Cyclone burner for high-temperature air burning industrial furnace

A technology for high-temperature air and industrial furnaces, applied in gas fuel burners, burners, combustion methods, etc., can solve the problem of low gas temperature distribution in the furnace and achieve low local high temperature, lower emissions, and uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

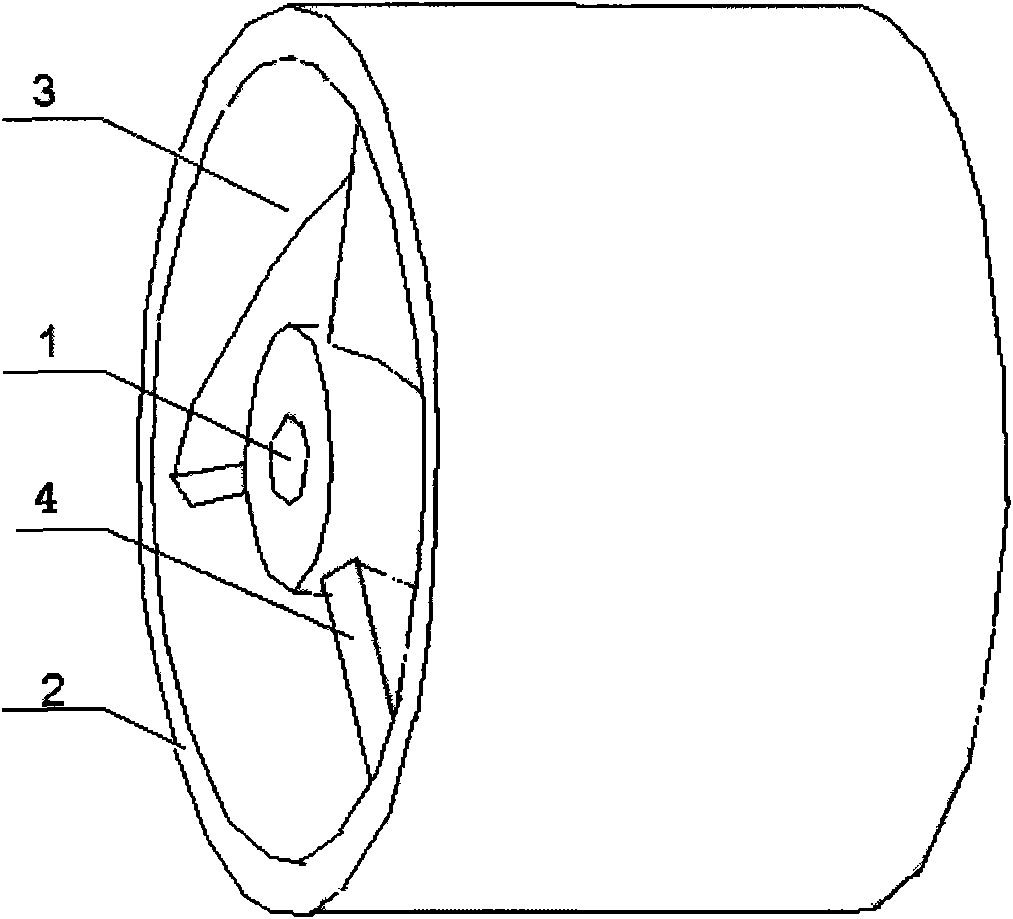

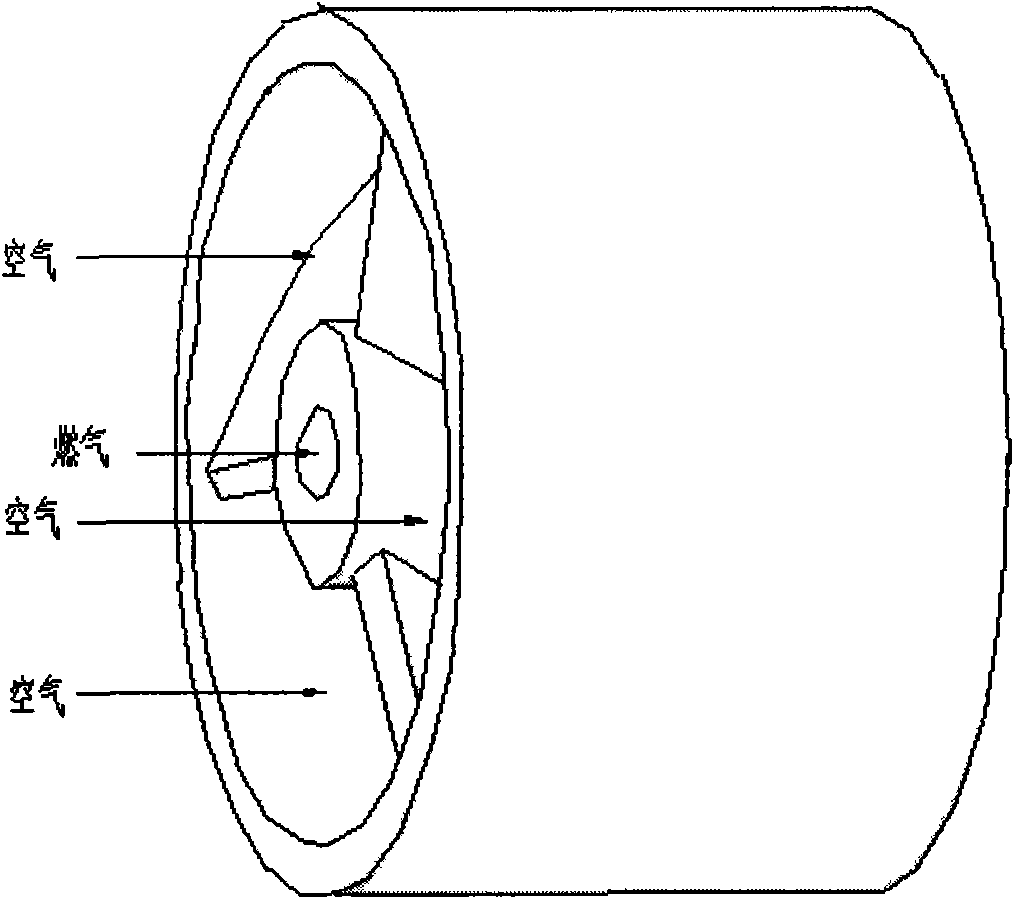

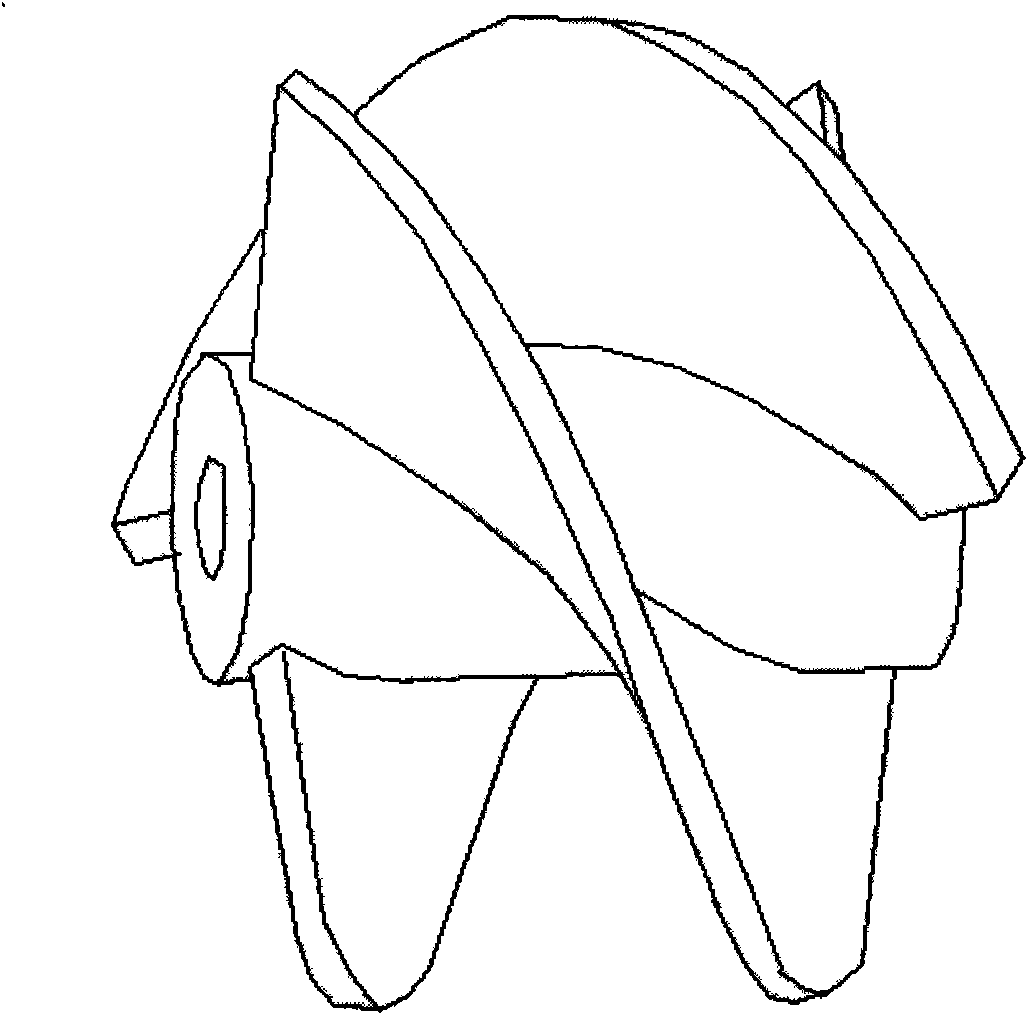

[0021] The concentric axial swirling burner is composed of a central circular straight-through pipe 1, an outer casing 2, a rotating channel 3, and spiral fins 4. The central circular straight-through pipe 1 is located coaxially inside the outer casing 2. The rotation angle of the high-temperature air inlet and outlet of the rotating channel 3 varies from 0 degrees to 360 degrees. The rotating channel 3 consists of three spiral fins 4 axially according to the spiral angle of 0° to 360° and the dimensionless spiral extension length R=2 (R=l / h, l is the axial length of the spiral fins, h is The height of the spiral fin) is rotated and arranged between the central circular straight-through pipe 1 and the outer casing 2.

