Method for preparing active carbon by using coke reactivity testing device

A technology for preparing activated carbon and measuring devices, which is applied in the field of preparing activated carbon, can solve the problems of weak adsorption capacity and low specific surface area, and achieve the effects of simple steps, accelerated reaction rate, and precise control of heating rate and reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

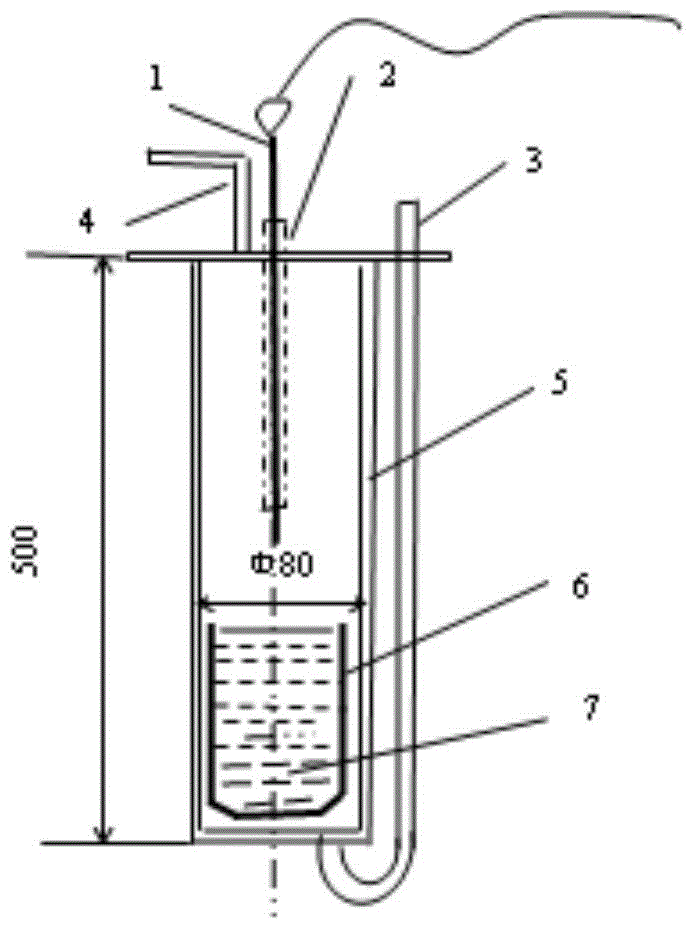

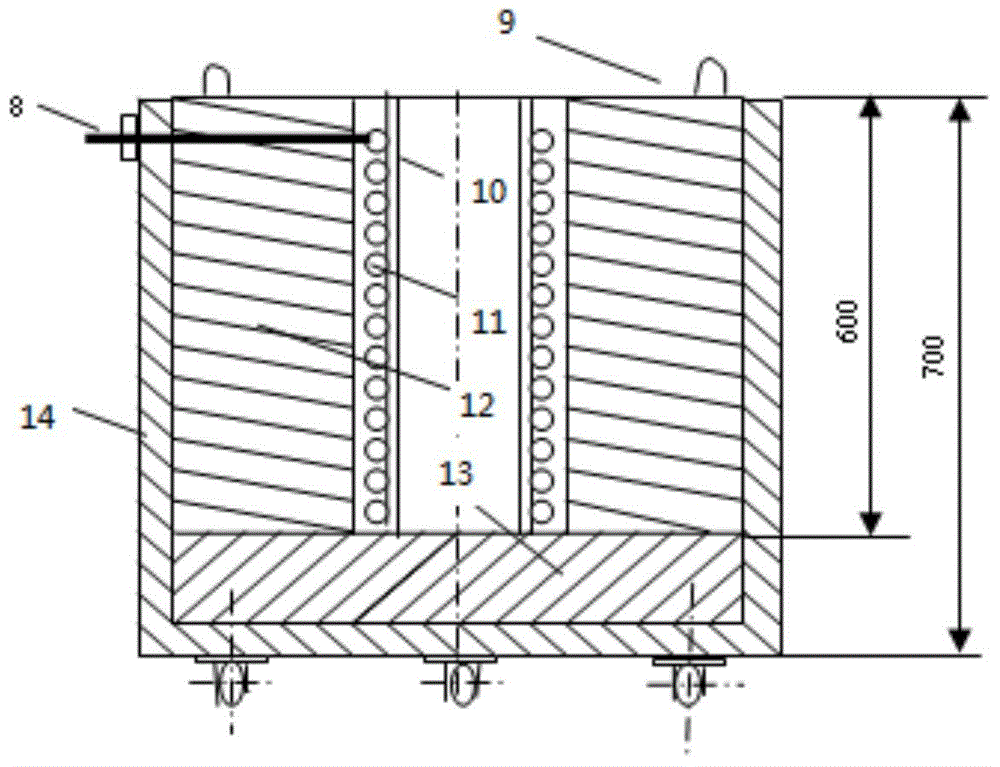

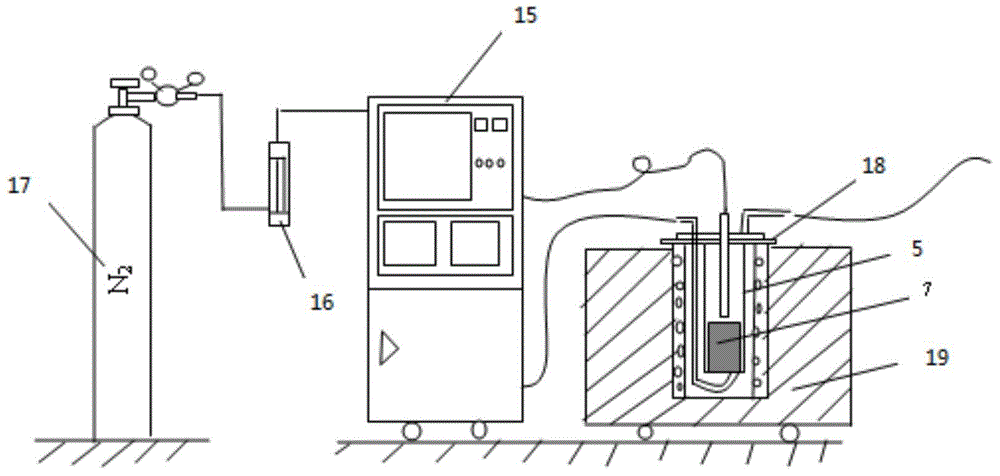

[0046] A method for preparing activated carbon using a coke reactivity measuring device, which is carried out using a coke reactivity measuring device. The structure of the coke reactivity measuring device is as follows Figure 1-Figure 3 As shown, the coke reactivity measuring device includes a coke reactor 5 and a gas supply system. The coke reactor is a closed container. The bottom of the coke reactor is connected with an inlet pipe 3, and the top is connected with an exhaust pipe 4, inside the coke reactor The center is provided with a central thermocouple 1, and the outer jacket of the central thermocouple 1 is provided with a central thermocouple sleeve 2. The coke reactor is placed in a sealed heating electric furnace 19, the sealed heating electric furnace 19 includes a furnace shell 14 and a furnace 10, and the furnace 10 is connected to The heating tube is connected. The furnace 10 is a double-layer casing. A heating furnace wire 11 is wound from bottom to top in the g...

Embodiment 2

[0053] Same as the method for preparing activated carbon using the coke reactivity measuring device described in Example 1, except that:

[0054] (1) Add 10g powder coke to 80g potassium hydroxide, grind it to 0.075mm, and move it into the crucible;

