Patents

Literature

45results about How to "Complex process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

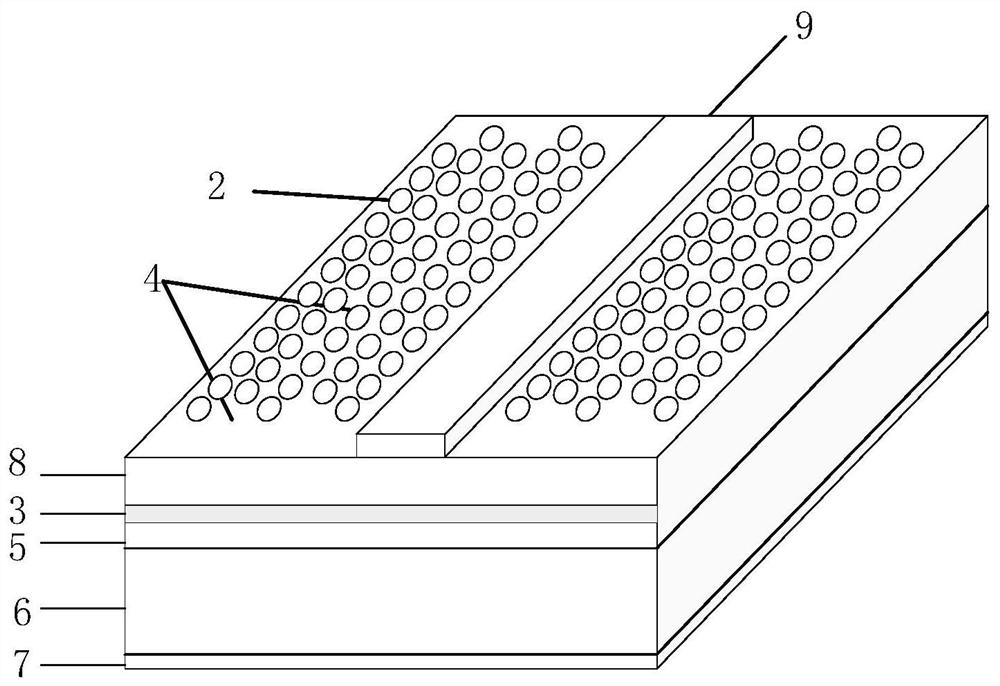

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

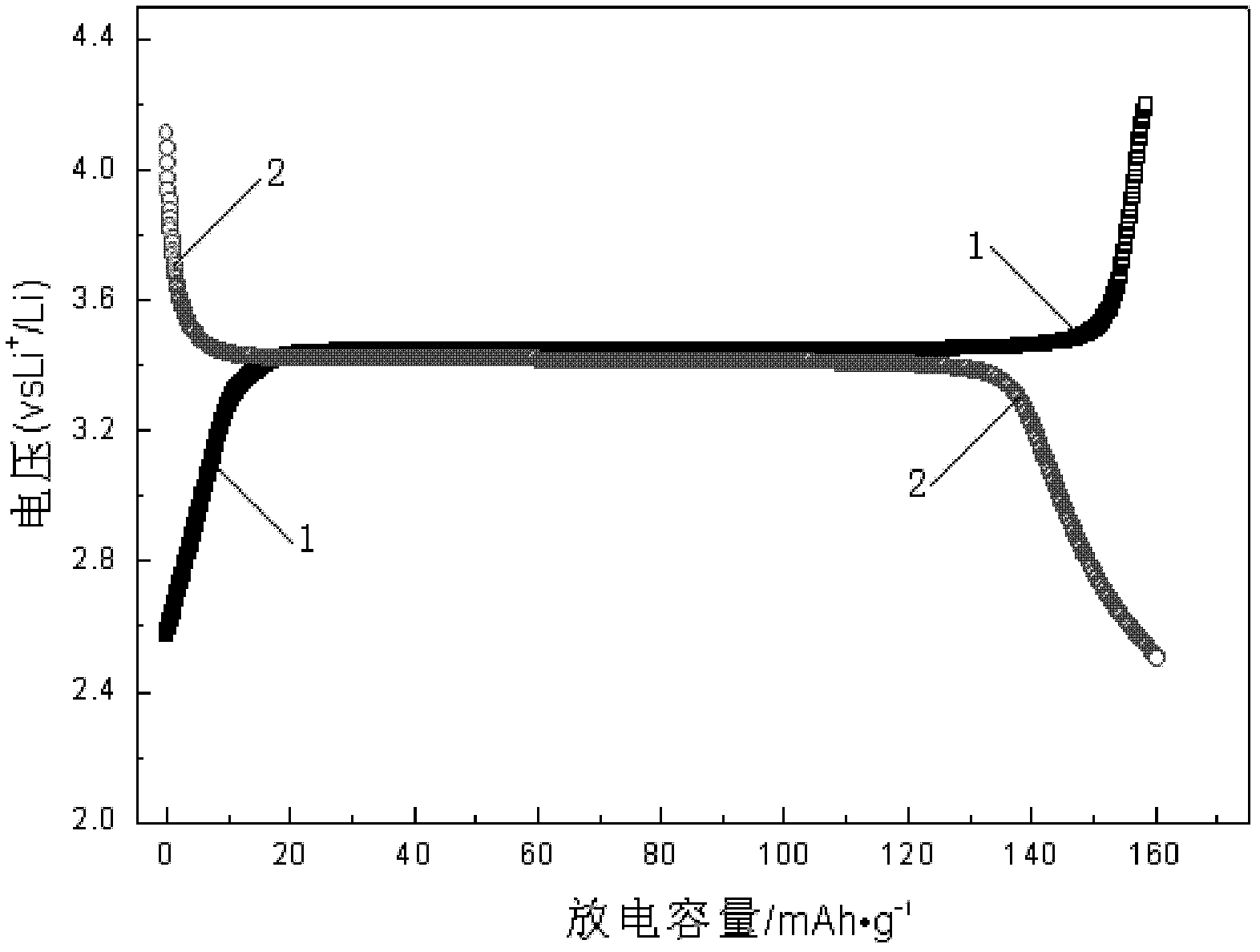

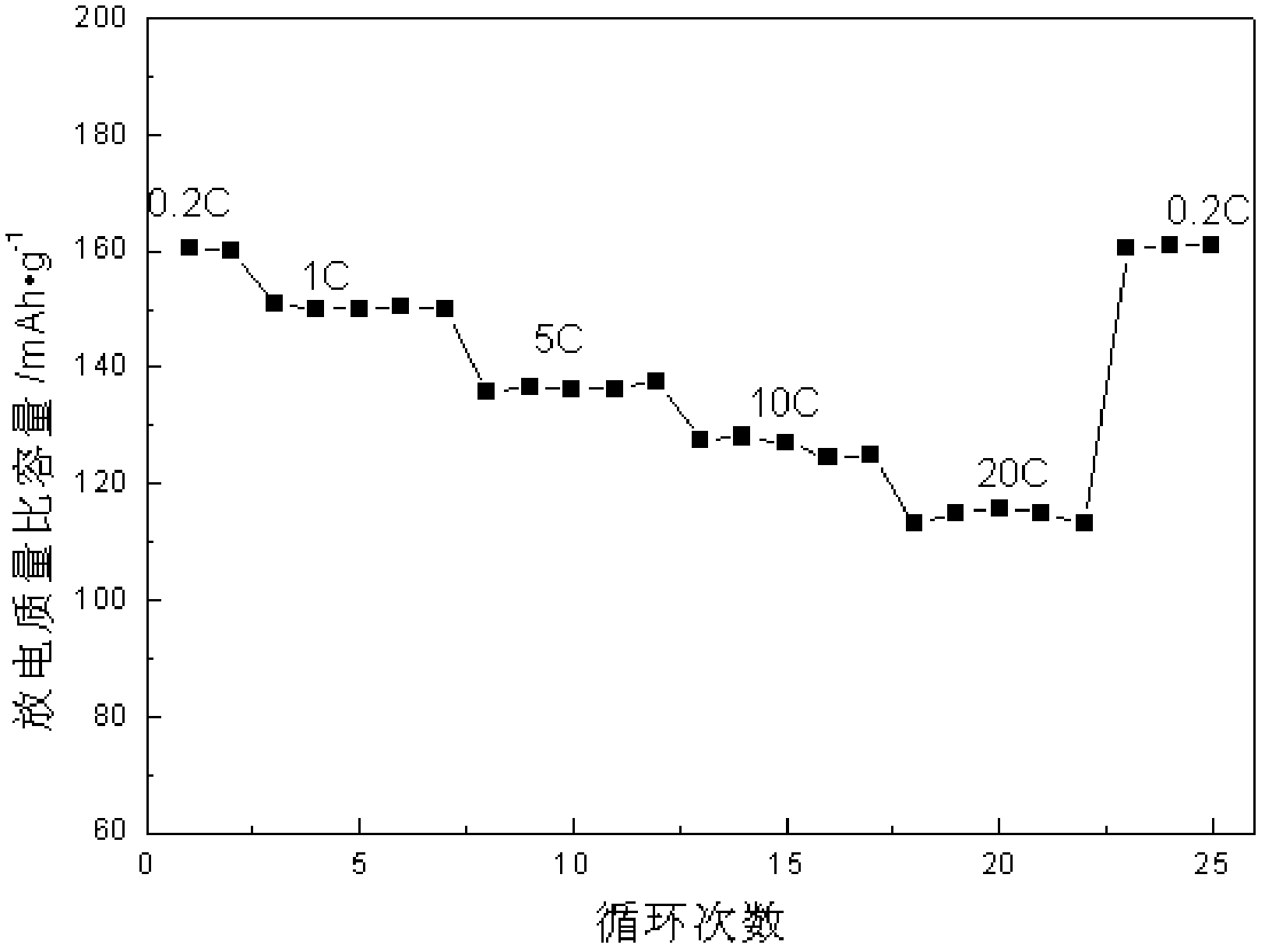

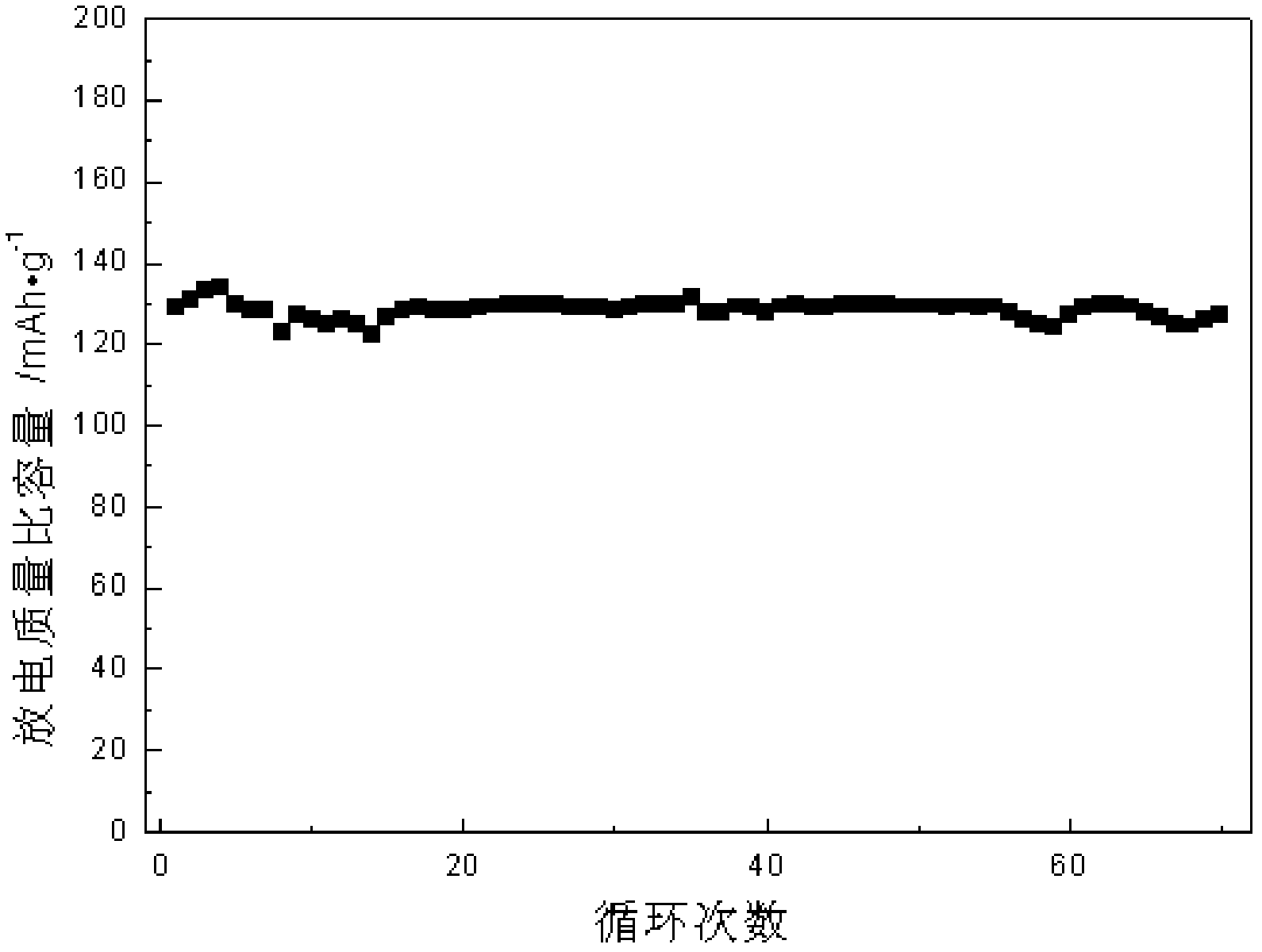

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

High stability color-less rosin pentaerythrite ester and its prepn

InactiveCN1772829ASimple processEasy to operateNatural resin chemical modificationPentaerythritolBoiling point

The present invention discloses one kind of high stability color-less rosin pentaerythrite ester with Hason color number smaller than 150, color change after being set in a drying tank at 180 deg.c for 8 hr not greater than 1 Ghana color number and color change after being irradiated with ultraviolet lamp for 15 hr not greater than 3 Ghana color number. Its preparation process includes the following steps: distilling rosin to obtain refined rosin; adding pentaerythritol, decolorizing agent, antioxidant and catalyst to refined rosin for esterification until reaching acid value lower than 20 mg / g; decompressing to eliminate low boiling point matter; cooling, adding heat stabilizer and light stabilizer via stirring to obtain the high stability color-less rosin pentaerythrite ester. The present invention has simple technological process and low production cost.