complex structure, etc. problems, to achieve the effect of increasing thermal conductivity, stable shape, and compensating for low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

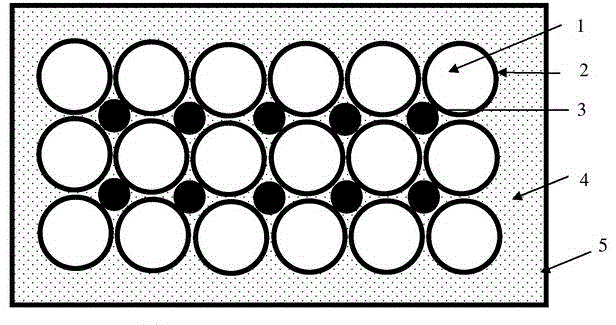

[0028] Such as figure 1, Embodiment 1 The temperature regulation system of the power lithium battery pack uses the built-in phase change microcapsules and heat pipes to realize the intelligent temperature regulation of the power lithium battery pack. The system includes: a battery case 5; several lithium battery units 1 arranged in the battery case 5, and a thermally conductive coating 2 is coated on the surface of the lithium battery unit 1; filled in the battery case 5, the lithium battery units 1 between the phase change energy storage microcapsules 4, each lithium battery unit 1 is in contact with the phase change energy storage microcapsules 4 through the thermally conductive coating 2 on its surface; and, inserted between the lithium battery units 1 Between several heat pipes 3, the peripheral wall of each heat pipe 3 is in contact with the phase-change energy storage microcapsules 4, and the two ends of each heat pipe 3 are in close contact with the upper cover and the ...

Embodiment 2

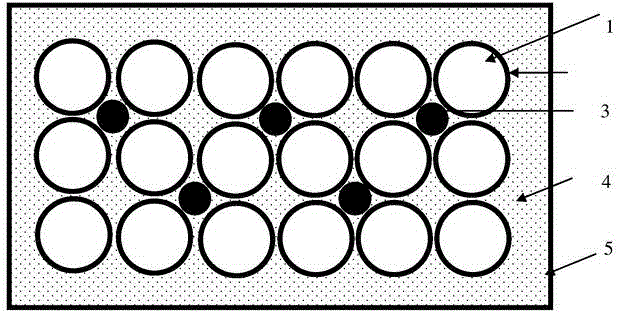

[0033] figure 2 It is a top view schematic diagram of the temperature regulation system of the power lithium battery pack in the second embodiment. Wherein, 5 is a battery box, 1 is a lithium battery unit, 2 is a thermally conductive coating coated on the surface of the lithium battery unit 1, and 3 is a top cover inserted in the phase change energy storage microcapsule 4 and connected to the battery box 5 1, the heat pipe in close contact with the bottom plate, 4 is the phase-change energy storage microcapsules filled in the battery box 5 and between the lithium battery units 1 .

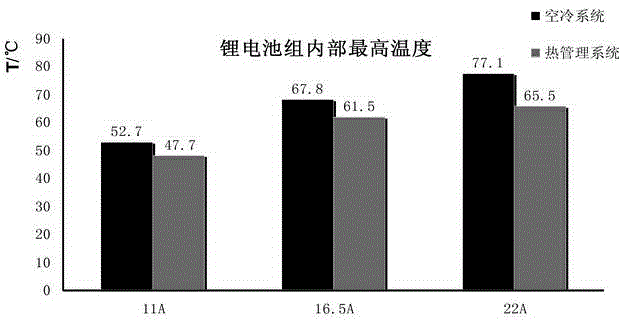

[0034] Embodiment 2 The system is applied to a power lithium battery pack with a rated voltage of 48V and a capacity of 11Ah. The lithium battery unit 1 uses a 3.7V 18650 lithium battery unit, and the thermally conductive coating 2 uses a high thermally conductive silicone grease with a thermal conductivity of 0.95. W / m·k, the heat pipe 3 adopts a copper-methanol heat pipe, the capsule core mater...

Embodiment 3

[0037] refer to figure 1 , The basic layout of the temperature regulation system structure of the power lithium battery pack of the third embodiment is the same as that of the first embodiment. Wherein, 5 is a battery box, 1 is a lithium battery unit, 2 is a thermally conductive coating coated on the surface of the lithium battery unit 1, and 3 is a top cover interspersed in the phase-change energy storage microcapsule and connected to the battery box 5, The heat pipe 4 in contact with the bottom plate is a phase-change energy storage microcapsule filled in the battery case 5 and between the lithium battery units 1 .

[0038] Embodiment 3 The system is applied to a power lithium battery pack with a rated voltage of 32V and a capacity of 11Ah, wherein the lithium battery unit 1 adopts a 3.7V 18650 lithium battery unit; the thermal conductive coating 2 adopts a high thermal conductive silicone grease with a thermal conductivity of 1.2 W / m·k. The heat pipe 3 adopts a carbon ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com