Micro-channel reaction assembly and micro-channel reactor

A technology of microchannel reactor and microchannel reaction, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc. Fully mix materials, insufficient and other problems to achieve the effect of reducing volume, strengthening pressure bearing and reducing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

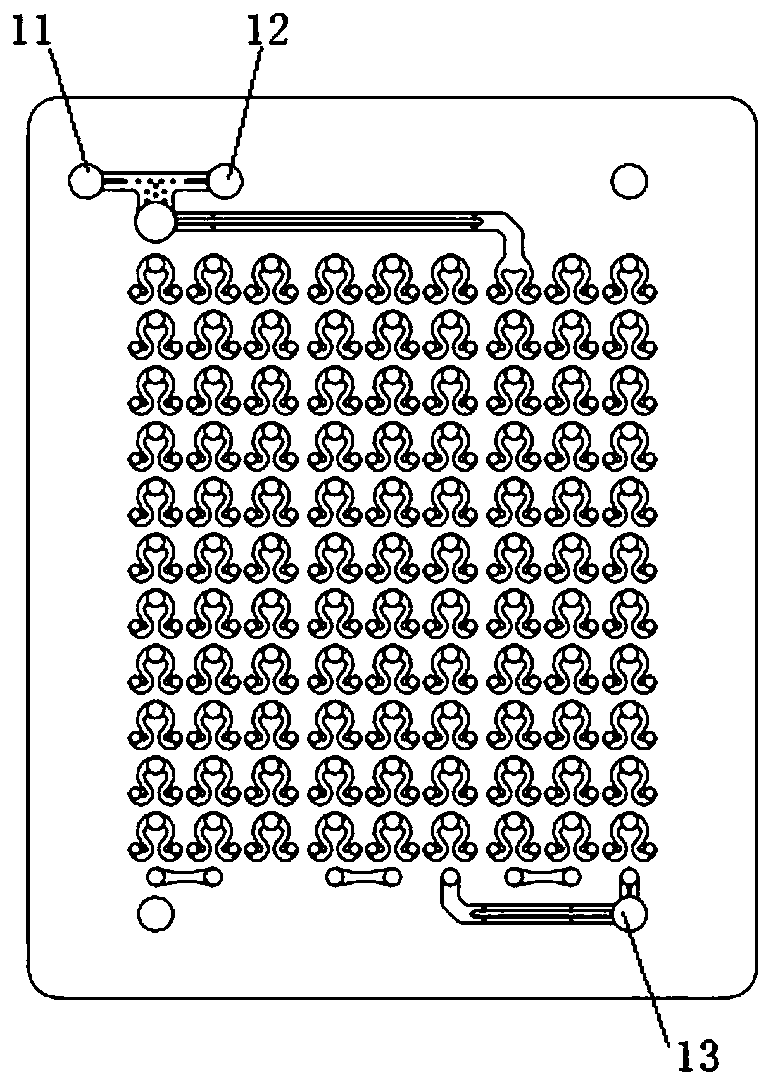

[0070] Such as Figure 2-4 , as shown in 6-8, the present embodiment provides a microchannel reaction assembly, including stacked settings:

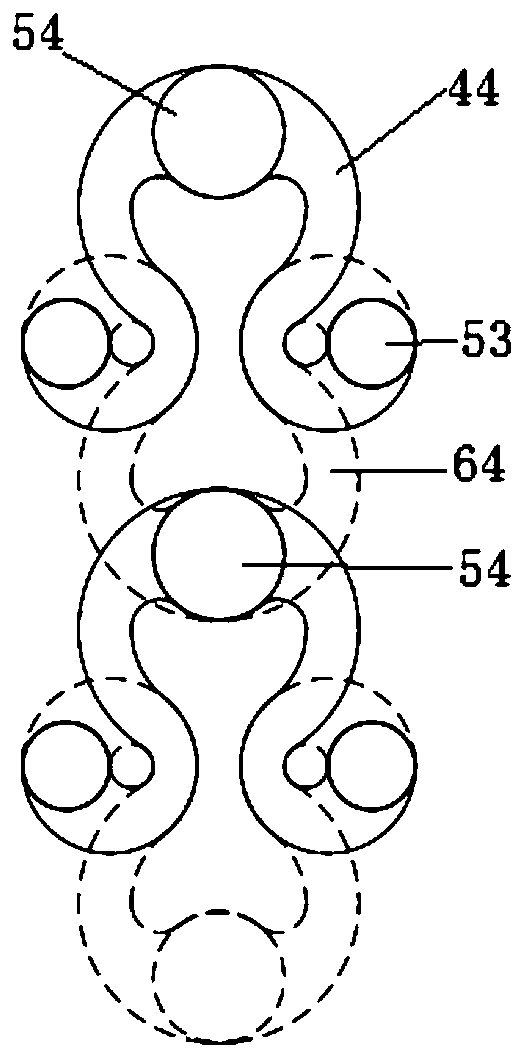

[0071] The first layer of passages is provided with a number of branch passages 44. The branch passages 44 are arranged in rows, and at least one row is arranged. Along the arrangement direction, the branch points of the branch passages 44 are set close to the first direction. At least two branches formed by points are disposed adjacent to a second direction opposite to said first direction;

[0072] The second layer of passages is provided with several confluence passages 64 on it, and the confluence passages 64 are arranged in rows, and at least one row is provided. The confluence of the point collection is arranged close to the first direction;

[0073] The communication channel is arranged between the first-layer channel and the second-layer channel, and at least one column of serial channels is arranged on it, and each column of t...