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

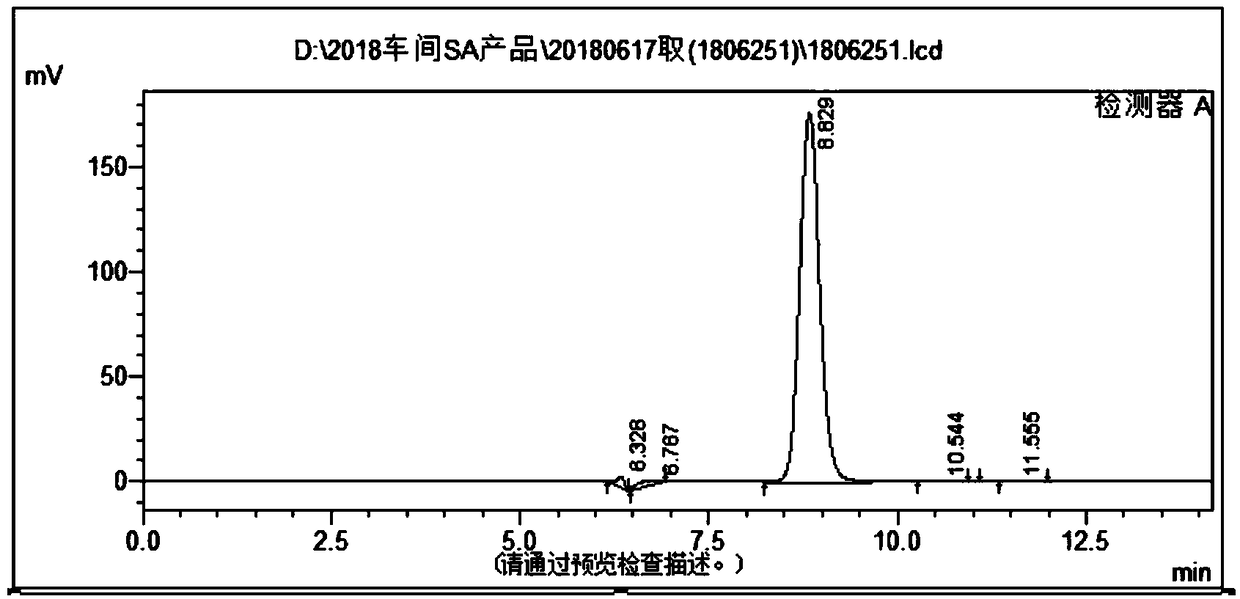

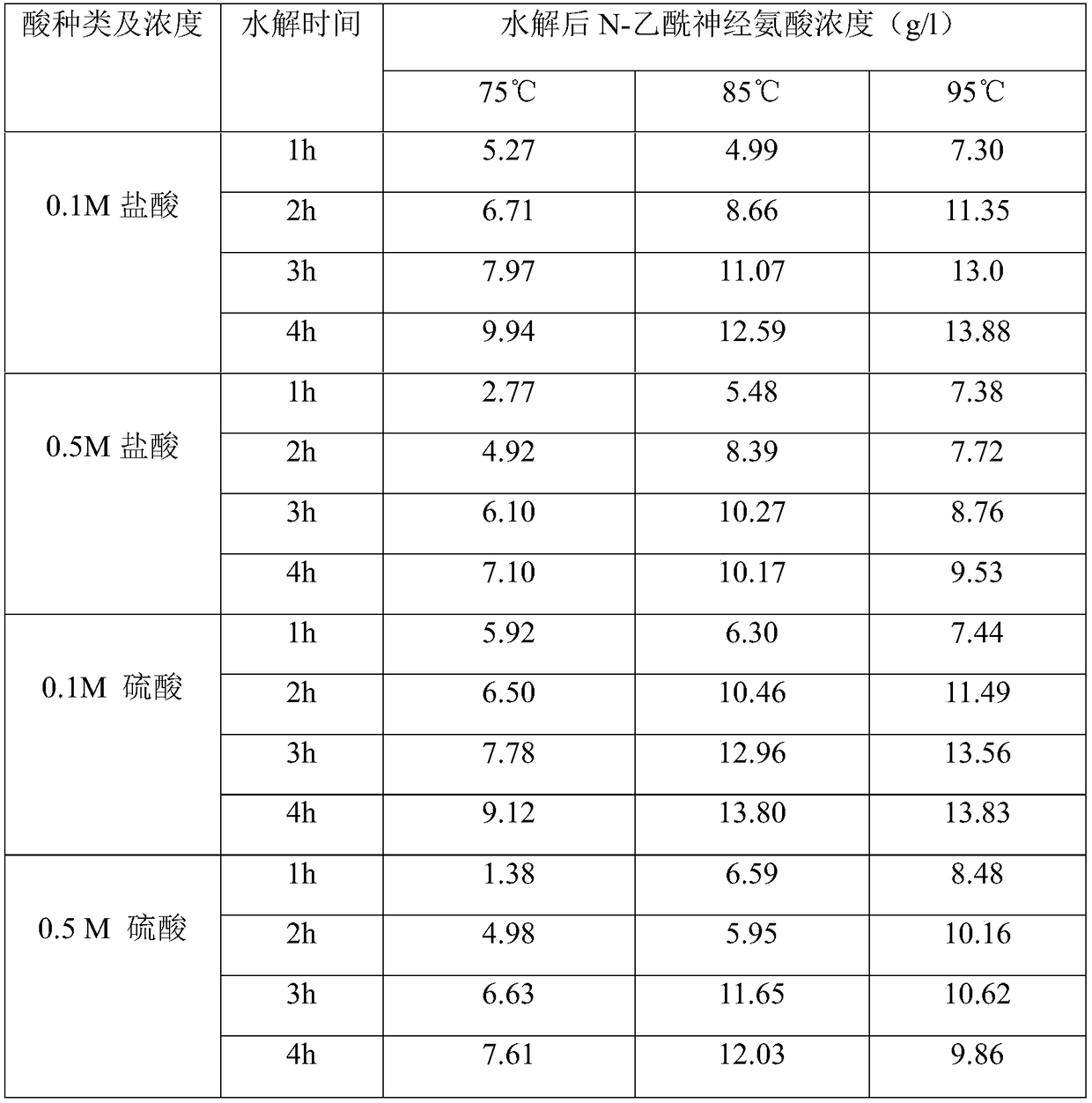

Method for separating and purifying N-acetylneuraminic acid from material containing polysialic acid

ActiveCN109180745ASimple stepsTo satisfy the market's needsSugar derivativesSaccharide compounds with non-saccharide radicalsN acetylneuraminatePolysialic acid

The invention discloses a method for separating and purifying N-acetylneuraminic acid from a material containing polysialic acid. The method utilizes a material containing polysialic acid as a raw material, comprises bacterium and solid removal, protein removal, decolorization, hydrolysis, desalting and crystallization and can produce a high-purity N-acetylneuraminic acid product with purity of atleast 98%. The high-purity N-acetylneuraminic acid product can meet the requirements in the fields of foods, health care, medicines and cosmetics. The method is simple and easy to operate and is particularly suitable for industrial fermentation production of N-acetylneuraminic acid.

