High-temperature emulsifier applied to oil-based drilling fluids and preparation method of high-temperature emulsifier

An oil-based drilling fluid, high-temperature emulsification technology, applied in the field of petroleum drilling fluids, can solve the problems of increasing on-site operation of the main emulsifier and auxiliary emulsifier, increasing the production process and product cost, and detrimental to the stability of the drilling fluid system. and application, reducing production cost, and the effect of strong industrial operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

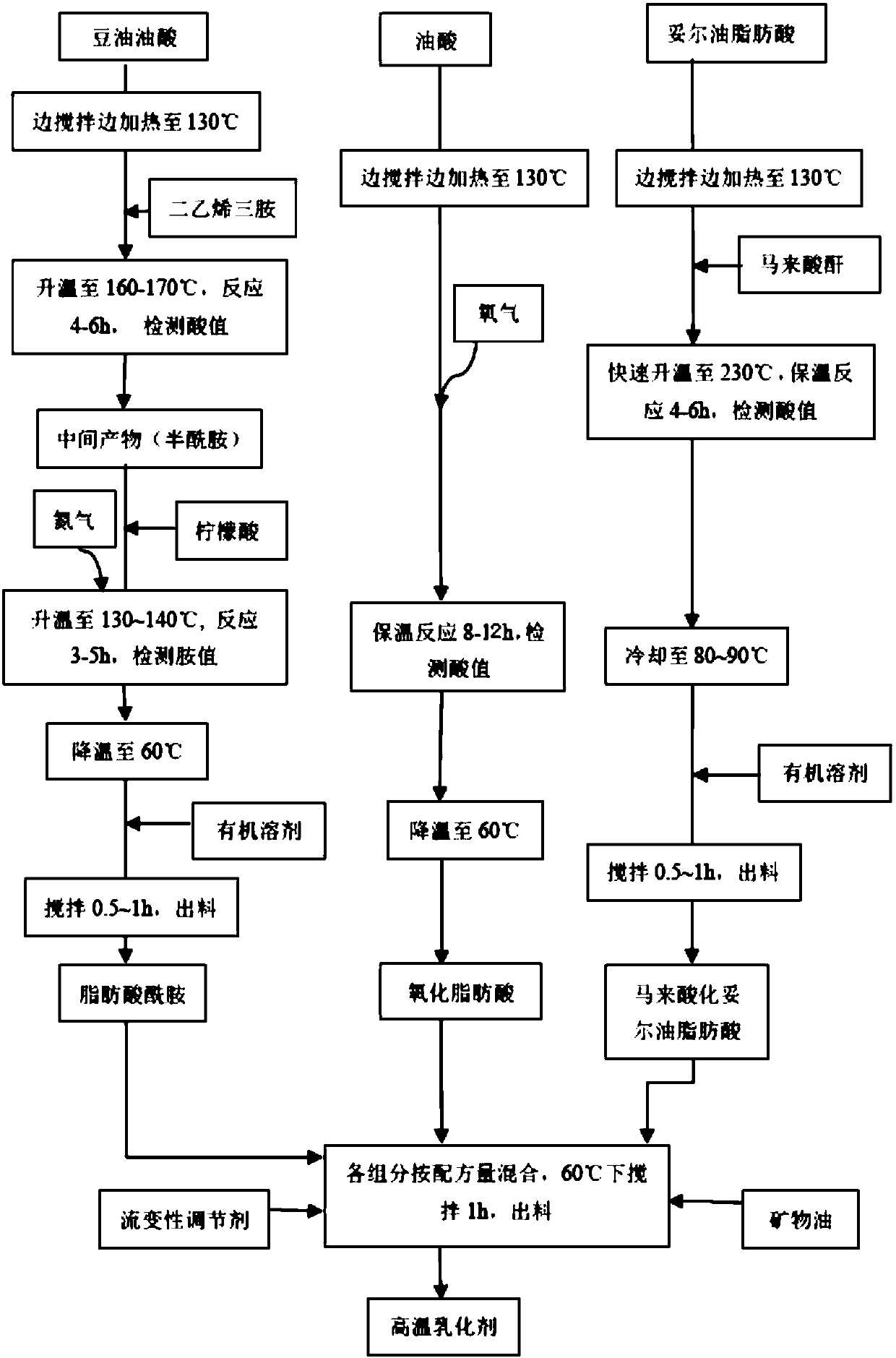

[0036] Such as figure 1 Shown, be a kind of preparation method of the high-temperature emulsifier that is applied to oil-based drilling fluid of the present invention, it comprises the following steps:

[0037] A. Preparation of fatty acid amides: Add the fatty acid in the formula amount into the reaction kettle, and heat it to 120-180°C while stirring; add polyethylene polyamine into the reaction kettle, and raise the temperature in the reaction kettle to 150-190°C , react for 4 to 6 hours, measure the acid value of the material every 1 hour during the reaction until the acid value is <10mgKOH / g; cool the temperature of the material to 90 to 120°C, add citric acid and raise the temperature of the reactor to 130 to 140°C, ventilate for 3~5h, measure the amine value of the material every 1h during the reaction, until the amine value<12mgKOH / g; cool the temperature of the material to 50~80°C, add an organic solvent, react for 0.5~1h, and produce Fatty acid amides are obtained;

...

