Novel slab type spiral heat exchanger

A heat exchanger, a plate-type technology, applied in the field of new-type plate-type spiral heat exchangers, can solve the problems of complex design, low heat exchange efficiency of heat exchangers, increase of heat exchange area, etc., to enhance water convection and turbulence, reduce Scale formation, effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

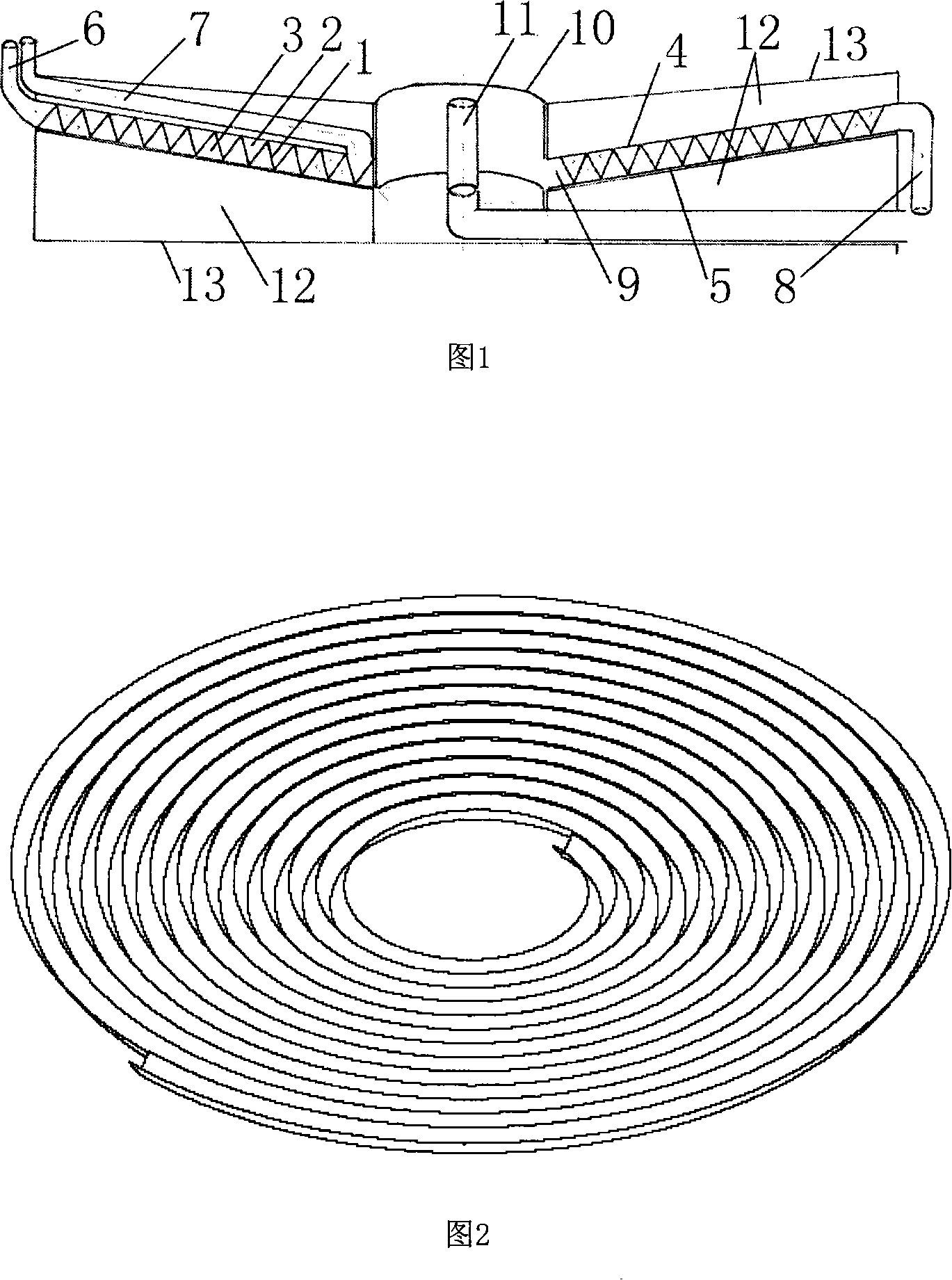

[0021] The heat exchanger of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] As shown in Figure 1, the core part of the heat exchanger designed in this embodiment is a piece of high thermal conductivity metal sheet made by stamping, forming a spiral groove from the inside to the outside (actually in the metal A metal plate 1 with spiral grooves is formed on both sides of the thin plate with grooves alternated between concavo-convex; by covering the metal plate 1 with the spiral grooves on the metal plate 4, the plastic plate 5 and the thermal insulation material (in the figure) Not shown), form mutually isolated upper layer helical fluid channel 2 and lower layer helical fluid channel 3 on both sides of the metal plate 1 of this band helical groove; The cold water inlet 6 at the edge of 2 flows in, and flows out through the clean water outlet 7 in the middle after being preheated, while the bathing waste w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com