Owner:武汉中科光谷绿色生物技术有限公司

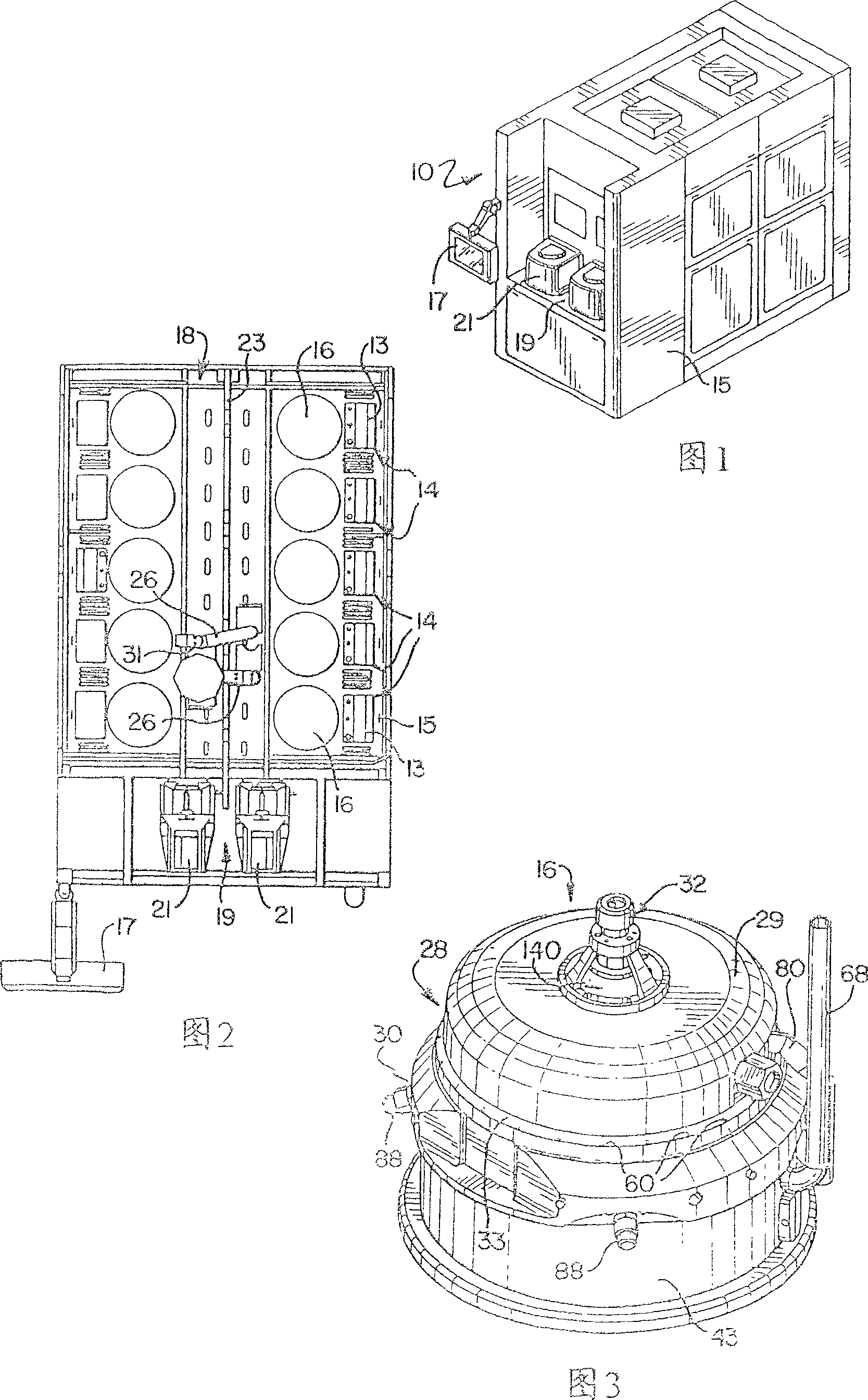

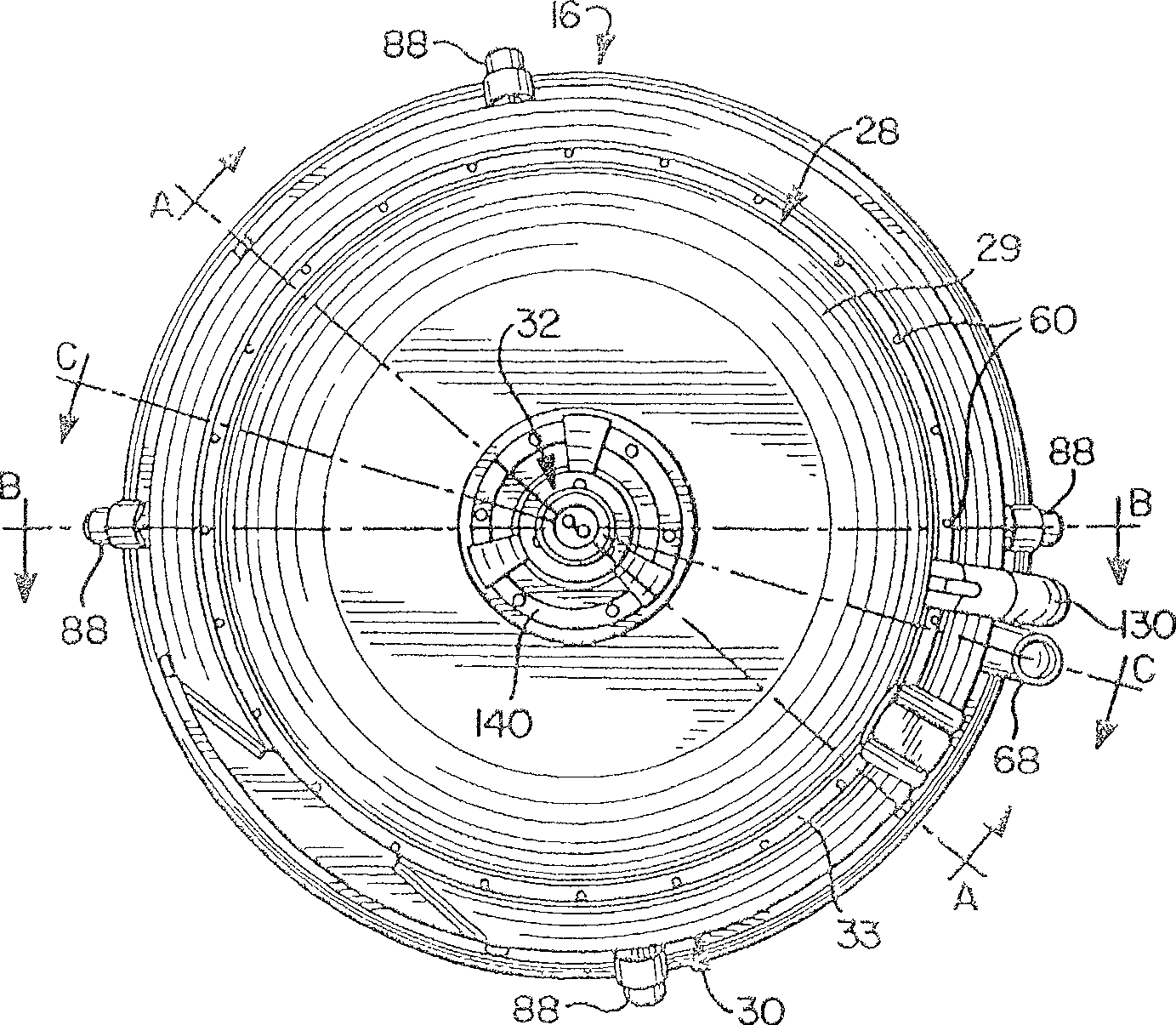

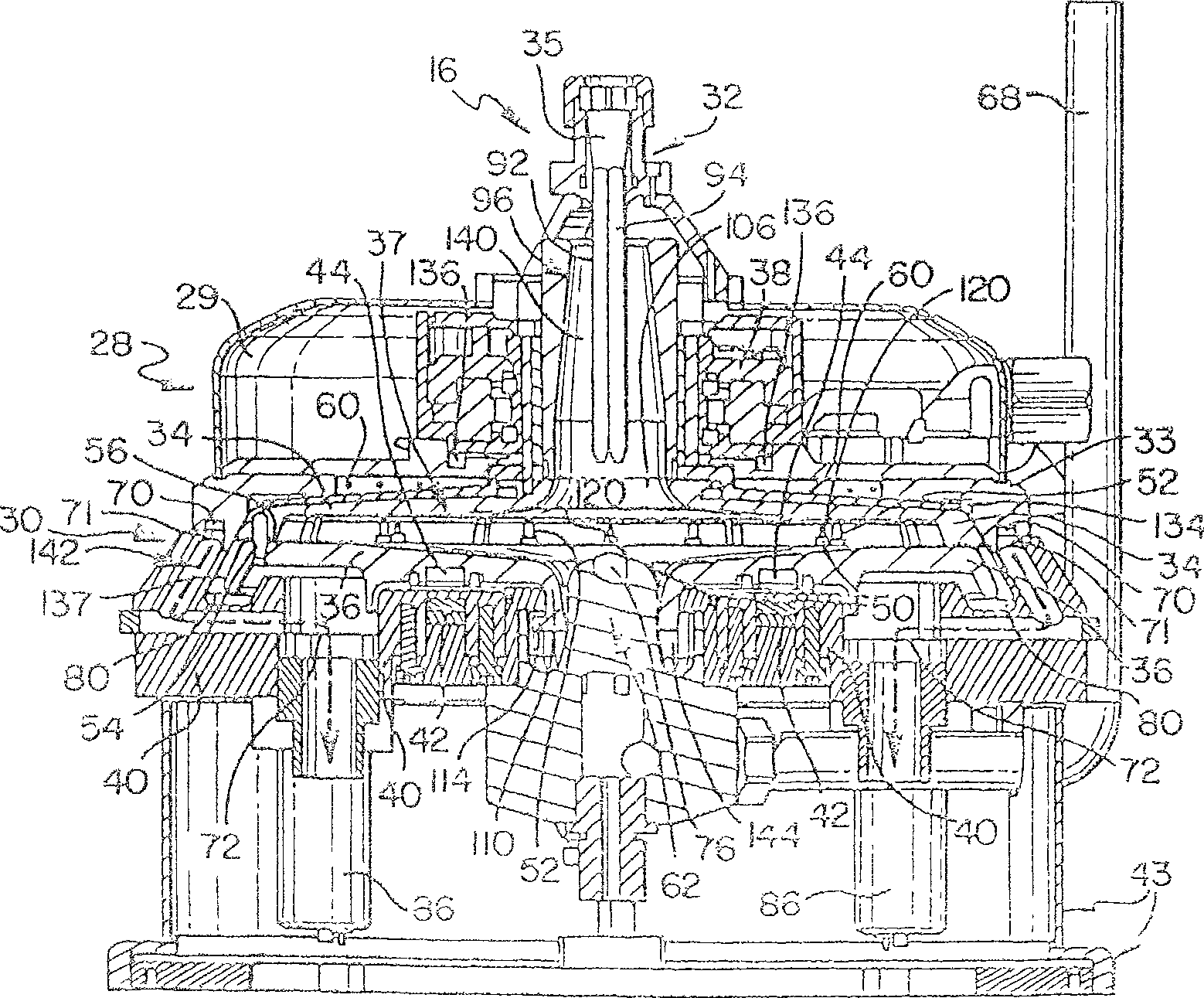

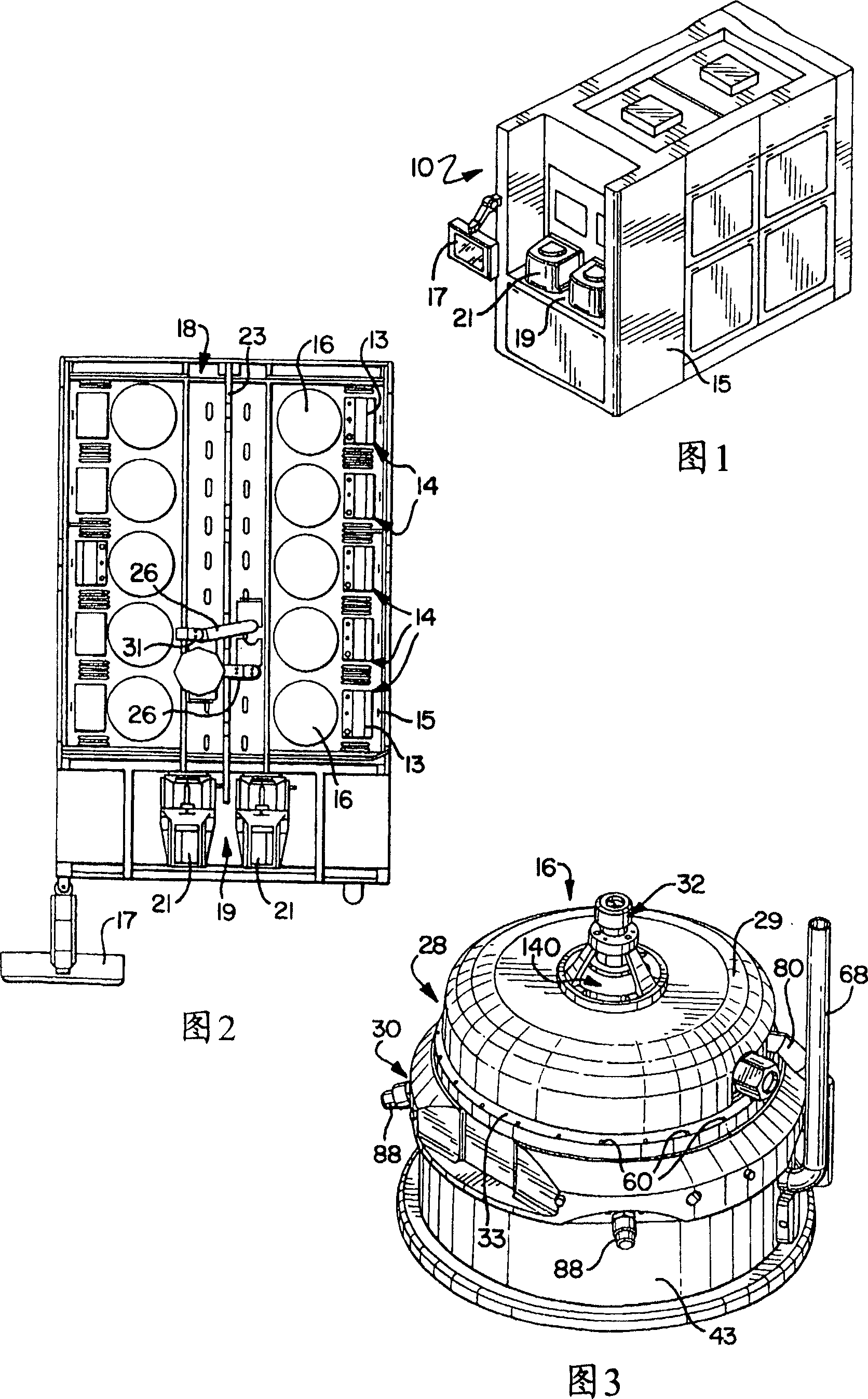

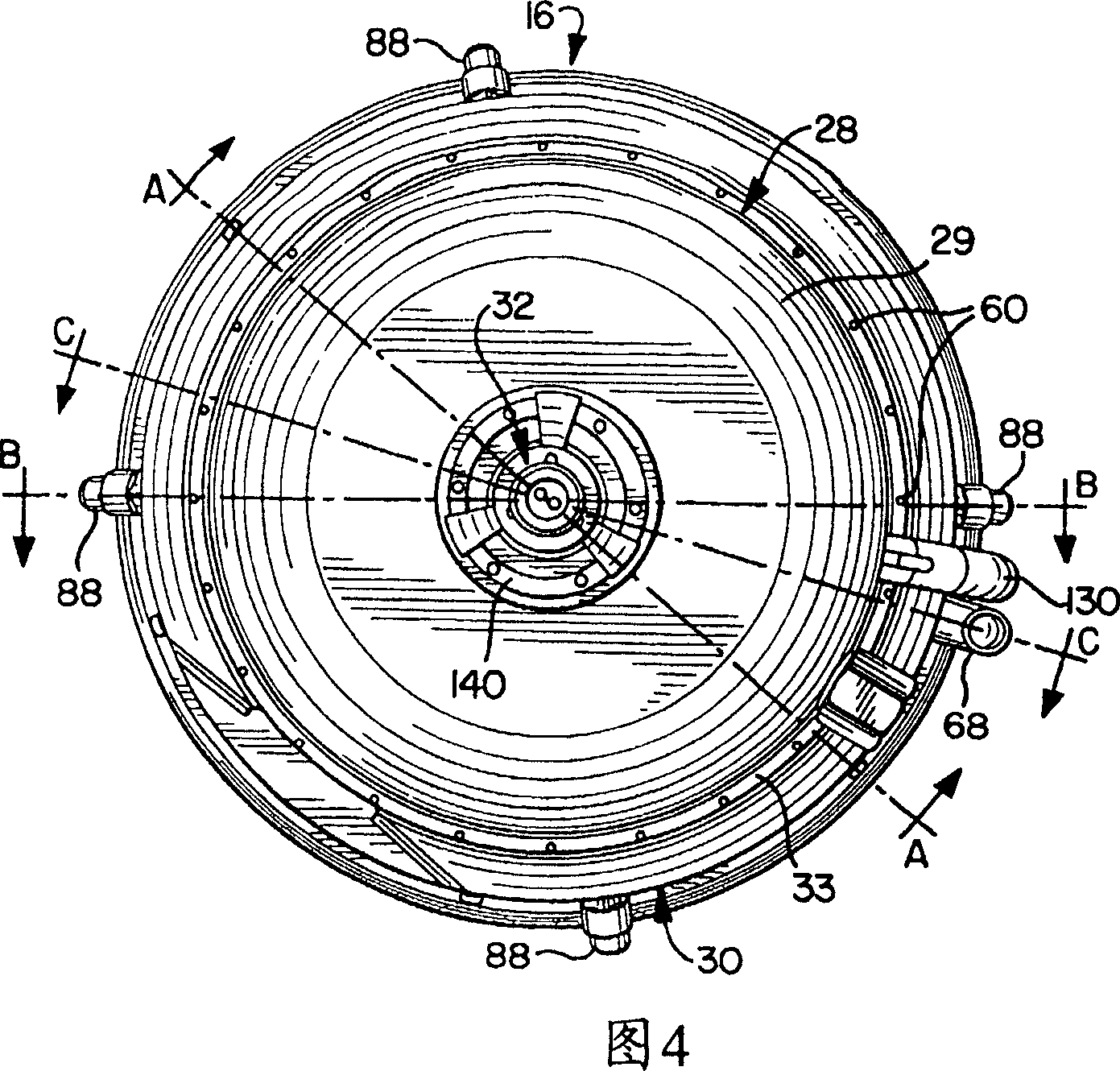