Embodiment 1

[0046] Embodiment 1: the preparation of high temperature emulsifier

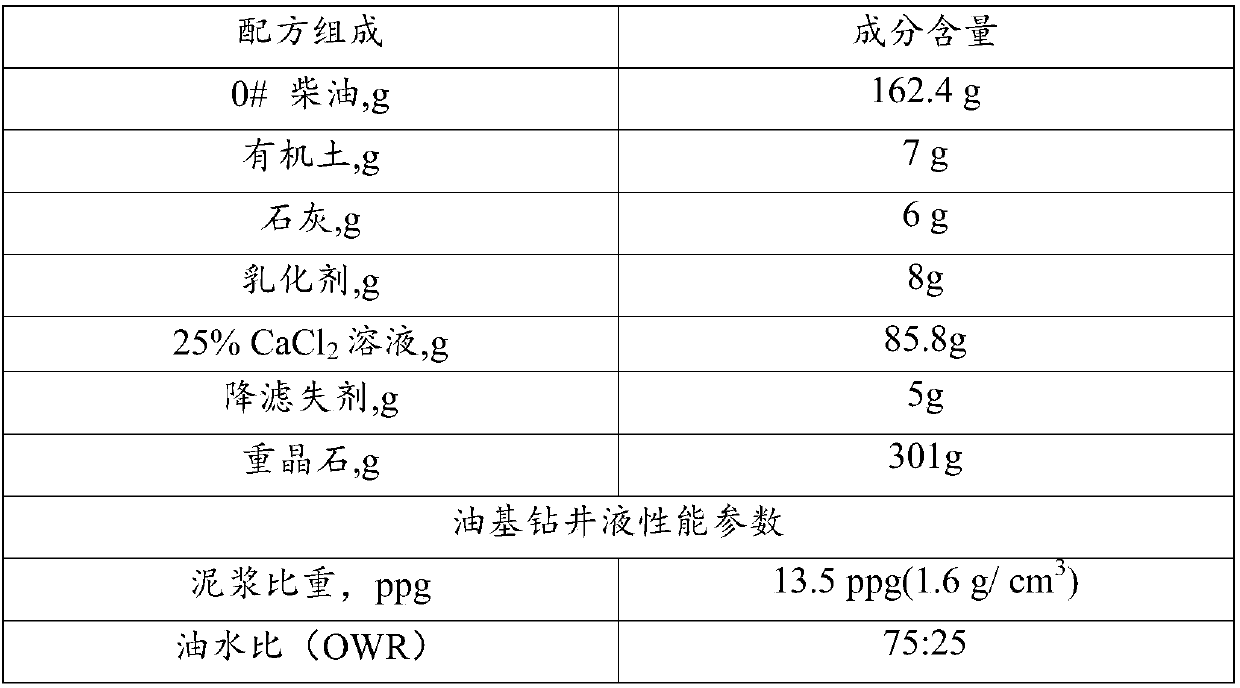

[0047] A high-temperature emulsifier applied to oil-based drilling fluid. Based on the sum of the mass percentages of the high-temperature emulsifier being 100%, the composition of the high-temperature emulsifier includes: 30% of fatty acid amide, 35% of oxidized fatty acid, and maleic acid Oil fatty acid 15%, dimer acid 5%, 5# white oil 15%.

[0048] Such as figure 1 Shown, the preparation method of this high temperature emulsifier comprises the following steps:

[0049] A, the preparation of fatty acid amides:

[0050] to 10m 3 Add 3.6t of soybean oil oleic acid to the reactor, start stirring, heat with heat transfer oil, and heat the oleic acid to 130°C while stirring; use a flow pump to add 0.72t of diethylenetriamine to the reactor, and then The temperature device raises the temperature in the reactor to 160-170°C, and the reaction time is 4-6 hours. During the reaction, samples are taken every 1 ho...

Embodiment 2

[0056] Embodiment 2: the preparation of high temperature emulsifier

[0057] A high-temperature emulsifier applied to oil-based drilling fluid. Based on the sum of the mass percentages of the high-temperature emulsifier being 100%, the composition of the high-temperature emulsifier includes: 20% of fatty acid amide, 45% of oxidized fatty acid, and maleic acid Oil fatty acid 20%, trimer acid 5%, 3# white oil 10%.

[0058] In this embodiment, the fatty acid amide is prepared according to the following steps: react tallow oleic acid with triethylenetetramine at a mass ratio of 4.5:1, and after the reaction, add tallow oleic acid at a mass ratio of 4:1 to citric acid Citric acid is reacted, and the final product obtained is mixed with ethylene glycol at a mass ratio of 10:1 to obtain final product. Oxidized fatty acid is a reaction product obtained by reacting linoleic acid with air; maleated tall oil fatty acid is a product obtained by reacting tall oil fatty acid and maleic anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com