Hydrogenation process for silicon tetrachloride and process for preparing high-purity silicon from trichlorosilane

A technology for silicon tetrachloride and trichlorosilane, which is applied in the fields of halogenated silicon compounds, chemical instruments and methods, silicon, etc., can solve the problems of poor processing ability of silicon tetrachloride, low conversion rate, pollution of the environment, etc. The effect of incomplete reaction, improved reaction speed, and complete contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

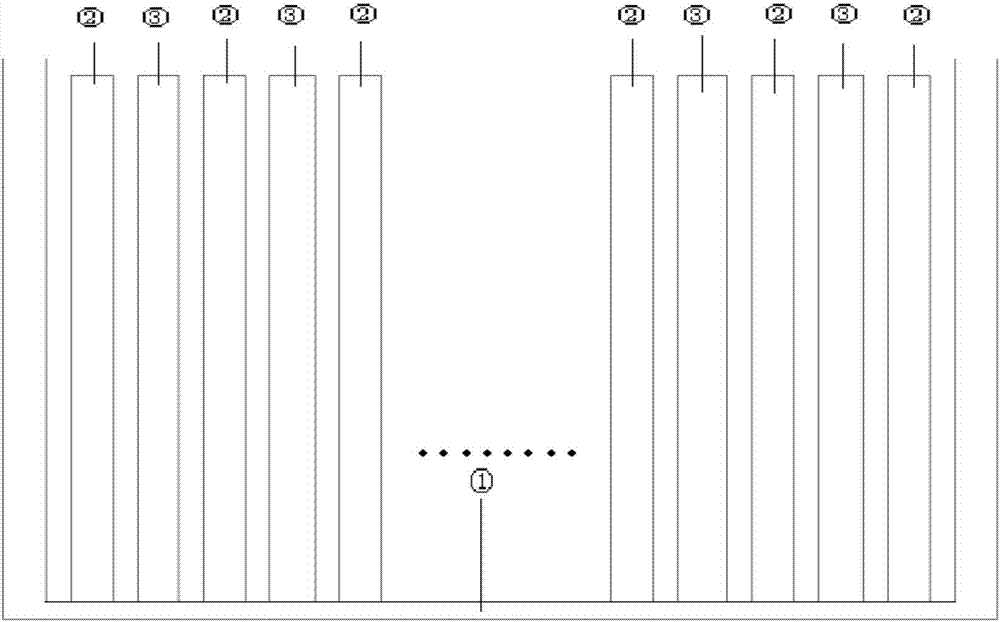

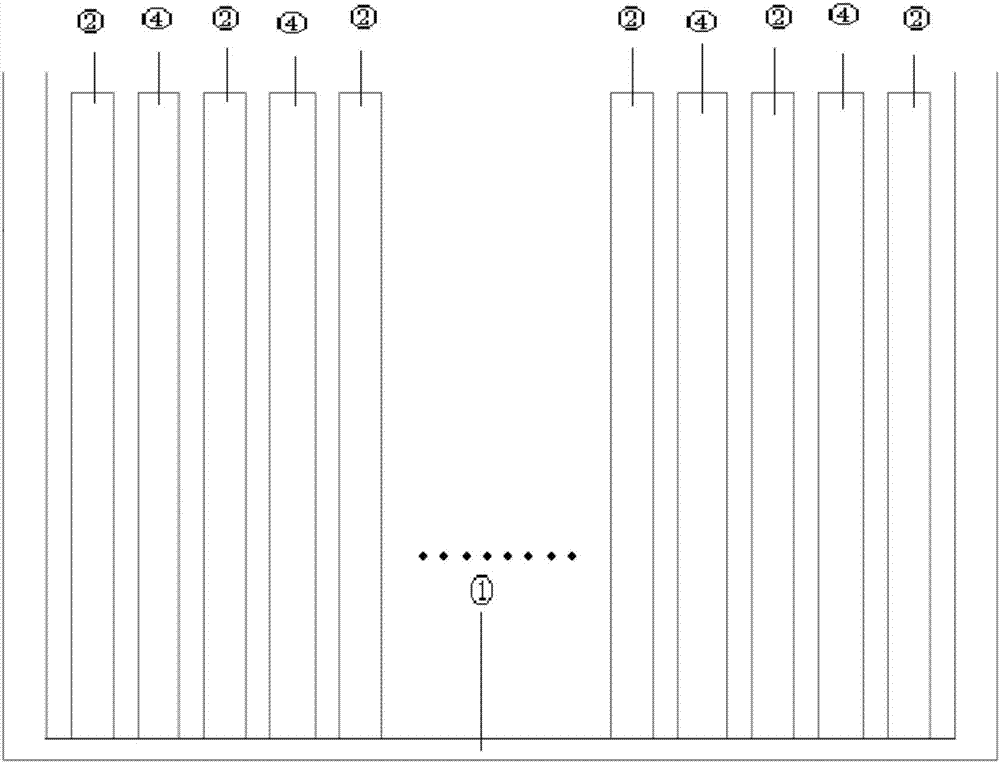

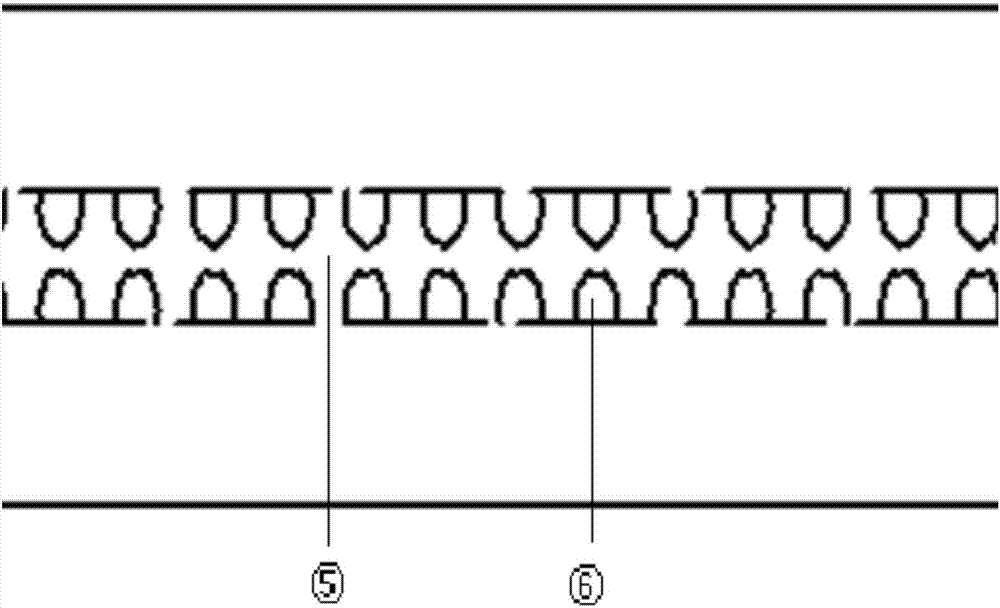

[0073] (1) Put silicon tetrachloride gas and hydrogen gas into the microchannel mixing heater at a molar ratio of 0.2:1 to heat and mix them. The heating temperature is 700°C to obtain a heated mixed gas. The microchannel hybrid heater is placed in an electric heating device; wherein, the heating device is provided with insulation facilities and automatic temperature control facilities. The microchannel mixing heater includes several microchannel mixer units and several heating devices, and the microchannel mixer units and heating devices are arranged at intervals, such as figure 1 Shown; The microchannel mixer unit includes 10 microchannel mixer substrates to ensure rapid heat transfer; the microchannel mixer substrate includes no less than 1 microchannel; the width of the microchannel is 500 microns, and the depth For 300 µm, the upper and lower parts of the microchannel are preferably made as image 3 As shown, the surface area can be increased to improve mixing efficiency...

Embodiment 2

