Semiconductor light source bar cooling system and cooling method in aging tests

A technology of cooling system and aging test, which is applied in the cooling/heating device of the lighting device, the functional test of the magnetic head, the lighting device, etc., which can solve the problems of uneven temperature, reduced energy conversion efficiency, and affecting the performance of the HAMR head, etc., to achieve good results. Thermal stability, achieving temperature uniformity, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

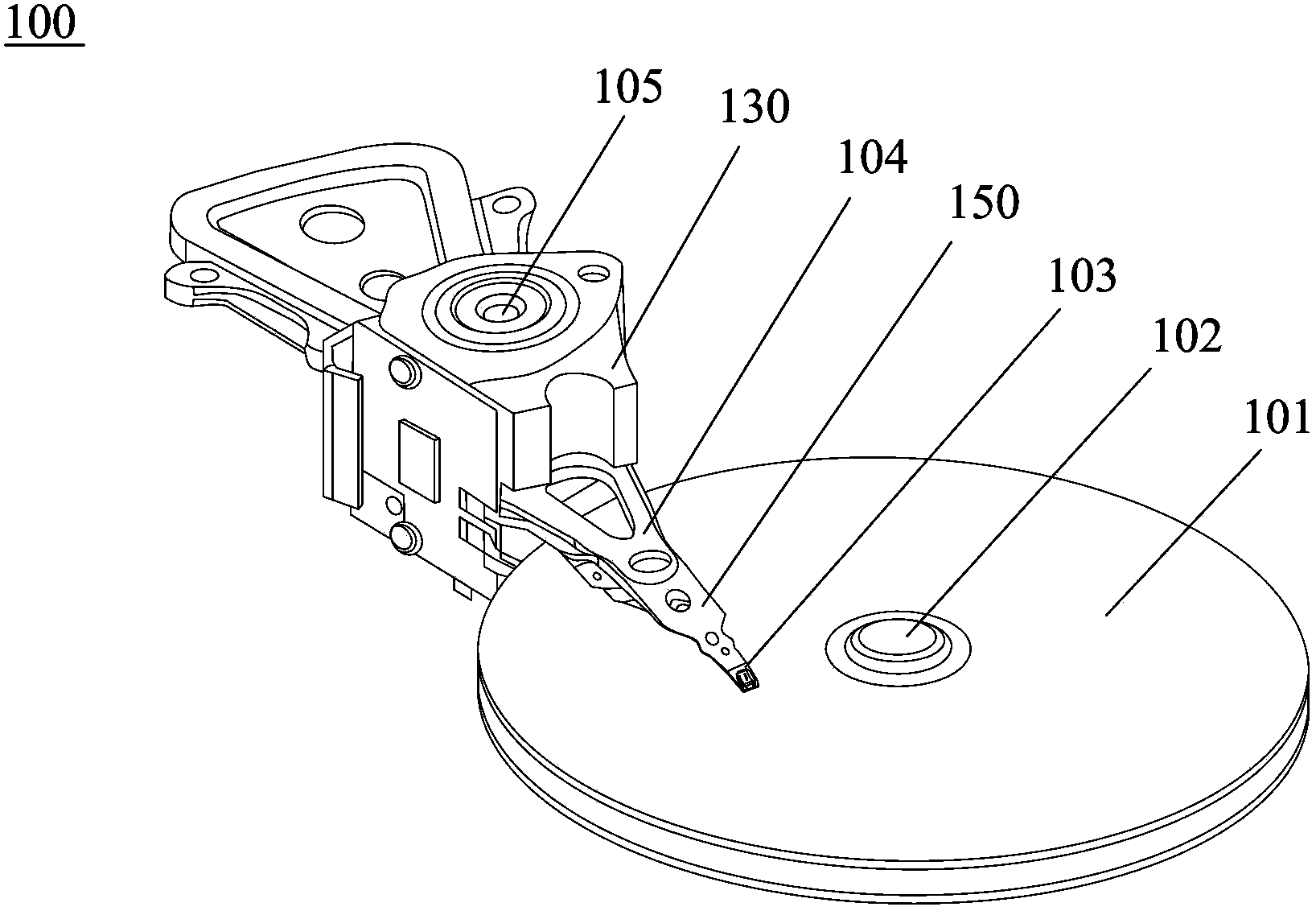

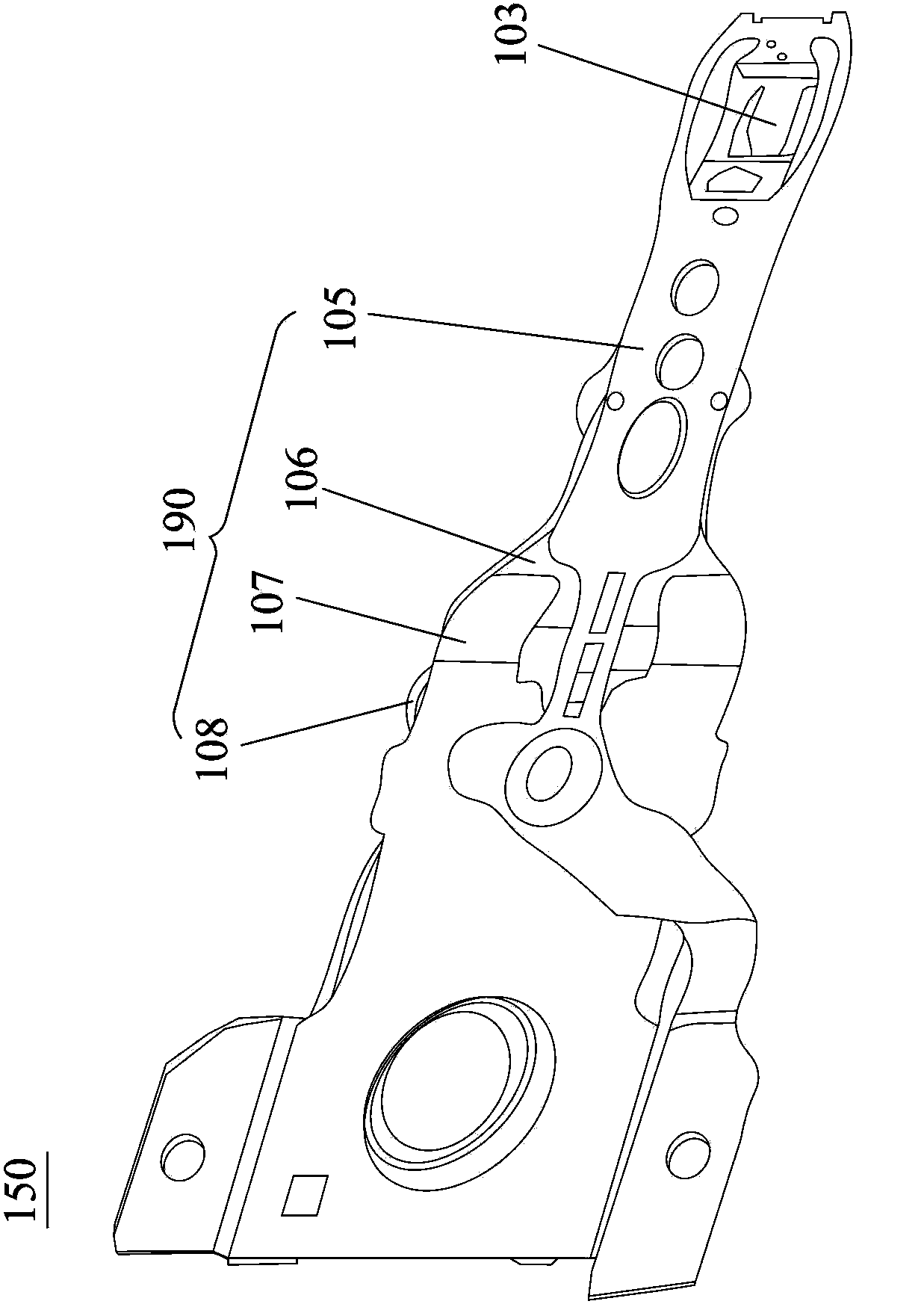

[0032] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. As mentioned above, the essence of the present invention lies in a cooling system and cooling method for a semiconductor light source bar during the aging test, which can dissipate the heat generated by the semiconductor light source bar during the aging test and make its local temperature uniform, Thereby maintaining the temperature required for burn-in tests and improving the thermal stability of the HAMR head.

