Reaction device for synthesizing levo terpineol

The technology of a reaction device and terpineol is applied in the field of a reaction device for synthesizing L-terpineol, which can solve the problems affecting the yield of terpineol, wear of catalyst particles, and poor reaction selectivity, so as to prolong life, improve selectivity, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

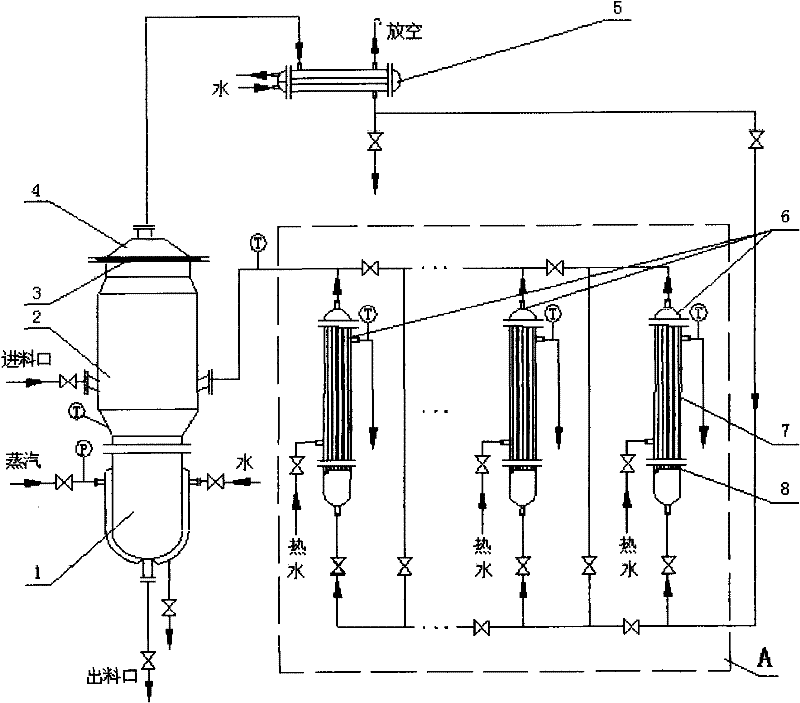

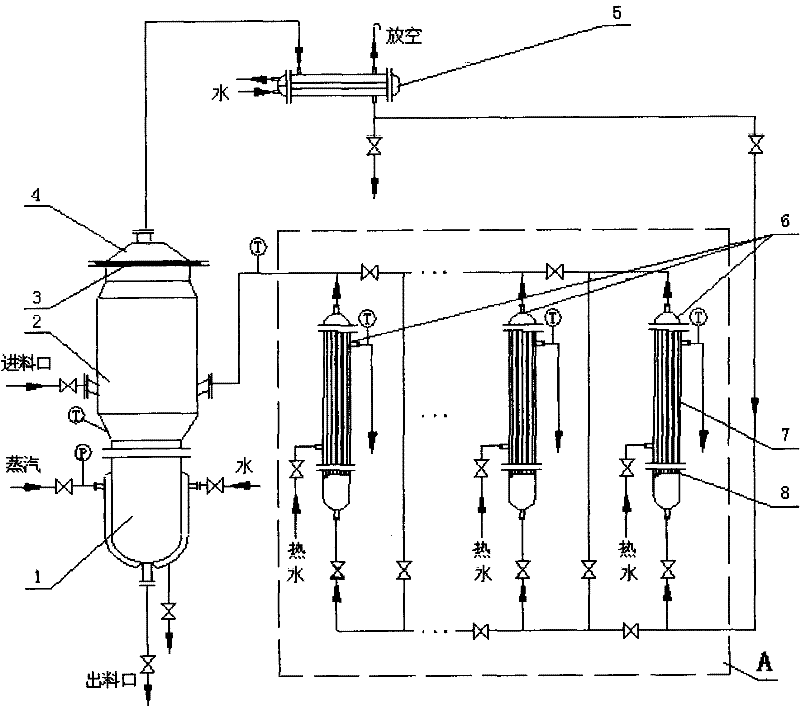

[0018] As shown in the figure, the device of the present invention mainly includes an evaporation kettle 4, a condenser 5, and a tubular fixed-bed reactor group A. The evaporation kettle 4 includes a heating kettle 1, an evaporation chamber 2 and a demister 3. The heating kettle 1 and the evaporation chamber 2 are connected as a whole through flange bolts, and the demister 3 is installed at the top flange of the evaporation chamber 2. The evaporator, condenser, and tubular fixed-bed reactor are all made of stainless steel, and the other parts are made of carbon steel; the demister is made of stainless steel. Tubular fixed-bed reactor group A is composed of 2 to 10 tubular fixed-bed reactors 6, and each tubular fixed-bed reactor 6 is controlled by pipes and valves, and combined into a whole in parallel or in series. Below the condenser 5. The tubular fixed-bed reactor 6 is provided with a catalyst loading tube 7 and a catalyst supporting plate 8, and the catalyst supporting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com