Method for synthesizing high-carbon aldehyde by using microchannel reaction device

A technology of micro-channel reaction and micro-channel reactor, applied in the fields of carbon monoxide reaction preparation, organic chemistry, etc., can solve the problems of low reaction efficiency, high energy consumption of catalyst separation cycle, easy decomposition and mass transfer capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

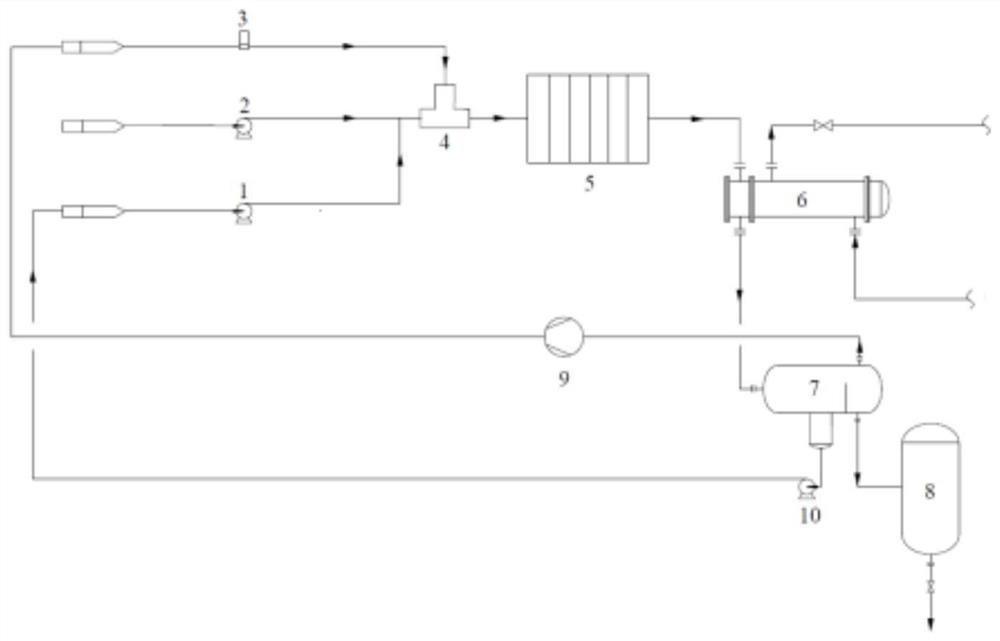

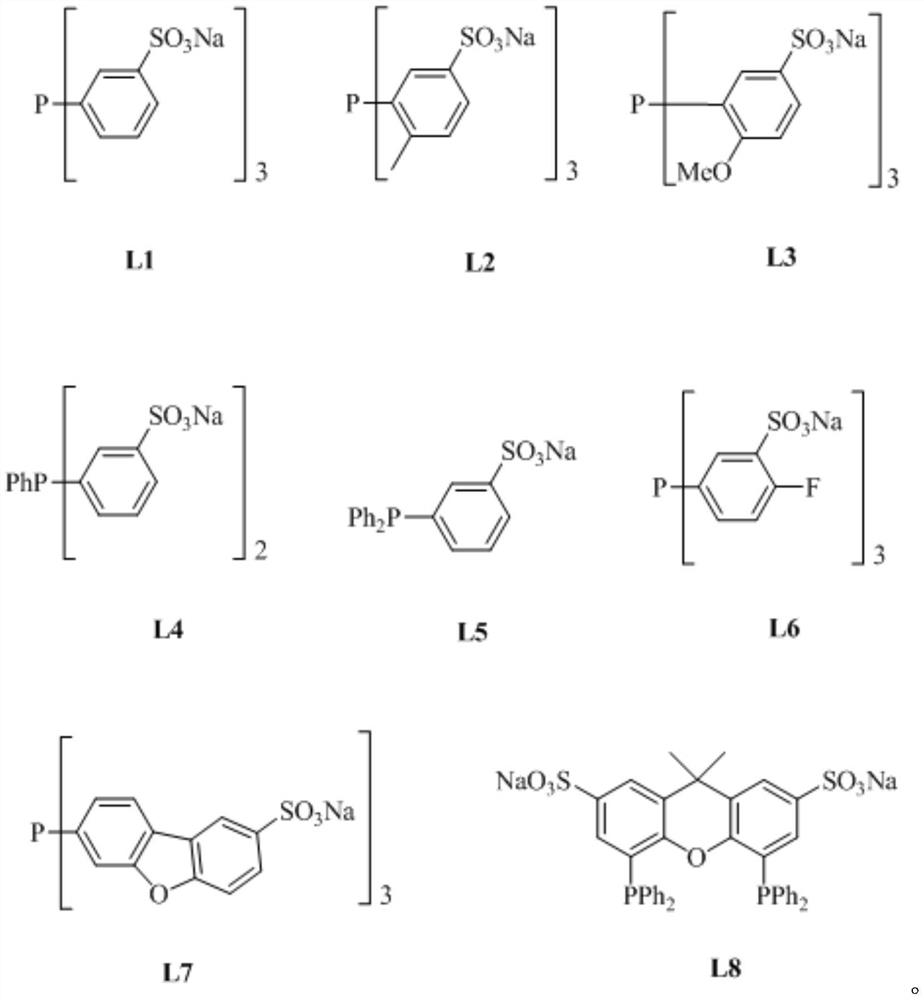

[0028] Dicarbonyl acetylacetonate rhodium, water-soluble phosphine ligand L1 and deionized water are configured into a catalyst solution, wherein the concentration of dicarbonyl acetylacetonate rhodium in water is 100ppm, and the mol ratio of dicarbonyl acetylacetonate rhodium to water-soluble phosphine ligand L1 The ratio is 1:100, the catalyst solution, synthesis gas and n-dodecene are passed into the microchannel mixer 4 simultaneously, and the ratio of n-dodecene and rhodium in the catalyst solution is controlled by the catalyst solution feed pump 1 and the higher carbon olefin feed pump 2. The molar ratio is 5000:1, and the molar ratio of syngas to n-dodecene is controlled to be 2:1 by the gas flow meter 3 and the high-carbon olefin feed pump 2, and the gas-liquid mixture is sent to the microchannel reactor 5 after mixing , at a reaction temperature of 100°C and a reaction pressure of 1 MPa, the reaction was carried out with a residence time of 60s. The obtained product e...

Embodiment 2