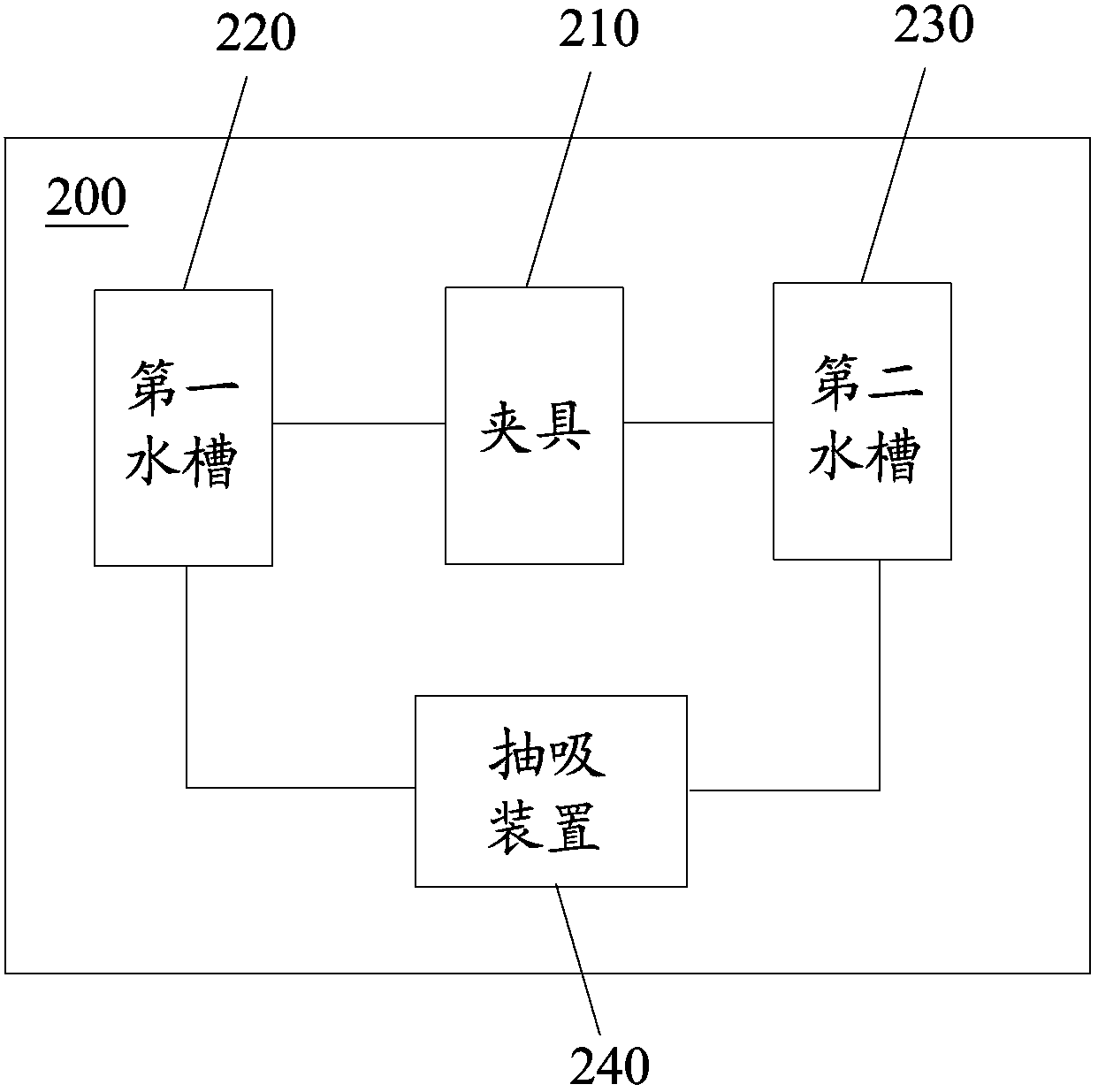

[0033] Figure 2a The first embodiment of the cooling system of the semiconductor light source bar in the aging test of the present invention is shown. As shown in the figure, the cooling system 200 includes a semiconductor light source bar 201 (such as image 3 shown), the first water tank 220 containing the cooling liquid and connected to the clamp 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com