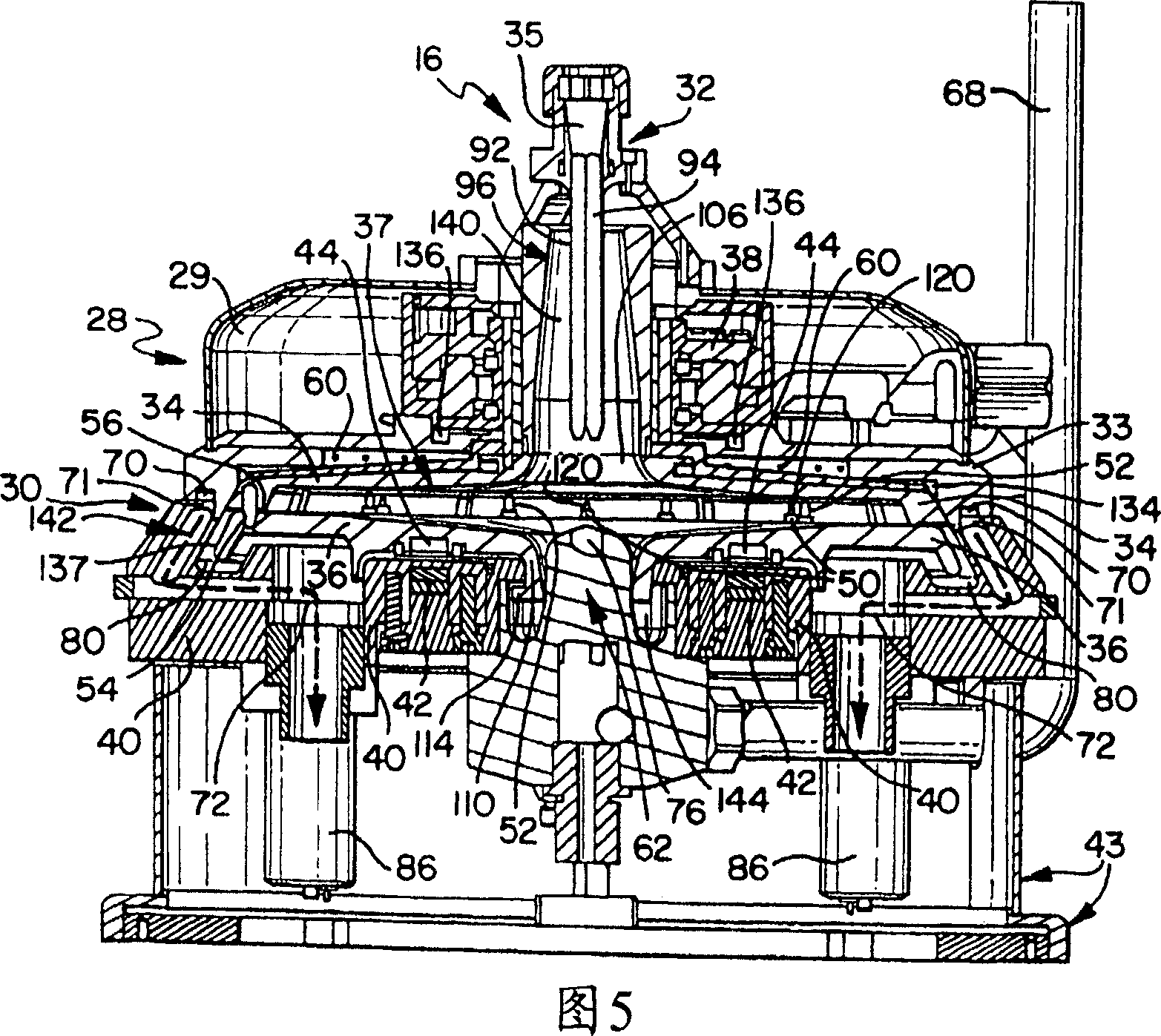

Workpiece processing system

InactiveCN100487855CReduce cross contaminationEasy to handleLiquid surface applicatorsSemiconductor/solid-state device manufacturingParticulatesRotor magnets

