Laser preparation device and method of metal matrix carbon nanometer composite material

A composite material and a preparation device technology, which is applied in the field of laser preparation devices for metal-based carbon nanocomposite materials, can solve the problem that it is difficult to meet the requirements of product shape individuation, complexity and diversification, poor electrical, thermal, mechanical and other properties of composite materials, etc. Affecting the enhancement effect of carbon nanotubes, etc., to achieve the effect of short cycle, good performance and personalized shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

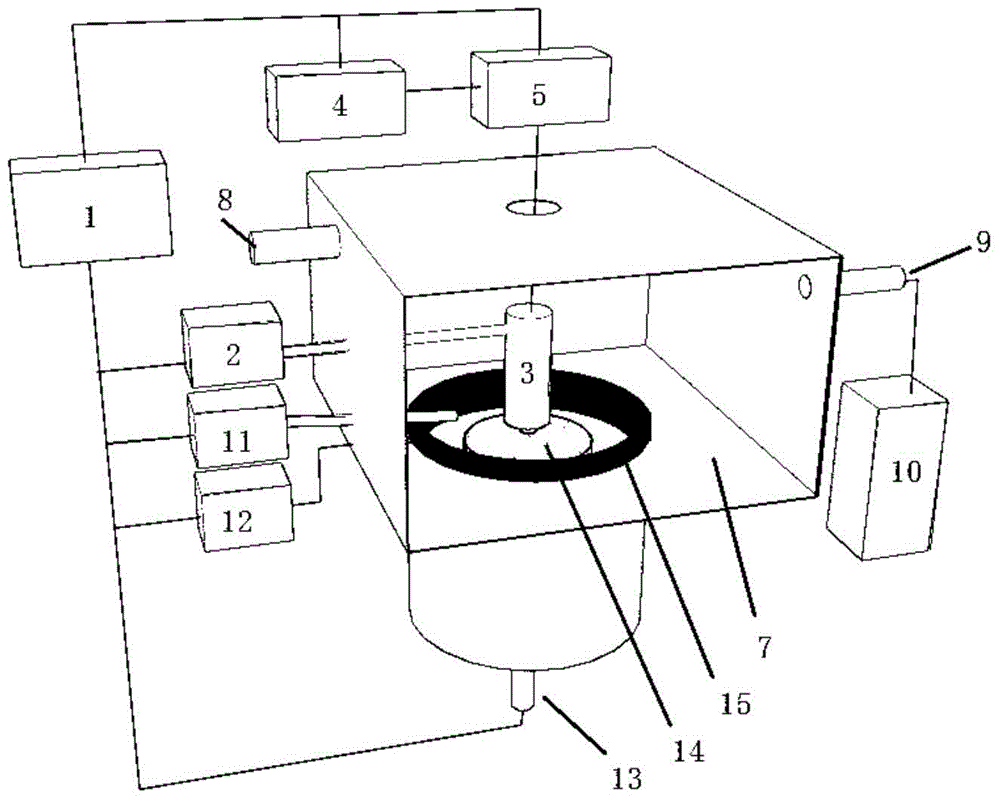

[0030] Such as figure 1 As shown, a laser preparation device for metal-based carbon nanocomposites includes a numerical control system 1, a vacuum forming chamber 7 and a lifting system 13, and a working head 3 and a substrate 14 are arranged in the vacuum forming chamber 7; A powder feeder 2, a carbon source gas generator 11, a laser 4, and a laser transmission device 5 are arranged outside the room 7; the powder feeder 2 controls the working head 3 to lay metal powder on the substrate 14; the laser 4 emits laser light The metal powder is sintered by the beam through the laser transmission device 5; the carbon source gas generator 11 is used to feed the carbon source gas when the metal powder is sintered by the laser beam; the lifting system 13 is used to control the rise of the substrate 14 or descending; the numerical control system 1 is respectively connected with the laser 4, the powder feeder 2 and the carbon source gas generator 11.

[0031] In the device of the presen...

Embodiment 2

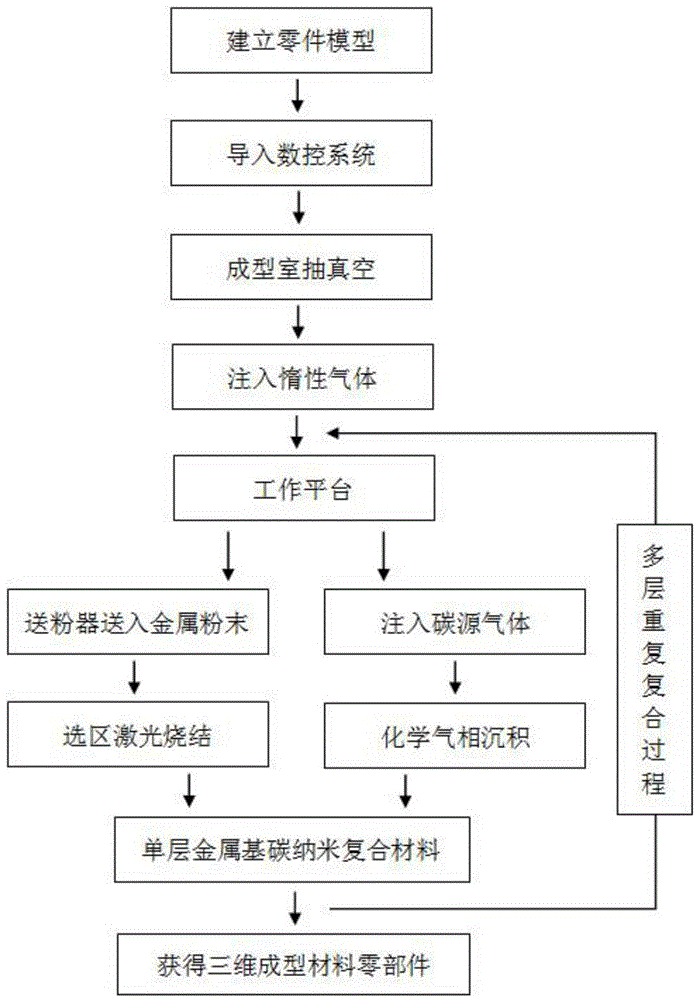

[0037] figure 2 A flowchart showing a laser preparation method of a metal-based carbon nanocomposite;

[0038] A laser preparation method of a metal-based carbon nanocomposite material, specifically comprising the following steps:

[0039] Step (1). Establish the three-dimensional model of the parts, and carry out hierarchical discretization, generate scanning path data, and import the data into the numerical control system;

[0040] Step (2). First evacuate the vacuum forming chamber, then inject inert gas into the vacuum forming chamber, and control the oxygen concentration in the forming chamber within a certain concentration range;

[0041] Step (3). The powder feeder sends the metal powder into the vacuum forming chamber, lays a layer of metal powder on the substrate, and recycles the excess metal powder at the same time;

[0042] Step (4). According to the preset graphic data, the laser beam scans the metal powder to form a focused spot on the processing plane of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com