[0031] Dicarbonyl acetylacetonate rhodium, water-soluble phosphine ligand L2 and deionized water are configured into a catalyst solution, wherein the concentration of dicarbonyl acetylacetonate rhodium in water is 100ppm, and the mol ratio of dicarbonyl acetylacetonate rhodium to water-soluble phosphine ligand L2 The ratio is 1:100, the catalyst solution, synthesis gas and n-dodecene are passed into the microchannel mixer 4 simultaneously, and the ratio of n-dodecene and rhodium in the catalyst solution is controlled by the catalyst solution feed pump 1 and the higher carbon olefin feed pump 2. The molar ratio is 5000:1, and the molar ratio of syngas to n-dodecene is controlled to be 2:1 by the gas flow meter 3 and the high-carbon olefin feed pump 2, and the gas-liquid mixture is sent to the microchannel reactor 5 after mixing , at a reaction temperature of 100°C and a reaction pressure of 1 MPa, the reaction was carried out with a residence time of 60s. The obtained product e...

Embodiment 3

[0034] Dicarbonyl acetylacetonate rhodium, water-soluble phosphine ligand L3 and deionized water are configured into a catalyst solution, wherein the concentration of dicarbonyl acetylacetonate rhodium in water is 100ppm, and the mol ratio of dicarbonyl acetylacetonate rhodium to water-soluble phosphine ligand L3 The ratio is 1:100, the catalyst solution, synthesis gas and n-dodecene are passed into the microchannel mixer 4 simultaneously, and the ratio of n-dodecene and rhodium in the catalyst solution is controlled by the catalyst solution feed pump 1 and the higher carbon olefin feed pump 2. The molar ratio is 5000:1, and the molar ratio of syngas to n-dodecene is controlled to be 2:1 by the gas flow meter 3 and the high-carbon olefin feed pump 2, and the gas-liquid mixture is sent to the microchannel reactor 5 after mixing , at a reaction temperature of 100°C and a reaction pressure of 1 MPa, the reaction was carried out with a residence time of 60s. The obtained product e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com