[0079] (1) Put silicon tetrachloride gas and hydrogen gas into the microchannel mixing heater at a molar ratio of 0.5:1 to heat and mix them. The heating temperature is 100°C to obtain a heated mixed gas. The microchannel hybrid heater is placed in an electric heating device; wherein, the heating device is provided with insulation facilities and automatic temperature control facilities. The microchannel mixing heater includes several microchannel mixer units and several heating devices, and the microchannel mixer units and heating devices are arranged at intervals, such as figure 1 Shown; The microchannel mixer unit includes 100 microchannel mixer substrates to ensure rapid heat transfer; the microchannel mixer substrate includes no less than 1 microchannel; the width of the microchannel is 10 microns, and the depth For 10 µm, the upper and lower parts of the microchannel are preferably made as image 3 As shown, the surface area can be increased to improve mixing efficiency ...

Embodiment 3

[0086](1) Put silicon tetrachloride gas and hydrogen gas into the microchannel mixing heater at a molar ratio of 1:3 to heat and mix them. The heating temperature is 600°C to obtain a heated mixed gas. The microchannel hybrid heater is placed in an electric heating device; wherein, the heating device is provided with insulation facilities and automatic temperature control facilities. The microchannel mixing heater includes several microchannel mixer units and several heating devices, and the microchannel mixer units and heating devices are arranged at intervals, such as figure 1 Shown; The microchannel mixer unit includes 20 microchannel mixer substrates to ensure rapid heat transfer; the microchannel mixer substrate includes no less than 1 microchannel; the width of the microchannel is 200 microns, and the depth For 100 µm, the upper and lower parts of the microchannel are preferably made as image 3 As shown, the surface area can be increased to improve mixing efficiency an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com