Aerogel heat insulating device for electronic product

A technology for heat insulation devices and electronic products, applied in adhesives, cooling/ventilation/heating transformation, film/sheet adhesives, etc., can solve the problems of reduced heat insulation function, shortened life, and non-formability, etc., to reduce local High temperature, reduced temperature difference, easy die-cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

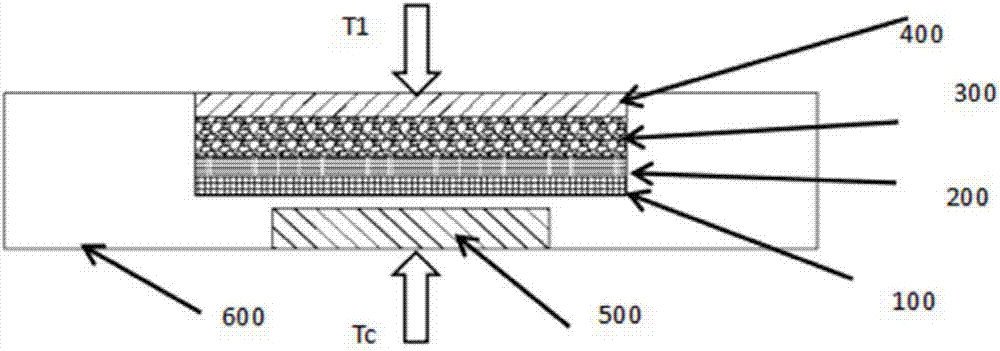

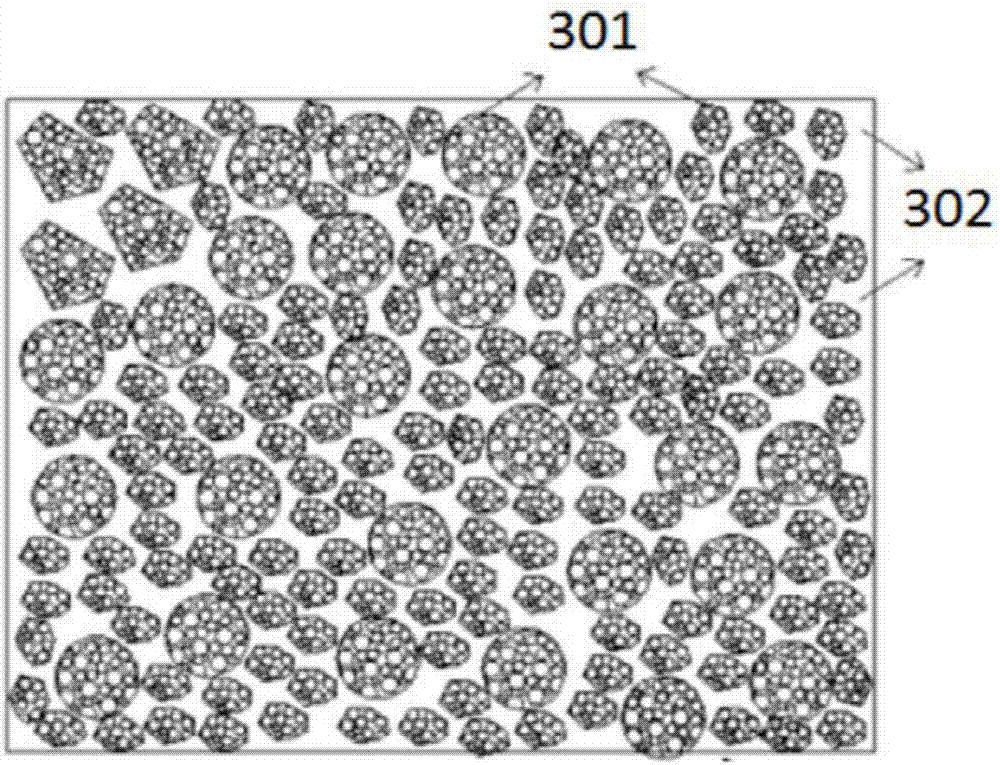

[0020] Such as figure 1 and image 3 As shown, the present embodiment provides an airgel thermal insulation device for electronic products, which includes a graphite sheet 200 and an airgel sheet 300 positioned on the graphite sheet 200; the airgel sheet The upper surface of the layer 300 is provided with an adhesive layer 400; the lower surface of the graphite sheet 200 is provided with a polymer insulating protective layer 100; the total thickness of the airgel heat insulation device is 0.2mm; the graphite sheet 200 is an artificial graphite sheet with a thickness of 0.025 mm; the airgel sheet 300 is composed of a plurality of SiO2 airgel small particles (particle diameter is 2-5 μm), and the gap is filled with vinyl polydimethylsiloxane Oxyalkylene adhesive 302 (viscosity range is 500-800cps), and its thickness is 0.125mm; Described adhesive layer 400 is PET double-sided adhesive tape, and its thickness is 0.03mm; Described macromolecular polymer insulating protective laye...

Embodiment 2

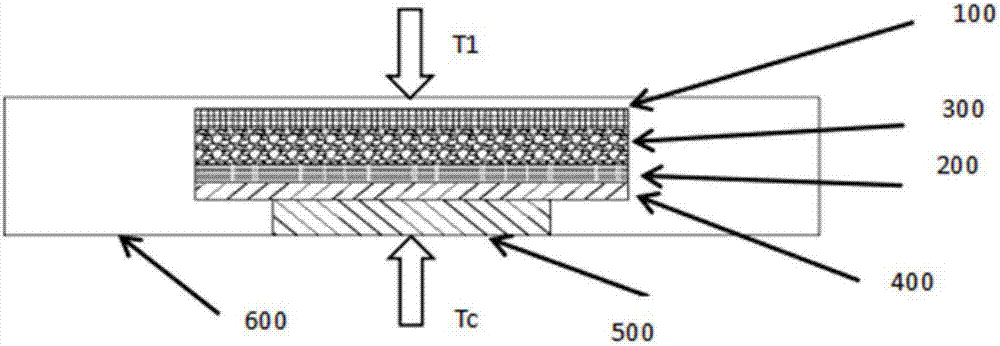

[0023] Such as figure 2 and image 3 As shown, the present embodiment provides an airgel thermal insulation device for electronic products, which includes a graphite sheet 200 and an airgel sheet 300 positioned on the graphite sheet 200; the airgel sheet The upper surface of the layer 300 is provided with a polymer insulating protective layer 100; the lower surface of the graphite sheet 200 is provided with an adhesive layer 400; the total thickness of the airgel heat insulation device is 0.2 mm; the graphite sheet 200 is provided with an adhesive layer 400; 200 is an artificial graphite sheet with a thickness of 0.025 mm; the airgel sheet 300 is composed of a plurality of SiO2 airgel small particles (particle diameter is 2-5 μm), and the gap is filled with vinyl polydimethylsiloxane Oxyalkylene adhesive 302 (viscosity range is 500-800cps), and its thickness is 0.125mm; Described adhesive layer 400 is PET double-sided adhesive tape, and its thickness is 0.03mm; Described mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com