System and method for producing melamine

A production system and melamine technology, applied in the field of melamine preparation, can solve problems such as unreasonable heat utilization, increased energy consumption, environmental pollution, etc., and achieve the effects of increasing energy consumption, reducing dosage, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

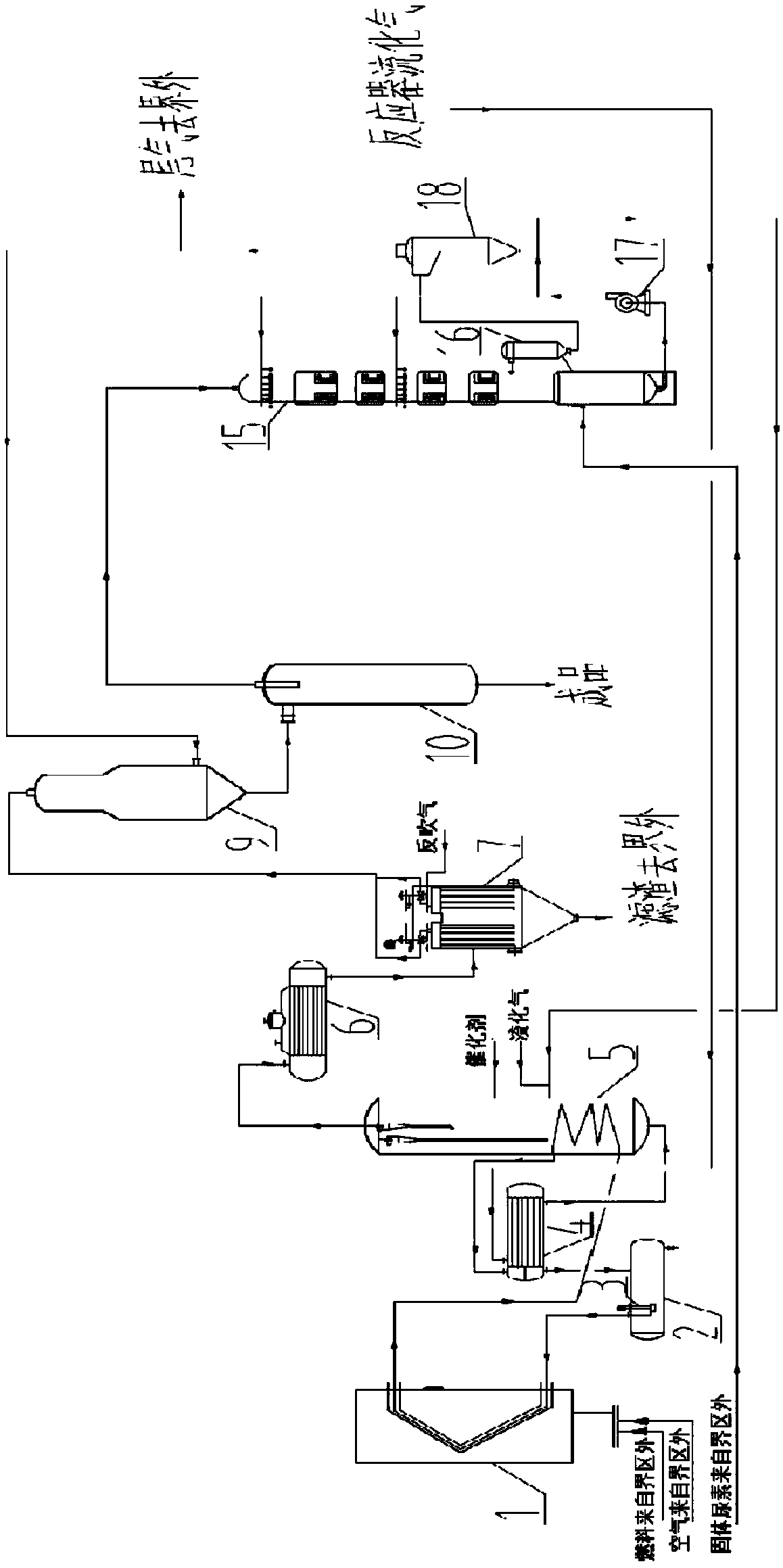

[0052] Such as figure 1 shown

[0053] A production system for melamine, comprising a fluidized bed reactor 5, the mixed gas generated by the fluidized bed reactor 5 sequentially enters a hot gas cooler 6, a hot gas filter 7, a crystallizer 9, a trap 10, and a urea scrubber 15 , gas-liquid separator 16, demister 18; demister 18 is connected with crystallizer 9; molten salt tank 2 is sequentially connected with molten salt furnace 1 and fluidized bed reactor 5 to provide heat exchange medium, carrier gas preheater 4 are respectively connected with the fluidized bed reactor 5 and the molten salt tank 2, and the molten salt enters the molten salt furnace 1, the fluidized bed reactor 5, the carrier gas preheater 4 and then returns to the molten salt tank 2 from the molten salt tank 2, The granular urea outside the boundary enters the lower part of the urea scrubber 15, and the molten urea flowing out from the bottom of the urea scrubber 15 enters the upper and middle parts of the...