A system for handling workpieces includes a handling head assembly and a base assembly. The treatment head assembly has a treatment head and an upper rotor. The base assembly has a base and a lower rotor. The base and the lower rotor have magnets, wherein the upper rotor can engage the lower rotor by magnetic force generated by the magnets. The joined upper and lower rotors form a processing chamber in which semiconductor wafers are positioned for processing. A treatment fluid for treating the workpiece is introduced into the treatment chamber, optionally as the treatment head rotates the workpiece. Additionally, airflow around and through the processing chamber is controlled to reduce particulate additions to the workpiece.

Owner:APPLIED MATERIALS INC

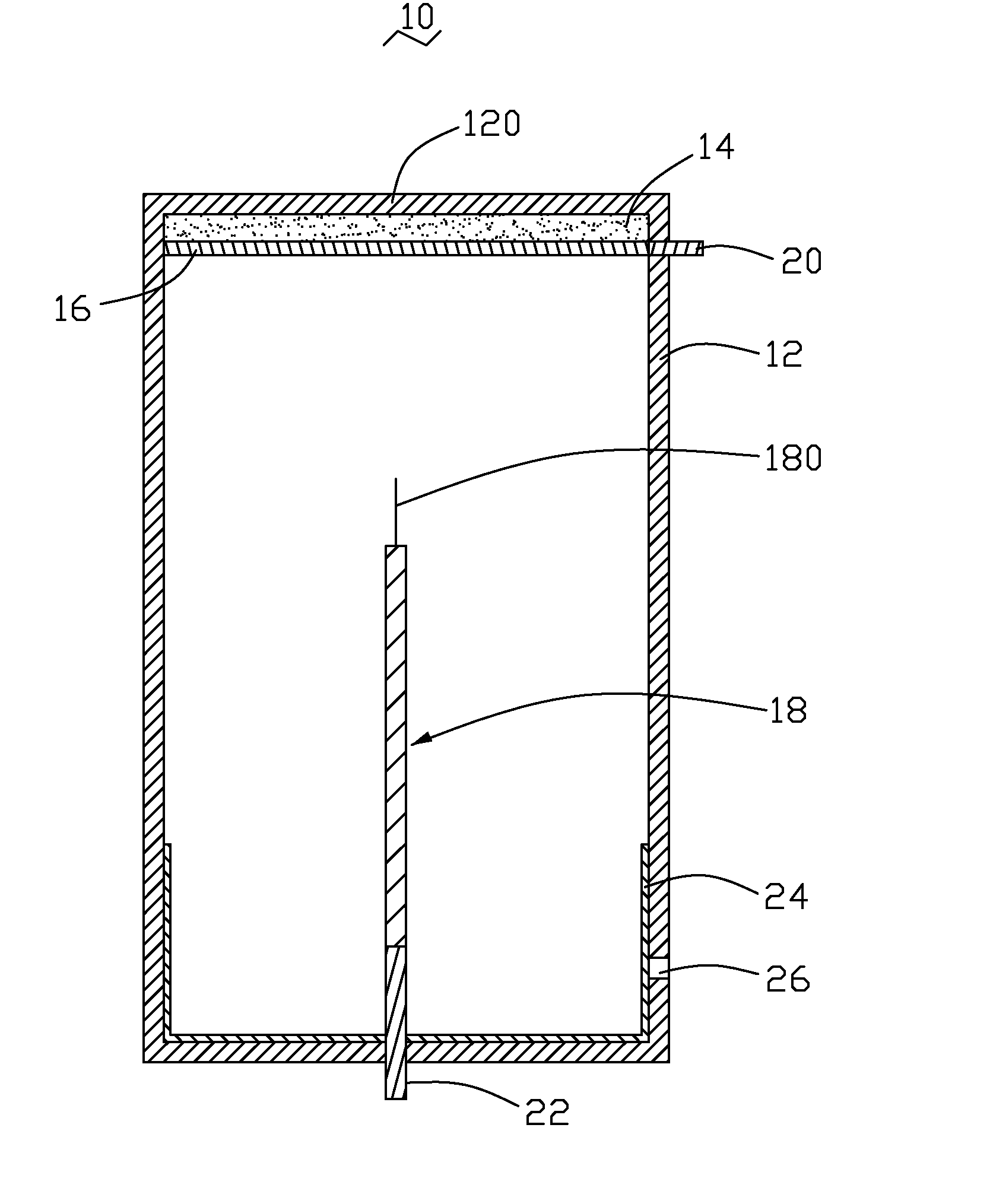

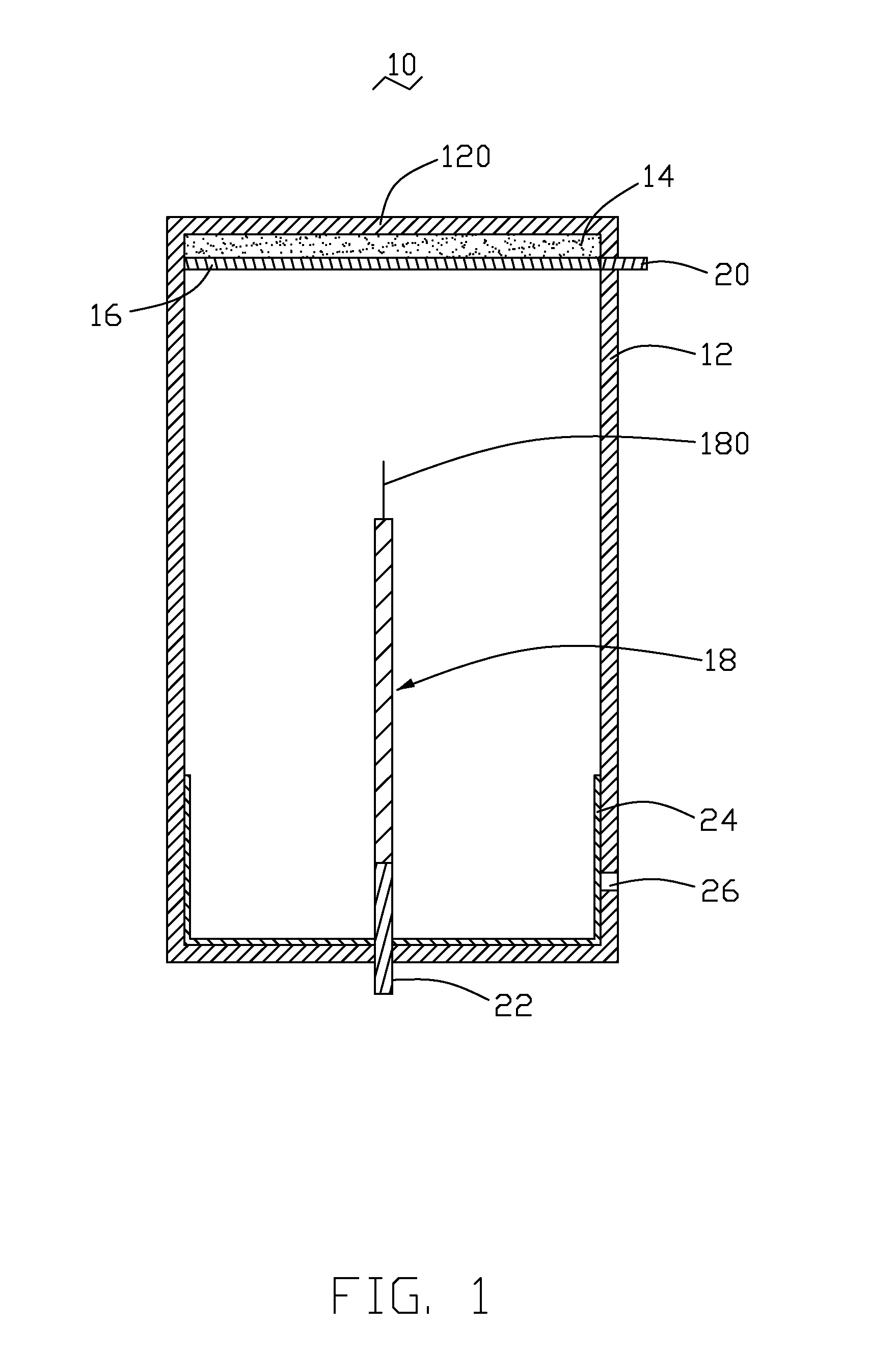

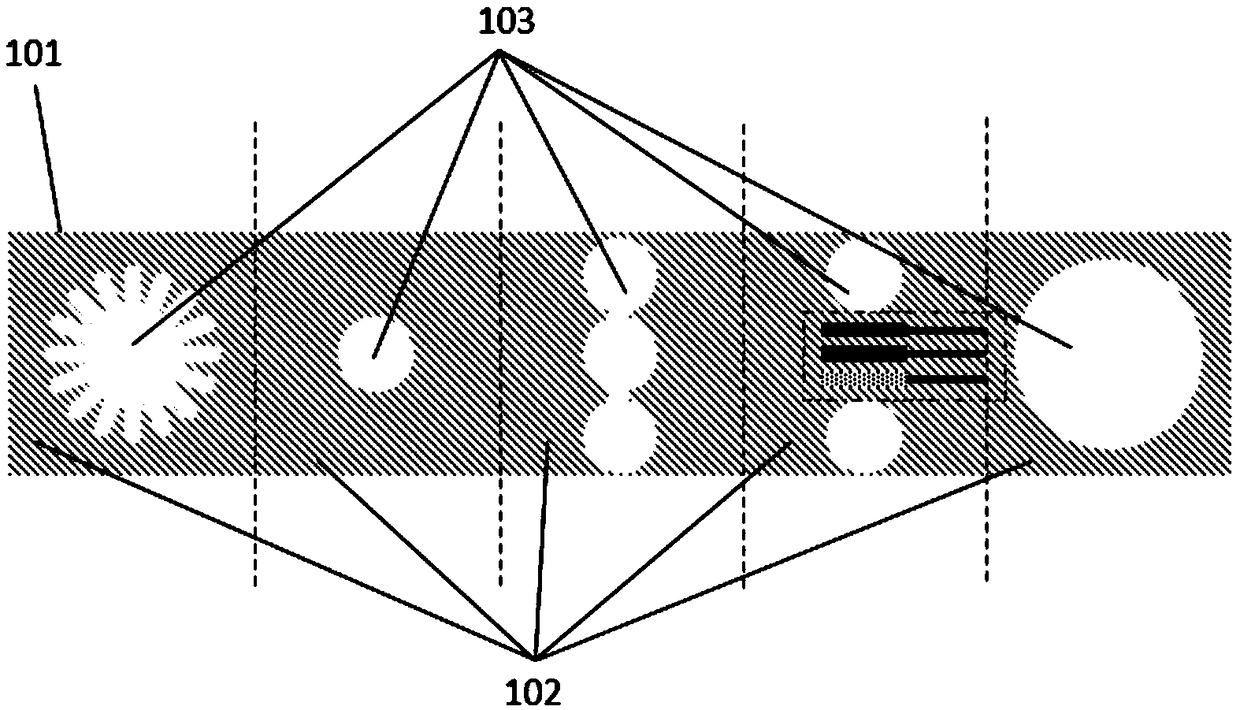

Field emission device

InactiveUS20080012466A1Powerful field emission enhancerSmall diameterDischarge tube luminescnet screensCathode ray tubes/electron beam tubesField emission deviceOrganic solvent

A field emission device (10) includes a sealed container (12) with a light permeable portion (120). A phosphor layer (14) and a light permeable anode (16) are coated on inside surface of the light permeable portion in succession. A cathode (18) is enclosed in the sealed container. A carbon nanotube yarn is attached to the cathode facing the light permeable portion. Before being embedded into the sealed container, the carbon nanotube yarn is processed in the following steps: providing a carbon nanotube array, drawing out at least one carbon nanotube yarn string from the carbon nanotube array, treating the at least one carbon nanotube yarn string using an organic solvent in a manner such that the at least one carbon nanotube yarn string is formed into a single strand of carbon nanotube yarn, and heating the single strand of the carbon nanotube yarn.