[0055] (2) Then add 16g of coal tar into the crucible, add 2.6ml of water and stir evenly, move the crucible into the coke reactor of the coke reactivity measuring device, cover the reactor cover, and place the coke reactor in the coke reactivity measuring device In the sealed heating electric furnace of the coke reactor, a temperature measuring thermocouple is installed in the inner center of the coke reactor. The temperature measuring thermocouple is connected to the temperature and gas flow automatic controller through the circuit, and the inlet pipe and exhaust pipe of the reactor are respectively connected with Air supply system and exhaust system connection;

[0056] (3) Turn on the temperature controller, and heat the coke react...

experiment example

[0074] The specific surface area and reaction time of the activated carbons prepared in Examples 1 to 2 and the activated carbons of Comparative Examples 1 to 5 were measured according to the prior art. The results are shown in Table 1 below.

[0075] Table 1: Performance comparison of activated carbon

[0076]

[0077] According to the data comparison in Table 1, the specific surface area of the activated carbon prepared by the treatment of Examples 1 to 2 is 1004.2m. 2 / g, the specific surface area of Example 2 is 1004.5m 2 / g, the average pore size is The highest specific surface area of the activated carbon of the comparative example can only reach 990.1m2 / g. By comparison, the activated carbon prepared by the coke reactivity measuring device prepared by the present invention has a large specific surface area up to 1005m2 / g, uniform pore size, and strong adsorption. In Comparative Example 1, the reaction was carried out in a resistance furnace. The airtightness and temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com