Method for continuous industrial production of coal gas by multi-chamber microwave heating

The technology of microwave heating and microwave heating device is applied in the field of continuous industrial gas production, which can solve the problems of high gas purification cost, complex production equipment and high raw material requirements, and achieves controllable gas composition, pure gas, and elimination of purification process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

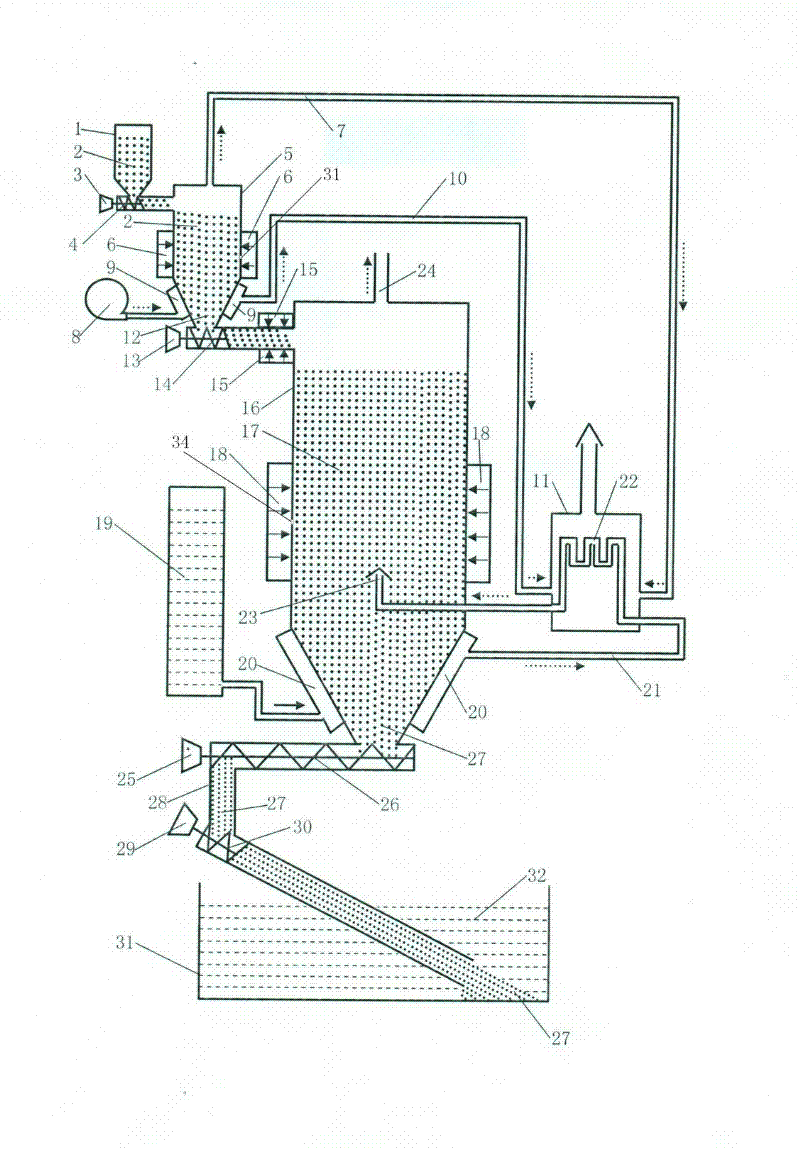

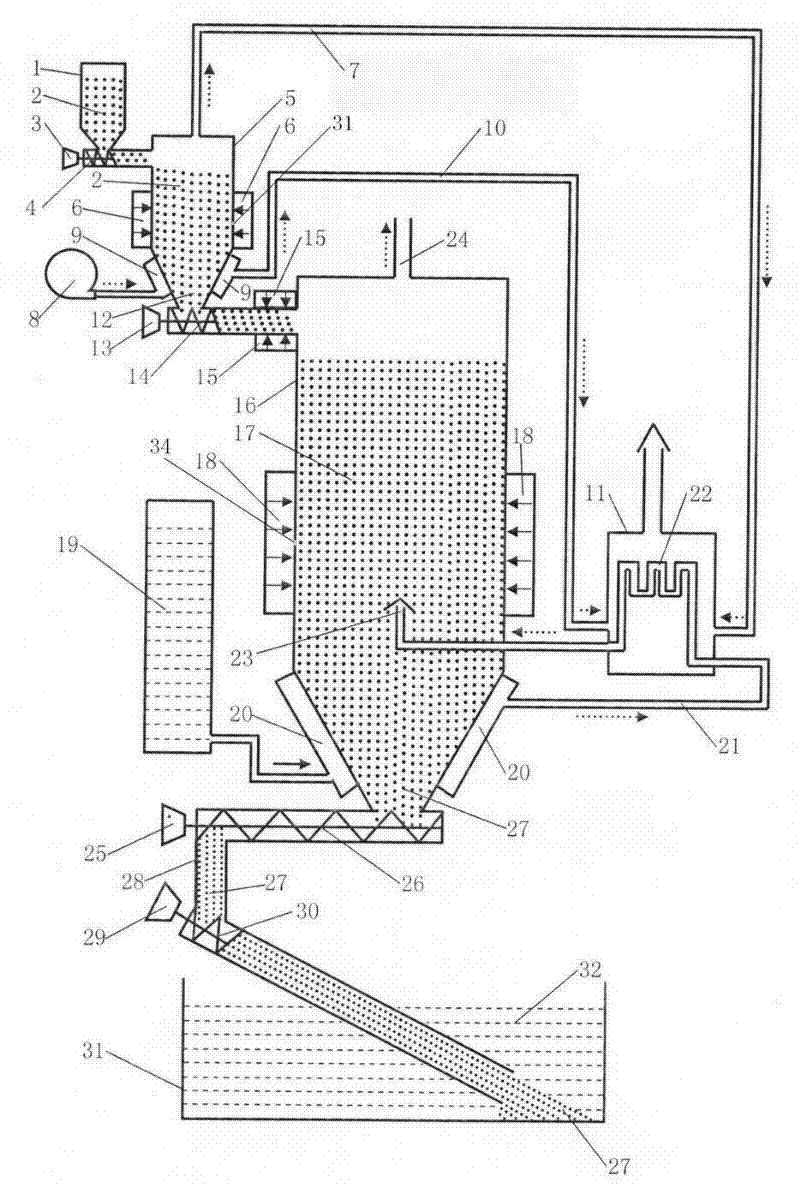

[0048] See figure 1 , 1 is the pulverized coal silo, which contains pulverized coal 2 mixed with desulfurization agent, adjust the speed of the frequency conversion speed regulation motor 3 to 600 rpm and drive the raw material screw pushing device 4 to rotate to push the pulverized coal 2 into the pulverized coal pyrolysis Bin 5; Microwave heating device 6 injects microwaves into coal powder pyrolysis bin 5. By adjusting the power of microwave heating device 6 to 4KW and controlling the maximum heating temperature to 480°C, pulverized coal 2 can be quickly and uniformly heated by absorbing microwaves. Pyrolysis produces CO, CH 4 and gasification tar, etc., the pyrolysis gas rises into the pyrolysis gas collection pipeline 7 and finally enters the steam secondary heating device 11 to participate in the combustion reaction; the high-pressure fan 8 supplies cold air to the air preheating device 9, Heat exchange is carried out through the warehouse wall, and the cold air cools t...

Embodiment 2

[0050] Such as figure 1 As shown, 1 is the pulverized coal silo, which contains pulverized coal 2 mixed with desulfurizer, adjust the speed of the frequency conversion speed regulating motor 3 to 800 rpm and drive the raw material screw pushing device 4 to rotate to push the pulverized coal 2 into the pulverized coal Pyrolysis bin 5; microwave heating device 6 injects microwaves into coal powder pyrolysis bin 5, by adjusting the power of microwave heating device 6 to 6KW, controlling the maximum heating temperature to 470°C, the microwave energy absorbed by pulverized coal 2 can be quickly and evenly Heating, pyrolyzing CO, CH 4 and gasification tar, etc., the pyrolysis gas rises into the pyrolysis gas collection pipeline 7 and finally enters the steam secondary heating device 11 to participate in the combustion reaction; the high-pressure fan 8 supplies cold air to the air preheating device 9, Heat exchange is carried out through the warehouse wall, and the cold air cools th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com