Continuous production method and continuous production equipment for 3, 4-dichloro-trifluorotoluene

A technology of dichlorobenzotrifluoride and p-chlorobenzotrifluoride, which is applied in the field of continuous production of 3,4-dichlorobenzotrifluoride, can solve the technical problems of continuous production that cannot be overcome, the continuous production process cannot be industrialized, Problems such as uneven residence time, to achieve high product yield, high production capacity, and precise control of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

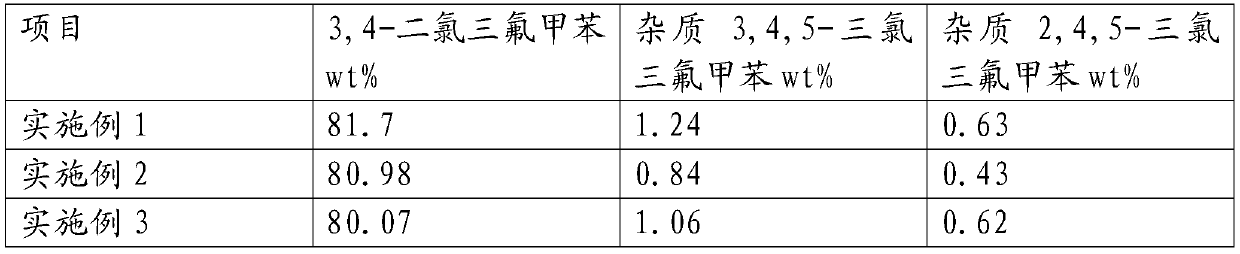

Embodiment 1

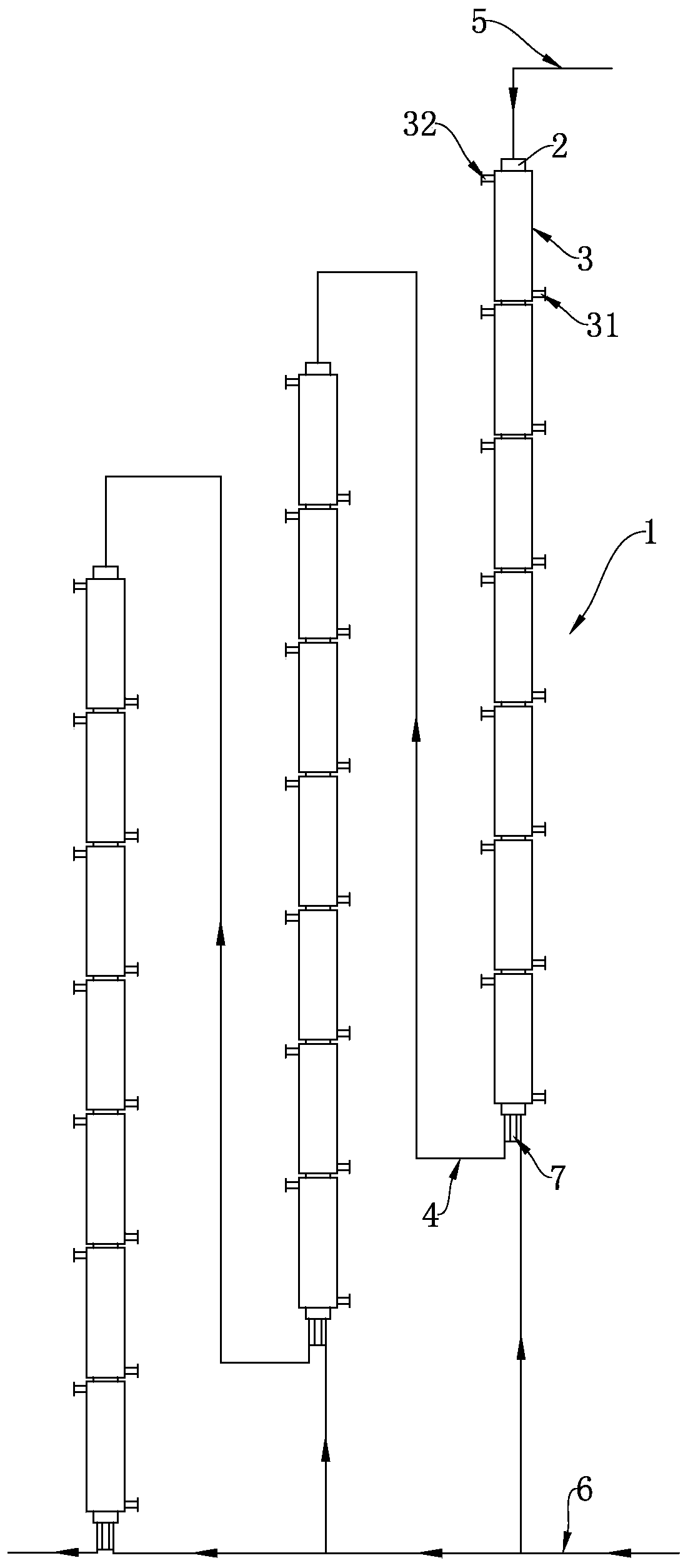

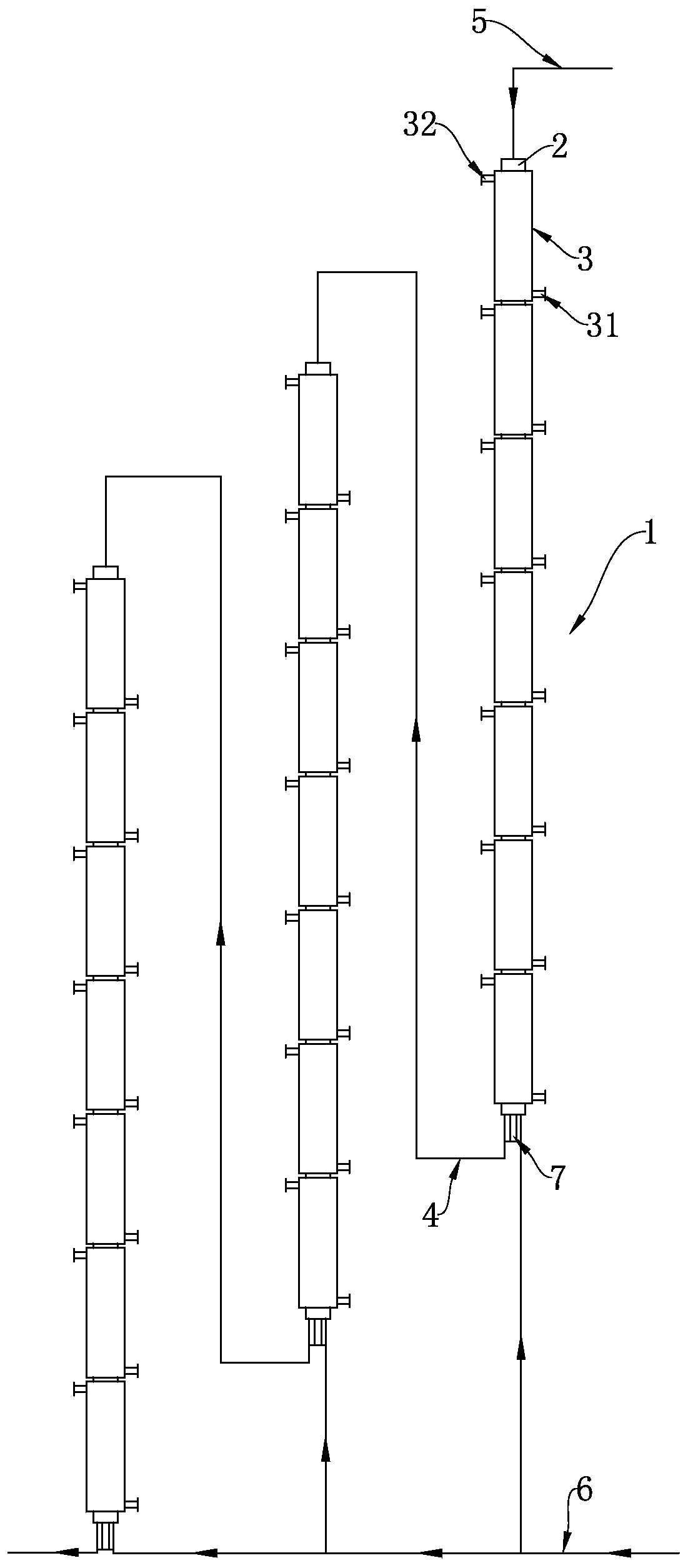

[0045] A continuous production equipment of 3,4-dichlorotrifluorotoluene comprises 3 stages of tubular reactors connected in series; each stage of tubular reactors is filled with iron shaving filler. The tubular reactors all include 7 sections of reaction tubes; each section of the reaction tube outer wall is provided with a separate temperature-regulating jacket, and each temperature-regulating jacket is provided with a separate temperature-control device; the bottom of each temperature-regulating jacket is provided with There are heat medium inlets and top heat medium outlets. The 3-stage tubular reactor is arranged in a ladder shape according to the height difference of 1 / 3 of the length of the tubular reactor; it is located between the bottom of the upper-stage tubular reactor and the top of the next-stage tubular reactor With overflow pipe. A feeding device is connected to the top of the first-stage tubular reactor, and the feeding device includes a feeding pipeline, a m...

Embodiment 2

