Phase change heat storage element and heat storage and supply device adopting same

A phase-change heat storage and heat supply device technology, which is applied in the direction of household heat supply, heat storage equipment, and heat supply systems, can solve the problems of poor adaptability of heat sources, many heat exchange links, and long heat release time to achieve adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

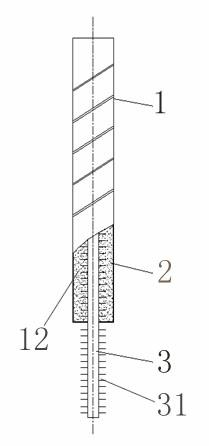

[0025] The structure of the phase change heat storage element of this embodiment is as attached figure 1 As shown, a housing 1 is included, and a hollow cavity 12 is provided inside the housing 1. The hollow cavity 12 is also provided with a heat pipe 3. The side of the heat pipe 3 is provided with fins 31, and one end of the heat pipe 3 is placed in the hollow cavity. Inside the body 12, the other end is exposed outside the shell 1, the hollow cavity 12 is filled with a phase change heat storage material 2, and the end of the heat pipe 3 placed in the hollow cavity 12 is surrounded by the phase change heat storage material 2 . In this embodiment, the casing 1 is a special-shaped tubular metal shell, and the number of heat pipes 3 can be one or more.

[0026] When the phase-change heat storage element of this embodiment is used, when heat is stored, the heat of the heat source is directly transferred to the phase-change heat storage material 2 in the hollow cavity 12 through ...

Embodiment 2

[0028] The structure of the phase change heat storage element of this embodiment is similar to that of Embodiment 1, the difference is that: the middle part of the heat pipe 3 is placed in the hollow cavity 12, and the two ends of the heat pipe 3 are exposed outside the casing 1, and the number of the heat pipe 3 can also be One or more.

[0029] When the phase change heat storage element of this embodiment is used, the heat from the heat source can be directly transferred to the phase change heat storage material 2 in the hollow cavity 12 through both ends of the heat pipe 3 .

Embodiment 3

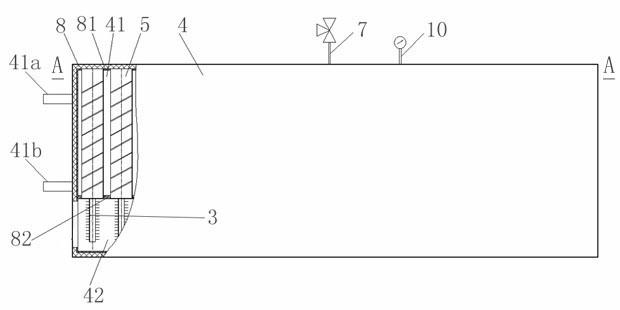

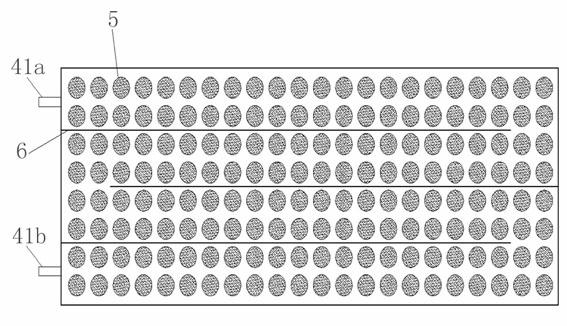

[0031] The heat storage heat supply device structure of this embodiment is as attached figure 2 , 3 As shown, the box body 4 is included, and the inner surface of the box body 4 is provided with an insulating layer 8. The outer shape of the box body 4 in this embodiment is a cuboid, and of course it can also be a cylinder or other polygonal prisms. The inside of the box body 4 is divided into a phase change heat storage chamber 41 and a heat supply heating chamber 42 by a partition plate 82. The phase change heat storage chamber 41 is provided with a cold water inlet 41a and a hot water outlet 41b, and the phase change heat storage chamber 41 is evenly distributed A plurality of phase-change thermal storage elements 5 described in Embodiment 1 are installed, the lower end of the housing 1 of the phase-change thermal storage element 5 is fixed on the partition plate 82, and the upper end of the housing 1 is fixed on the top of the phase-change thermal storage chamber 41. On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com