Method for preparing fluorinating reagent and fluoride continuously by microchannel reactor

A technology of microchannel reactors and fluorinated reagents, applied in the preparation of amino compounds by condensation/addition reactions, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of fluorinated reagents and fluorides, energy consumption and Problems such as high environmental protection cost and low production efficiency achieve the effect of low production cost, shortened production cycle and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 Ishikawa reagent

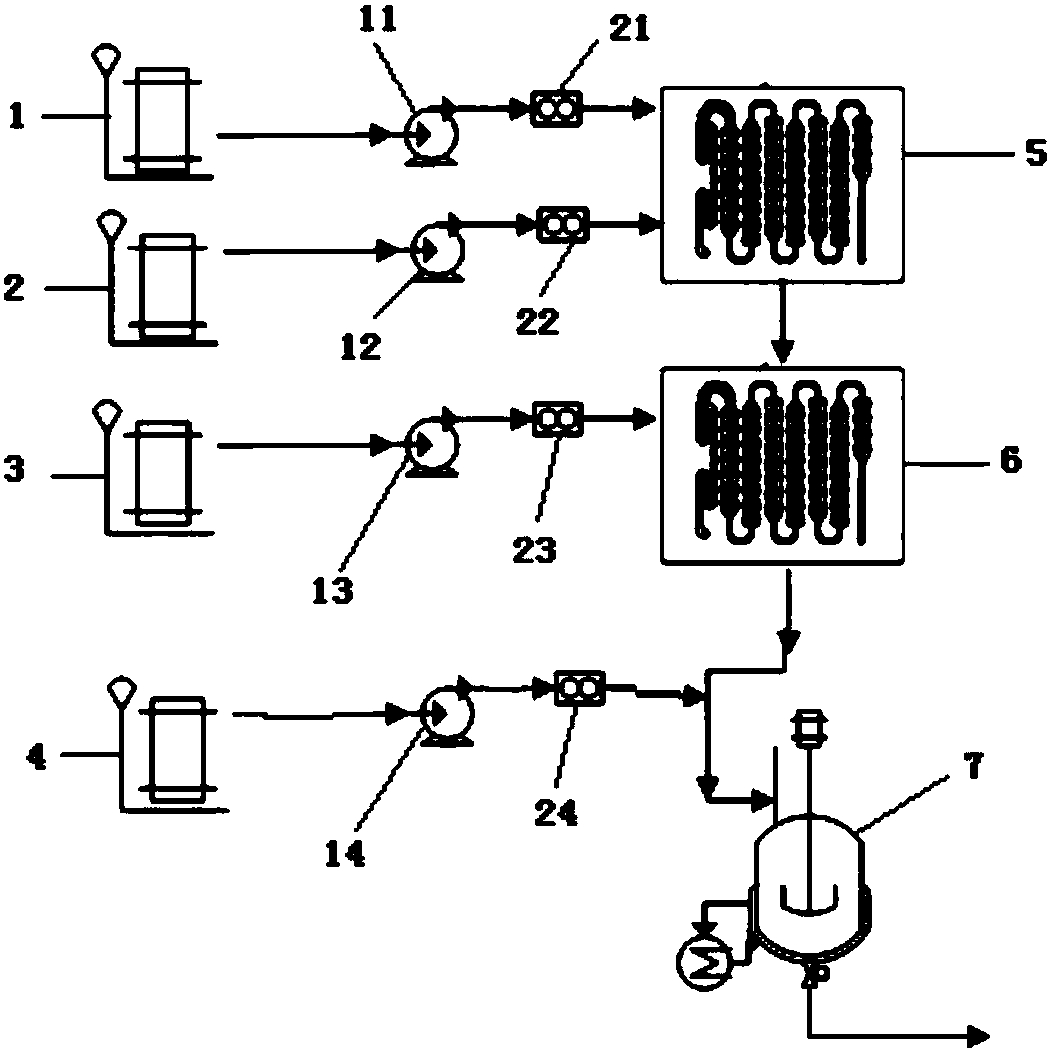

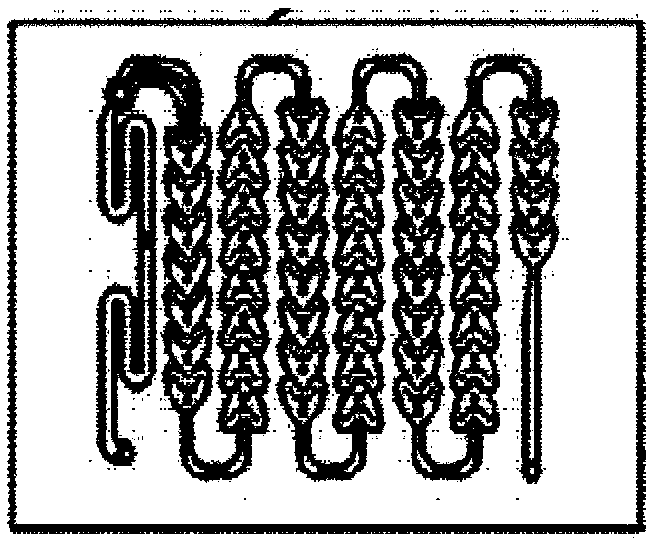

[0044] The device used: high-throughput microchannel reactor, refer to Figure 4 Microchannel reactor continuous flow synthesis process flow diagram.

[0045] The diethylamine solution that needs to enter the microchannel reactor is prepared in advance, the flow rate ratio of the relevant materials is preset through the flow meter, the speed of the feed pump is adjusted, and the ratio of the materials is kept within a certain range. Among them, diethylamine: The mass ratio of dichloromethane is 1:1, that is, 200g diethylamine (2.74mol, 1.0eq) and 200g dichloromethane are formulated into a solution, and diethylamine solution and 411g hexafluoropropylene (2.74mol, 1.0eq) are respectively It is introduced into functional module a through a feeding pump, the reaction temperature is set at 20°C, and the reaction residence time is 90 seconds. The collected liquid flowing out of functional module A is the Ishikawa reagent, an...

Embodiment 2

[0046] The preparation of embodiment 2 Yarowenko reagent

[0047] The device used: high-throughput microchannel reactor, refer to Figure 4 Microchannel reactor continuous flow synthesis process flow diagram.