Owner:TSINGHUA UNIV +1

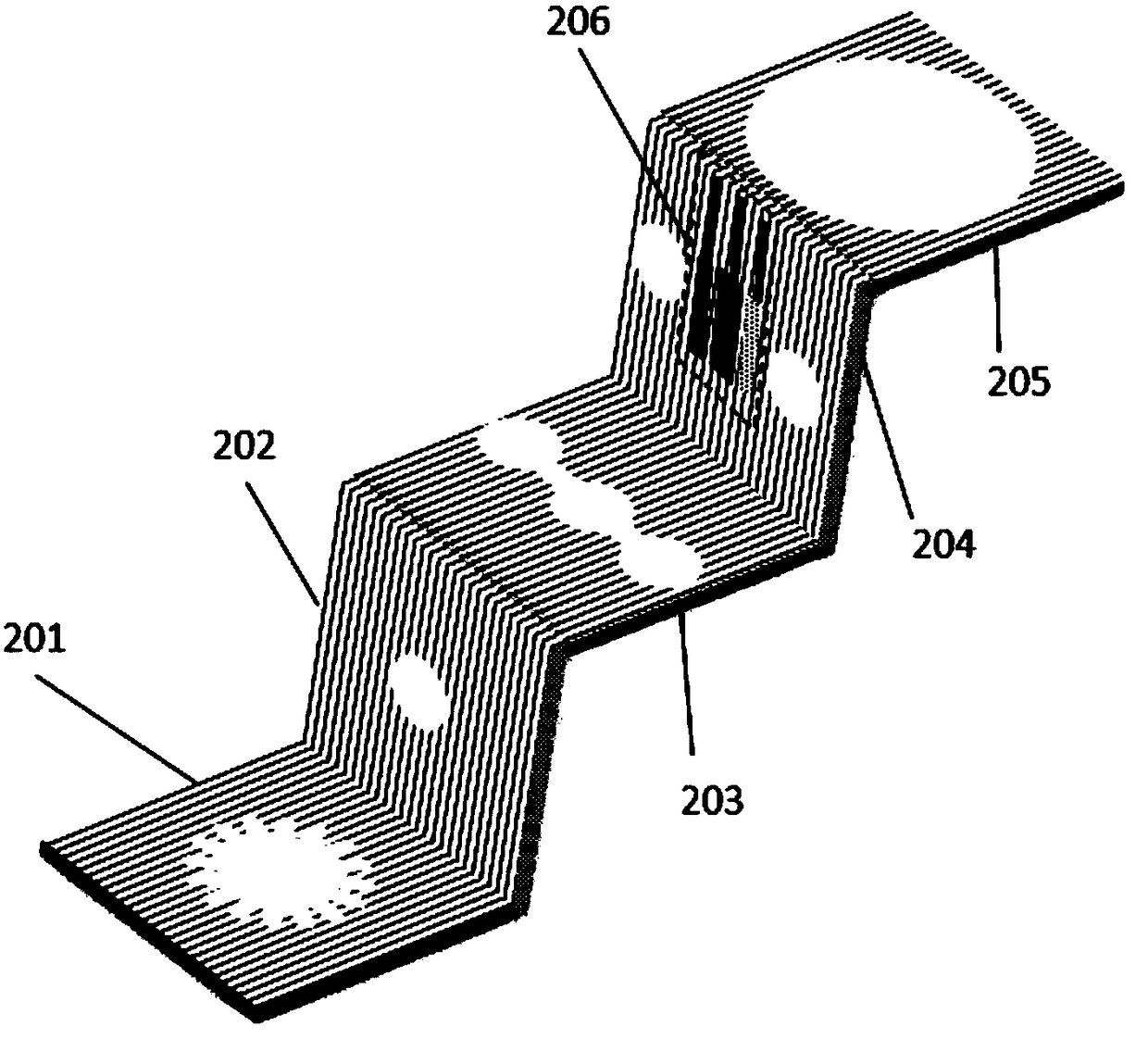

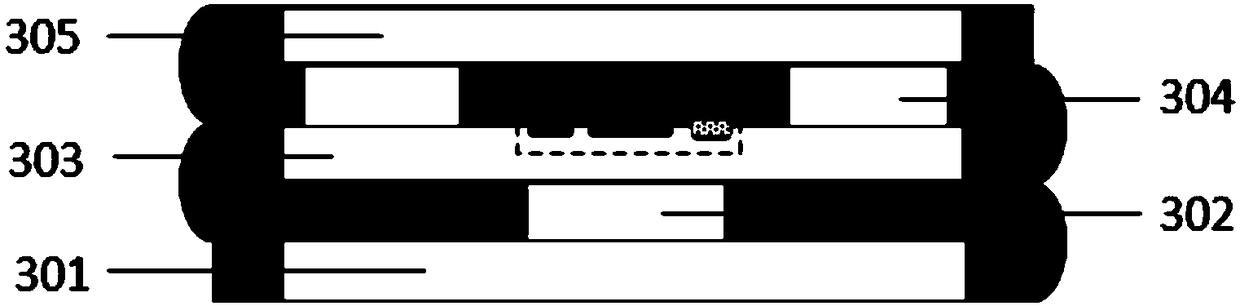

Folded paper-structured body surface sweat electrochemical sensor and monitoring method

ActiveCN109060923AAchieve flowReduce distractionsDiagnostic recording/measuringSensorsEngineeringContact layer

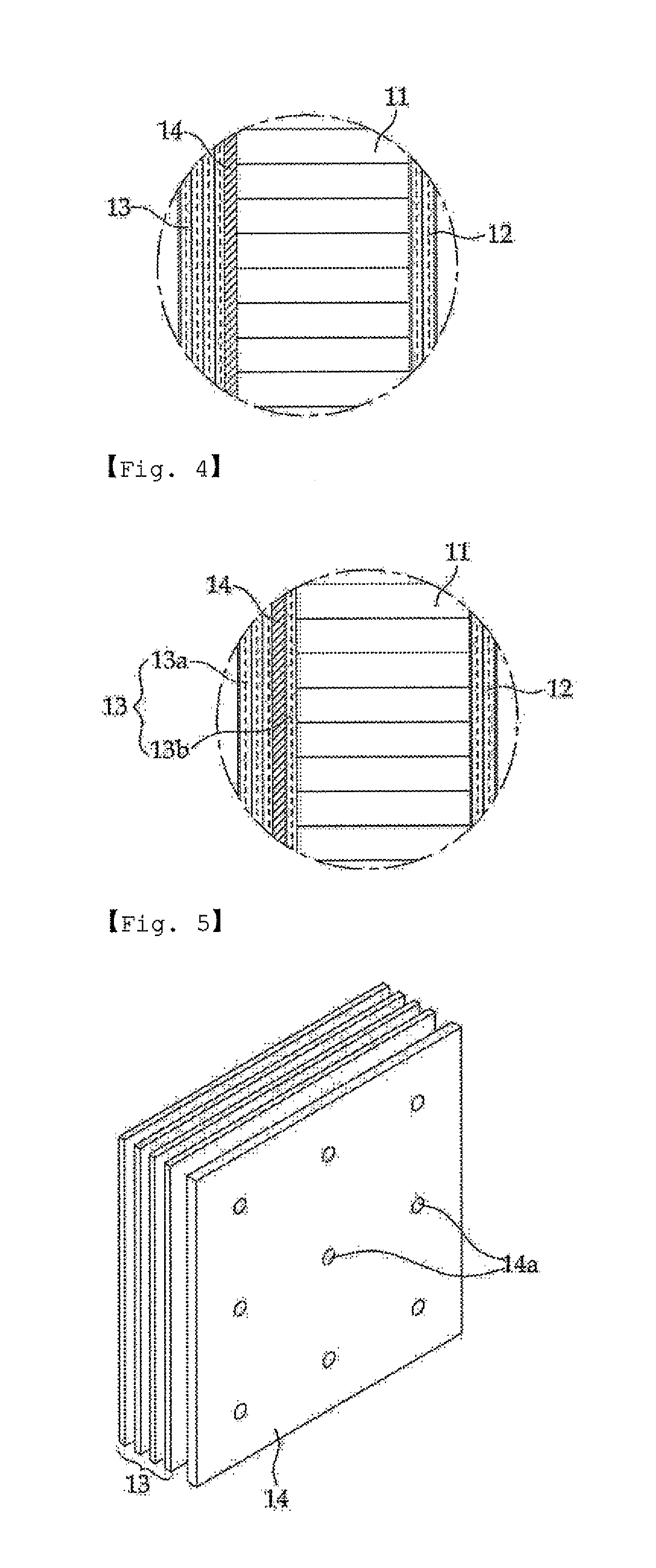

The invention discloses a folded paper-structured body surface sweat electrochemical sensor and a monitoring method, and relates to the electrochemical field. A paper substrate in the sensor is foldedto form 5 layers of paper structures; each layer of the paper structure is composed of a drainage layer and a hydrophilic layer; in the folding state, a first hydrophilic layer on a sweat collectinglayer, a second hydrophilic layer on a sweat diversion layer, a third hydrophilic layer on a sweat analyzing layer, a fourth hydrophilic layer on an electrode bearing layer, and a fifth hydrophilic layer on a sweat evaporating layer are contacted layer by layer to form a vertical channel, in which the sweat is diffused from the bottom of the sweat collecting layer to the top of the sweat evaporating layer; an electrochemical electrode system is set on one side of the electrode bearing layer folded towards the sweat analyzing layer; and an electrode detection end is contacted with the third hydrophilic layer on the sweat analyzing layer. The sensor and the monitoring method provided by the invention can separately collect, detect and evaporate the sweat, and reduce the mutual interference;the sweat is capable of flowing; the timeliness and the accuracy of the detection are improved; and at the same time, the discomfort of the user is reduced.