Embodiment 2

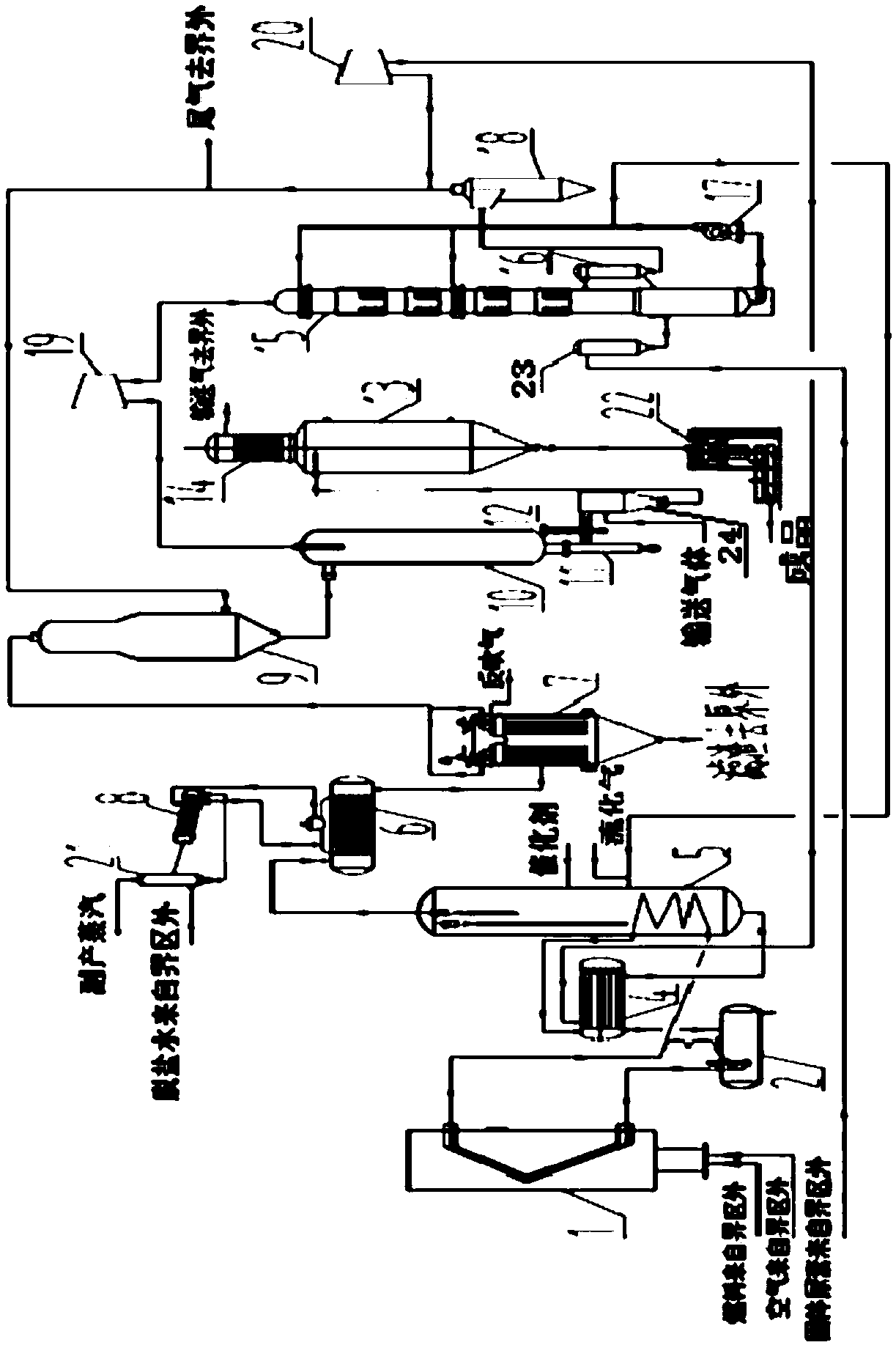

[0059] Such as figure 2 shown

[0060] A production system for melamine, comprising a fluidized bed reactor 5, the mixed gas generated by the fluidized bed reactor 5 sequentially enters a hot gas cooler 6, a hot gas filter 7, a crystallizer 9, a trap 10, and a urea scrubber 15 , gas-liquid separator 16, demister 18; demister 18 is connected with crystallizer 9; molten salt tank 2 is sequentially connected with molten salt furnace 1 and fluidized bed reactor 5 to provide heat exchange medium, carrier gas preheater 4 are respectively connected with the fluidized bed reactor 5 and the molten salt tank 2, and the molten salt enters the molten salt furnace 1, the fluidized bed reactor 5, the carrier gas preheater 4 and then returns to the molten salt tank 2 from the molten salt tank 2, The granular urea outside the boundary enters the lower part of the urea scrubber 15, and the molten urea flowing out from the bottom of the urea scrubber 15 enters the upper and middle parts of th...