[0048] The diethylamine solution that needs to enter the microchannel reactor is prepared in advance, and the flow rate ratio of relevant materials is preset by a flowmeter, wherein diethylamine: the mass ratio of dichloromethane is 1:0.8, that is, 200g diethylamine ( 2.74mol, 1.0eq) and 160g of dichloromethane are prepared into a solution, and the diethylamine solution and 319g of chlorotrifluoroethylene (2.74mol, 1.0eq) are respectively introduced into functional module a through a feed pump, and the reaction temperature is set at 20°C , the reaction residence time is 90 seconds, and the liquid flowing out from the functional module a is collected as the Yarowenko reagent, and the reaction is a quantitative reaction.

Embodiment 3

[0049] The preparation of embodiment 3 TFEDMA reagent

[0050] The device used: high-throughput microchannel reactor, refer to Figure 4 Microchannel reactor continuous flow synthesis process flow diagram.

[0051] The diethylamine solution that needs to enter the microchannel reactor is prepared in advance, and the flow rate ratio of the relevant materials is preset by the flow meter, wherein diethylamine: the mass ratio of dichloromethane is 1:0.9, that is, 200g diethylamine ( 2.74mol, 1.0eq) and 180g of dichloromethane are prepared into a solution, and the diethylamine solution and 274g of tetrafluoroethylene (2.74mol, 1.0eq) are respectively introduced into the functional module a through the feeding pump, and the reaction temperature is set at 20°C. The reaction residence time is 95 seconds, and the liquid flowing out from the functional module a is collected as the Yarowenko reagent, and the reaction is a quantitative reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com