Combustion chamber device for dispersing high-temperature reflux zone at boss

A high-temperature reflow and combustion chamber technology, which is applied in the direction of combustion chambers, continuous combustion chambers, and combustion methods, can solve the problems of increased thermal NOx emissions, reduce the generation of NOx, avoid heat accumulation, and increase flame stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

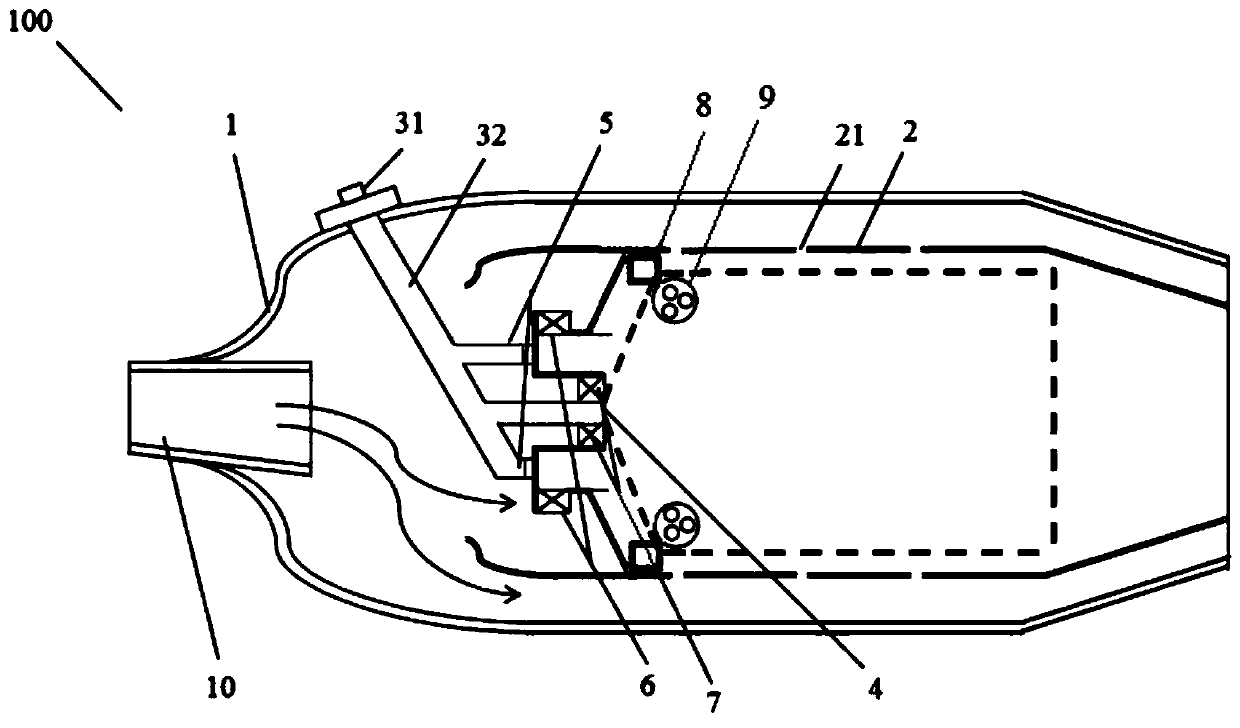

[0016] figure 1 It is a structural schematic diagram of a combustion chamber device in the high-temperature recirculation zone at the dispersion boss in the embodiment of the present invention.