Owner:ZHEJIANG UNIV

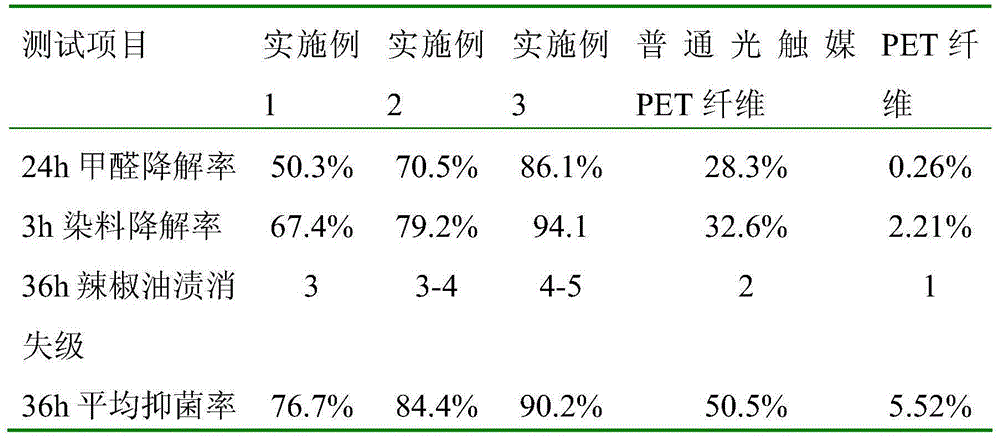

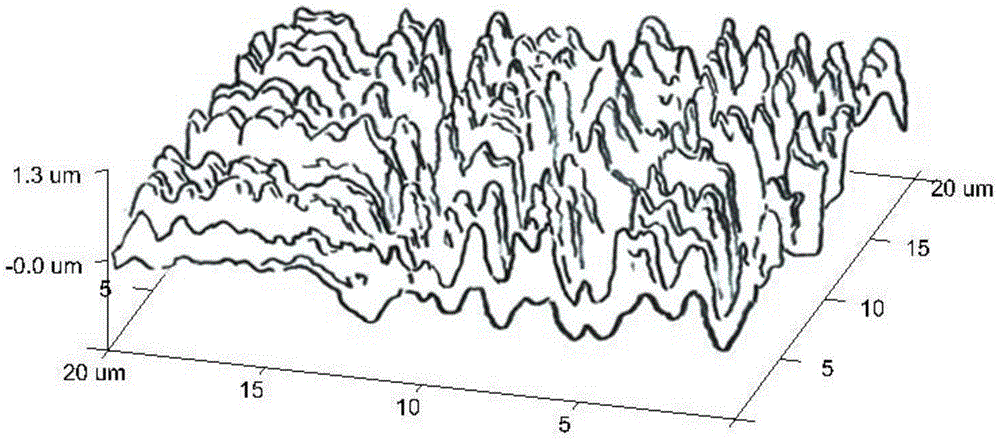

Preparation method of functionalized photocatalyst fibers

ActiveCN105019051AComplex processModerate costFilament/thread formingMonocomponent polyesters artificial filamentMelt spinningOxide

The invention discloses a preparation method of functionalized photocatalyst fibers. The preparation method comprises the following steps: (1) preparing functionalized nano TiO2 powder, namely, adding 5.0g of ferric trichloride and 3.0g of graphene oxide into 1000ml of nano TiO2 hydrosol, stirring at room temperature for 2 hours, cooling, filtering and baking to obtain the functionalized nano TiO2 powder; (2) preparing functionalized PET master batch, namely, uniformly mixing 15wt%-45wt% of functionalized nano TiO2 powder, 1.0wt%-2.0wt% of a polyethylene dispersant with relative molecular weight being 2000 and 53wt%-84wt% of PET sections in a high-speed mixer, performing melting extrusion at 180-240 DEG C, and performing water cooling, granulating and vacuum drying to obtain the functionalized PET master batch; and (3) spinning the functionalized photocatalyst fibers, namely, drying 20wt%-50wt% of master batch and 80wt%-50wt% of PET sections in vacuum for 1 hour, performing melt spinning on the dried product combined with skin cores at 280 DEG C, and stretching by 3-3.5 times, thereby obtaining the functionalized photocatalyst fibers.