[0022] Under the following conditions: the fuel is city natural gas, the fuel gas jet velocity of the central circular tube is 29.5m / s; the jet velocity of the air rotating channel is 35.6m / s. The preheated air is 1273K, the excess air coefficient is 1.2, the o...

Embodiment 2

[0028] On the basis of Embodiment 1, when the swirl angle of the air swirling channel is θ=180°, the inlet parameters are respectively: the fuel is urban natural gas, the fuel gas jet velocity of the central circular tube is 29.5m / s; the jet velocity of the air swirling channel is 35.6m / s. The preheated air is 1273K, the excess air coefficient is 1.2, the oxygen concentration in the air is 8%, the heat dissipation at the bottom of the furnace is a constant heat flux density, and the size is 28580W / m 2 , the speed ratio of fuel and air is a=1.09. The distribution results of the nitrogen oxide emission concentration at the outlet of the burner with the spiral extension factor obtained by numerical calculation, such as Figure 5 shown.

Embodiment 3

[0030] On the basis of Embodiments 1 and 2, keep the helix angle of the burner fins at θ=180°, the stretching length factor of the fins R=2, and the inlet parameters are respectively: the fuel is urban natural gas, and the fuel gas jet flow of the central circular tube The velocity is 29.5m / s; the jet velocity of the air rotating channel is 35.6m / s. The preheated air is 1273K, the excess air coefficient is 1.2, the oxygen concentration in the air is 8%, the heat dissipation at the bottom of the furnace is a constant heat flux density, and the size is 28580W / m 2 . The distribution results of the nitrogen oxide emission concentration at the outlet of the burner with the velocity ratio of fuel and air obtained by numerical calculation, such as Figure 6 shown.

[0031] It can be seen from the comparison that the NOX emission of the swirl burner is lower than that of the once-through burner under the same conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com