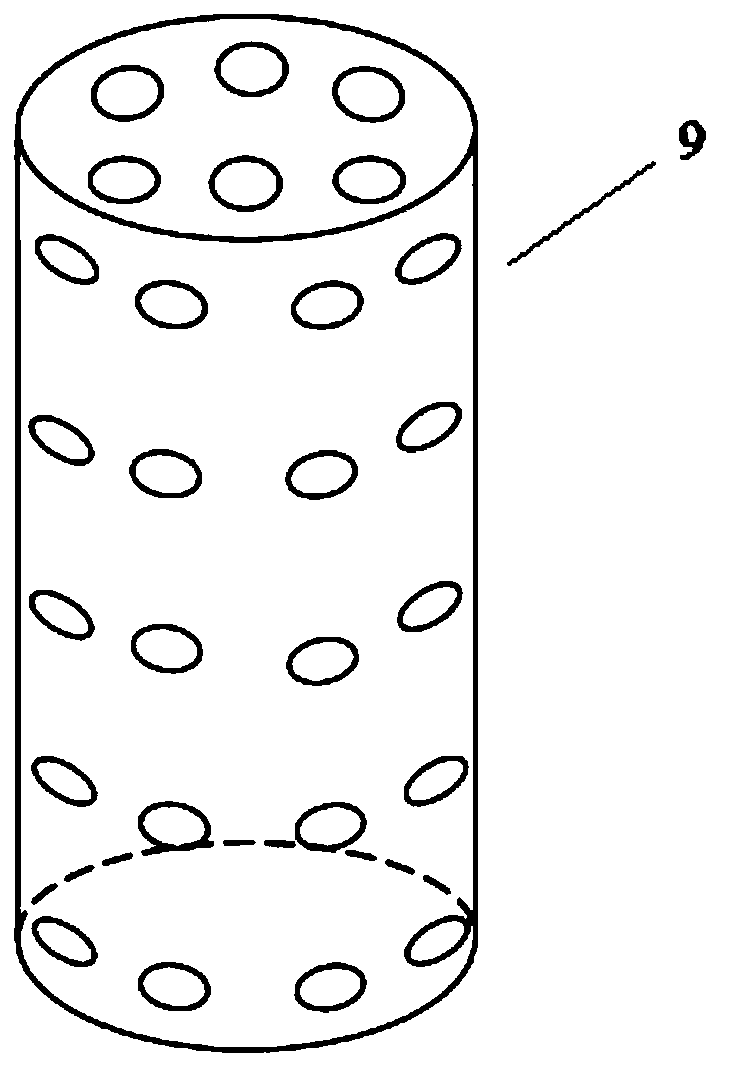

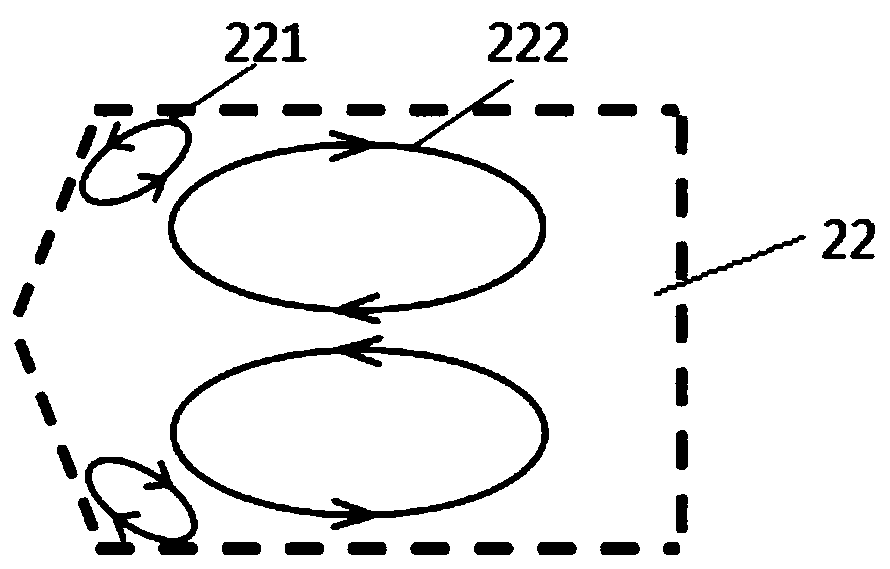

[0017] Such as figure 1 As shown, a combustion chamber device 100 in the high-temperature recirculation area at the dispersed boss in this embodiment has a casing 1, a flame tube 2, a fuel channel 3, an on-duty fuel channel 4, a fuel inlet channel 5, and a radial swirler 6. Axial cyclone 7 , boss 8 , porous cylinder 9 and diffuser channel 10 .

[0018] Receiver 1.

[0019] The flame tube 2 is arranged in the casing 1 and forms an annular cavity with the casing 1 .

[0020] The wall surface of the flame tube 2 is provided with a mixing hole 21 .

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com