[0047] A continuous production equipment for 3,4-dichlorotrifluorotoluene, comprising 4 stages of tubular reactors connected in series; each stage of tubular reactor is filled with iron Raschig ring packing. The tubular reactors all include 7 sections of reaction tubes; each section of the reaction tube outer wall is provided with a separate temperature-regulating jacket, and each temperature-regulating jacket is provided with a separate temperature-control device; the bottom of each temperature-regulating jacket is provided with There are heat medium inlets and top heat medium outlets. The 4-stage tubular reactor is arranged in a ladder shape according to the height difference of 1 / 4 of the length of the tubular reactor; it is located between the bottom of the upper-stage tubular reactor and the top of the next-stage tubular reactor With overflow pipe. A feeding device is connected to the top of the first-stage tubular reactor, and the feeding device includes a feeding pipel...

Embodiment 3

[0049] A continuous series of three-stage tubular reactors is used. The material of the reactor is carbon steel, filled with iron ladder ring packing, and the length of the tubular reactor is 7m; the diameter of the tubular reactor is 20mm; including 7 stages of reaction The length of each section of the reaction tube is 1m, and the jacket outside each section of the reaction tube is respectively fed with hot water to adjust the temperature. The three-stage tubular reactors are arranged in a ladder shape with a height difference of 1 / 3 of the length of the tubular reactors. The raw material p-chlorobenzotrifluoride enters from the top of the first-stage tubular reactor, and the feed flow rate is 6.0ml / min; min; the raw material ratio of p-chlorobenzotrifluoride and chlorine is 1:1.02; the reaction temperature of the three-stage continuous reaction is controlled according to the temperature gradient of 80 / 70 / 60°C, and each stage of the tubular reactor is top-down The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com