Embodiment 2

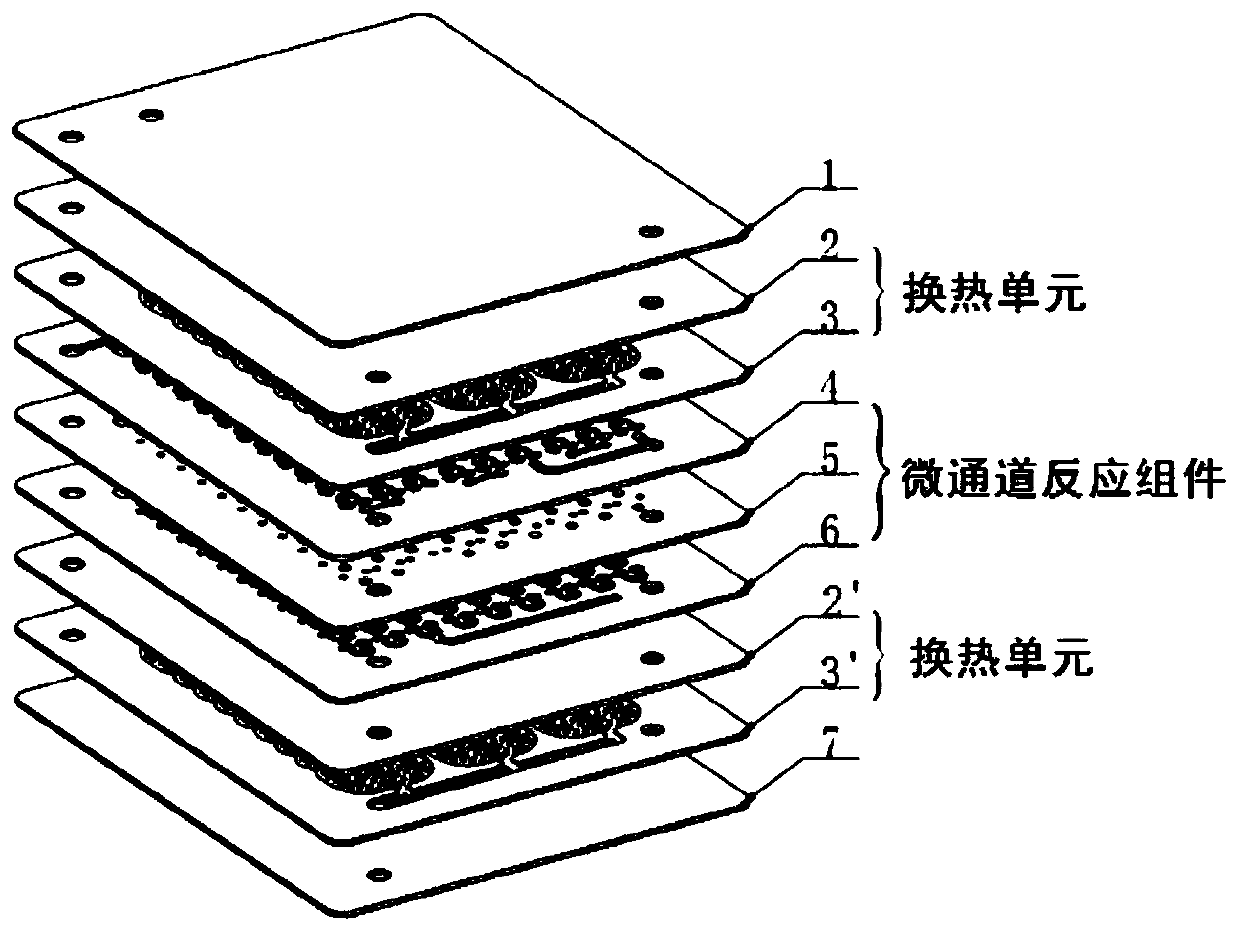

[0108] Such as Figure 1-9 As shown, this embodiment provides a microchannel reactor with the microchannel reaction assembly described in Example 1.

[0109] In the microchannel reactor provided in this embodiment, at least one side of the microchannel reaction component is stacked with a heat exchange unit, which can dissipate heat from the microchannel reaction component. The heat exchange unit includes two stacked heat exchange plates, a heat exchange medium channel is arranged between the two heat exchange plates, and a heat exchange medium inlet and a heat exchange medium outlet communicate with the heat exchange medium channel.

[0110] The microchannel reactor provided in this embodiment also includes: a heat exchange medium inlet and outlet plate 7, on which an initial heat exchange medium inlet 71 communicated with the heat exchange medium inlet, and an initial heat exchange medium inlet 71 communicated with the heat exchange medium outlet The final heat exchange med...

Embodiment 3

[0116] This embodiment provides a microchannel reaction assembly, which is different from the microchannel reaction assembly provided in Example 1 in that the microchannel reaction assembly is formed by processing a single plate, and the branch channel, confluence channel and serial flow The channels are all arranged on a single plate, which can reduce the material cost of the microchannel reaction components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com