Microorganism continuous culture device

A technology for culturing devices and microorganisms, which is applied in enzymology/microbiology devices, biochemical cleaning devices, biomass post-processing, etc., can solve the problems of limited effective aeration area, decreased aeration efficiency, fluctuation of aeration pore size, etc. Achieve the effect of avoiding uneven feed pressure and overflow speed, increasing the concentration of suspended bacteria and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

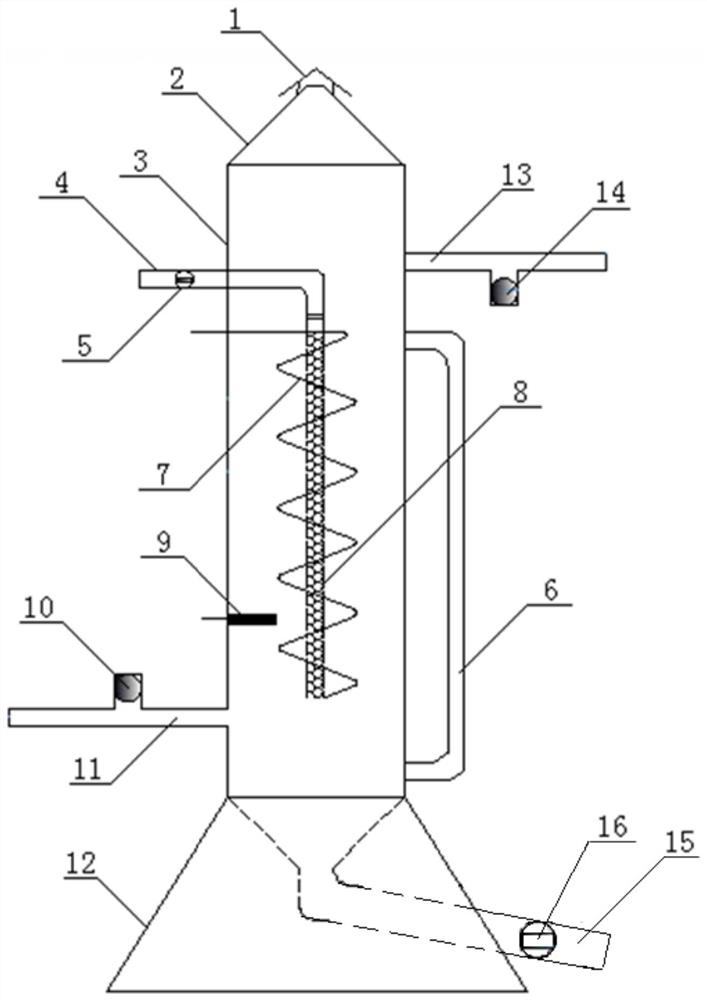

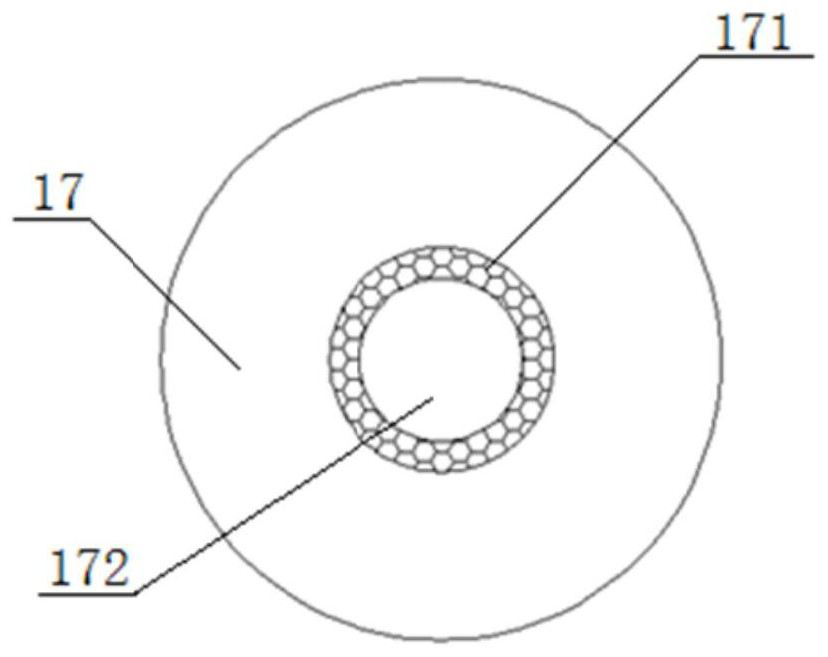

[0034] Such as Figure 2-7 As shown, the present invention includes a culture tank 3 and an aeration tube 8 arranged in the culture tank 3, and also includes a heating tube 7 surrounding the periphery of the aeration tube 8 and heating the culture solution in the culture tank 3, the aeration The tube 8 is also fixed with a plurality of baffles 17 distributed axially along the aeration tube 8. The baffles 17 are circular in shape and the center is sunken downwards. Holes 171 , the heating tube 7 spirals around the periphery of the aeration tube 8 , and the diameter of the spiral is larger than the diameter of the baffle plate 17 .

[0035] The culture tank 3 of the present invention is arranged on the base 12, and the upper base is a circular platform hollow structure, the height of the base is 1 / 5-1 / 6 of the total height of the device, and the radius of the bottom of the base is 1 / 3-1 / 4 of the total height of the device. The discharge pipe 15 is about 1 / 3-1 / 4 of the base heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com