Embodiment 3

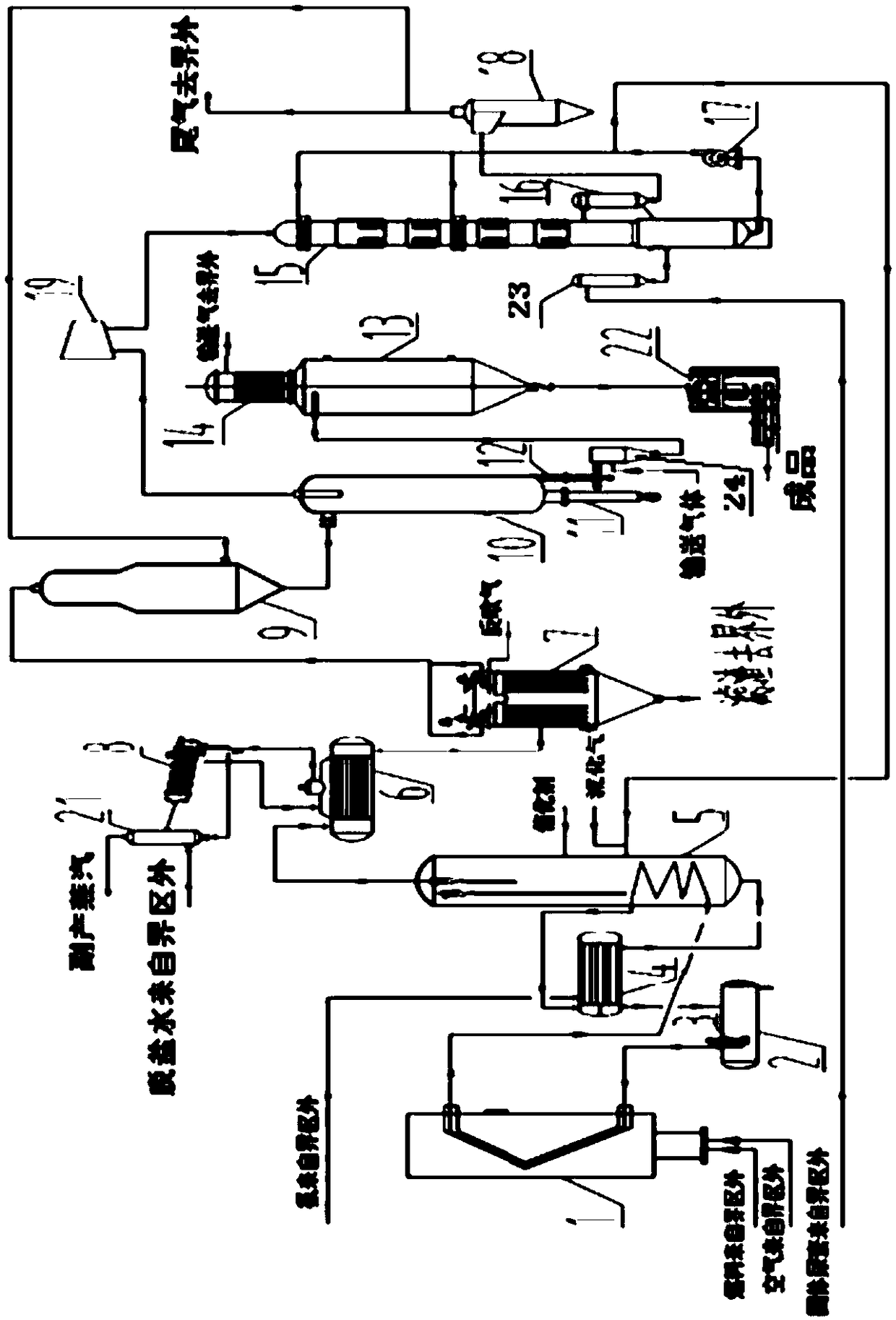

[0071] Such as image 3 shown

[0072] A production system for melamine, comprising a fluidized bed reactor 5, the mixed gas generated by the fluidized bed reactor 5 sequentially enters a hot gas cooler 6, a hot gas filter 7, a crystallizer 9, a trap 10, and a urea scrubber 15 , gas-liquid separator 16, demister 18; demister 18 is connected with crystallizer 9; molten salt tank 2 is sequentially connected with molten salt furnace 1 and fluidized bed reactor 5 to provide heat exchange medium, carrier gas preheater 4 are respectively connected with the fluidized bed reactor 5 and the molten salt tank 2, and the molten salt enters the molten salt furnace 1, the fluidized bed reactor 5, the carrier gas preheater 4 and then returns to the molten salt tank 2 from the molten salt tank 2, The granular urea outside the boundary enters the lower part of the urea scrubber 15, and the molten urea flowing out from the bottom of the urea scrubber 15 enters the upper and middle parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com