Owner:TIANJIN POLYTECHNIC UNIV

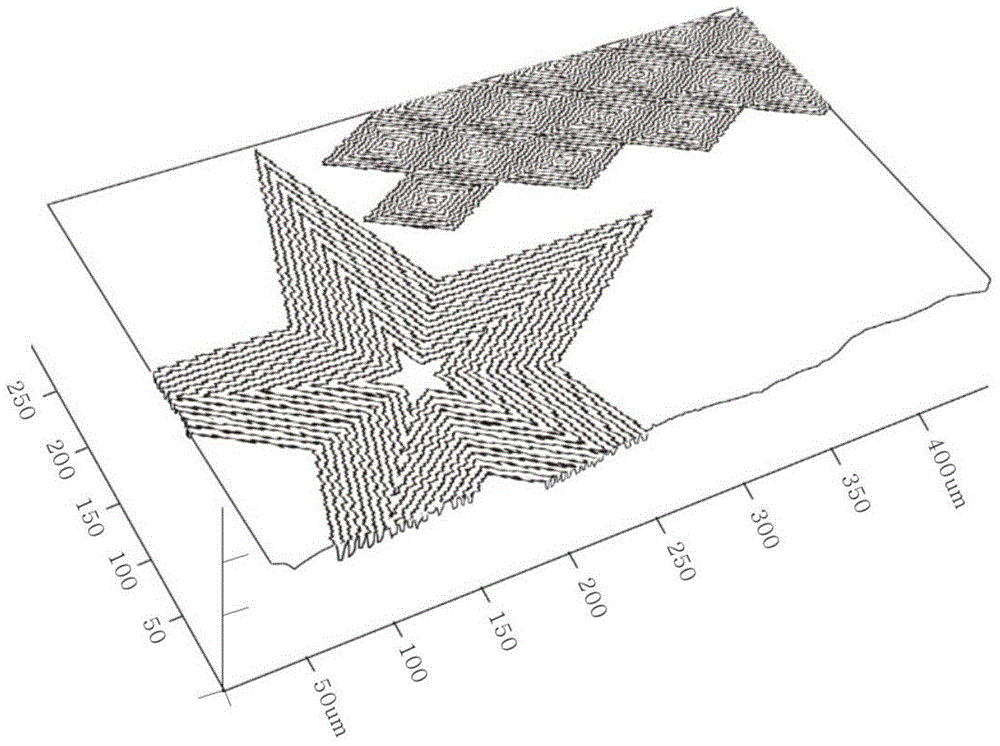

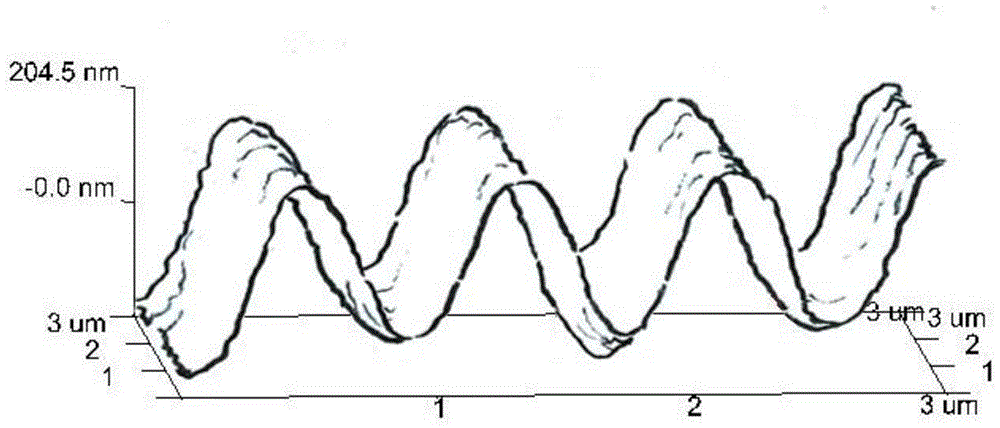

Manufacturing method of ink-free printing package

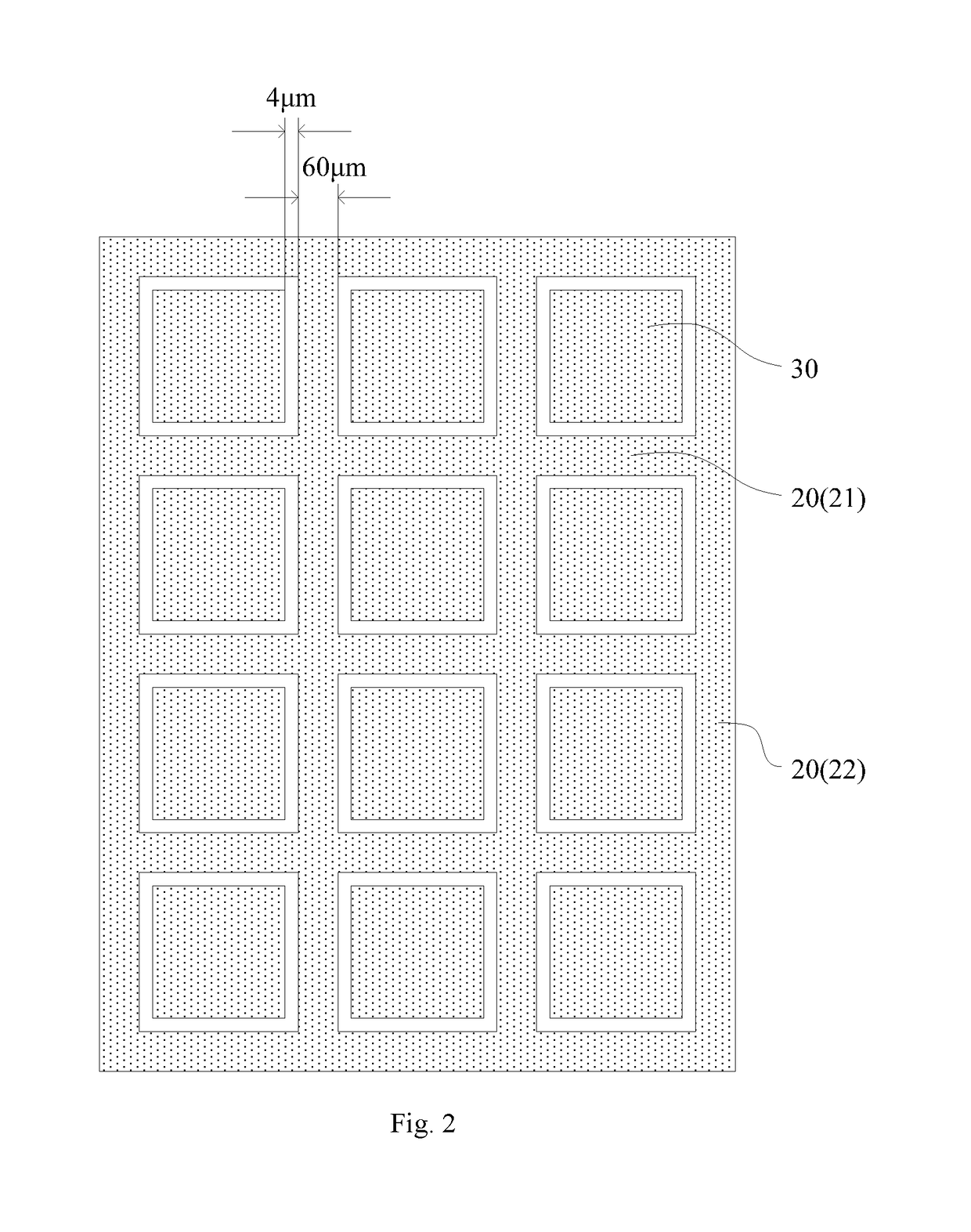

The invention relates to the fields of printing and packaging, in particular to a manufacturing method of an ink-free printing label or package. According to the structure, black and white display and color display of words and images are achieved by utilizing diffraction, scattering, reflection, refraction and the wave guide phenomenon of guide which are generated by a microstructure. The microstructure is characterized in that speckles at specific rules and lines with composite periods are displayed as black and white comparison when the frequency is 10 micrometers-150 micrometers, are displayed as color diffraction images when the regular period frequency is 0.3 micrometer-10 micrometers and are displayed as three-dimensional images when the irregular period frequency is 1 micrometer-2 micrometers. According to the method, graphics and text information is converted into the microstructure structure design to be expressed, the printing label or the package can be molded at a time through mould copying, so technological links are reduced, the cost is lowered, and environment protection and low carbon can be achieved better; a traditional oil printing package can be updated and replaced by the ink-free printing package, and the ink-free printing package has the advantages of being environmentally friendly, scientific, fashionable, safe and resistant to fake and the like.

Owner:SUZHOU IMAGE LASER TECH

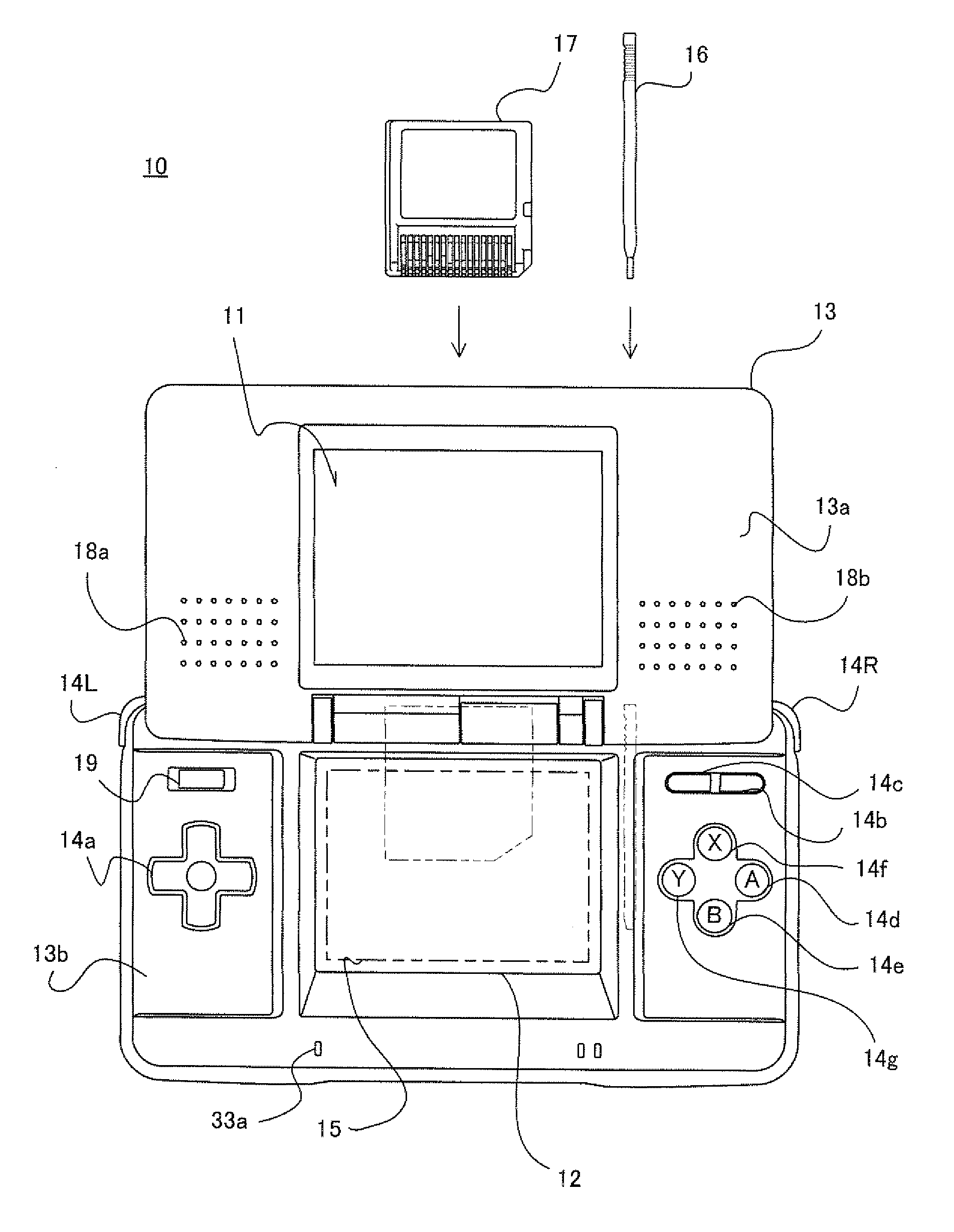

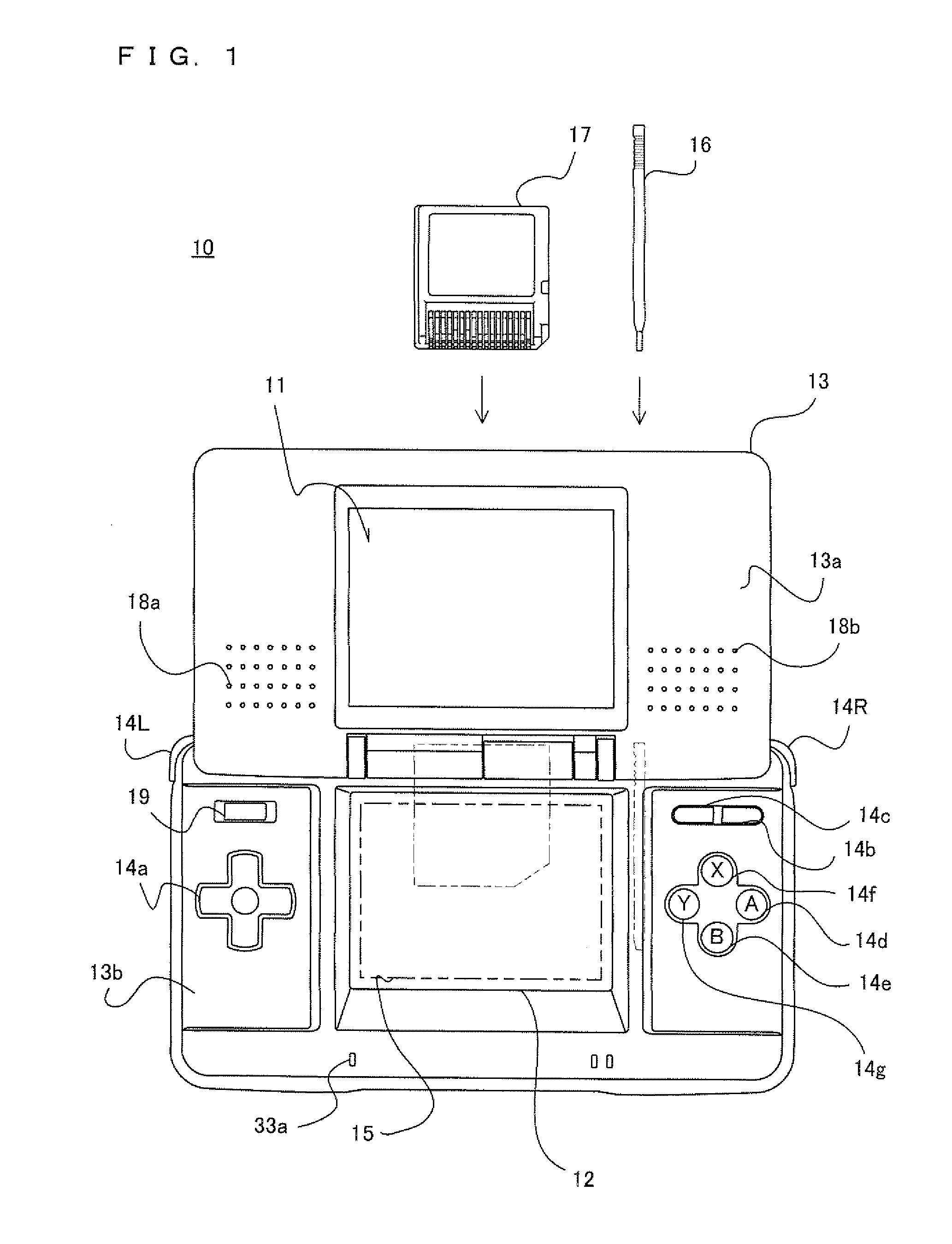

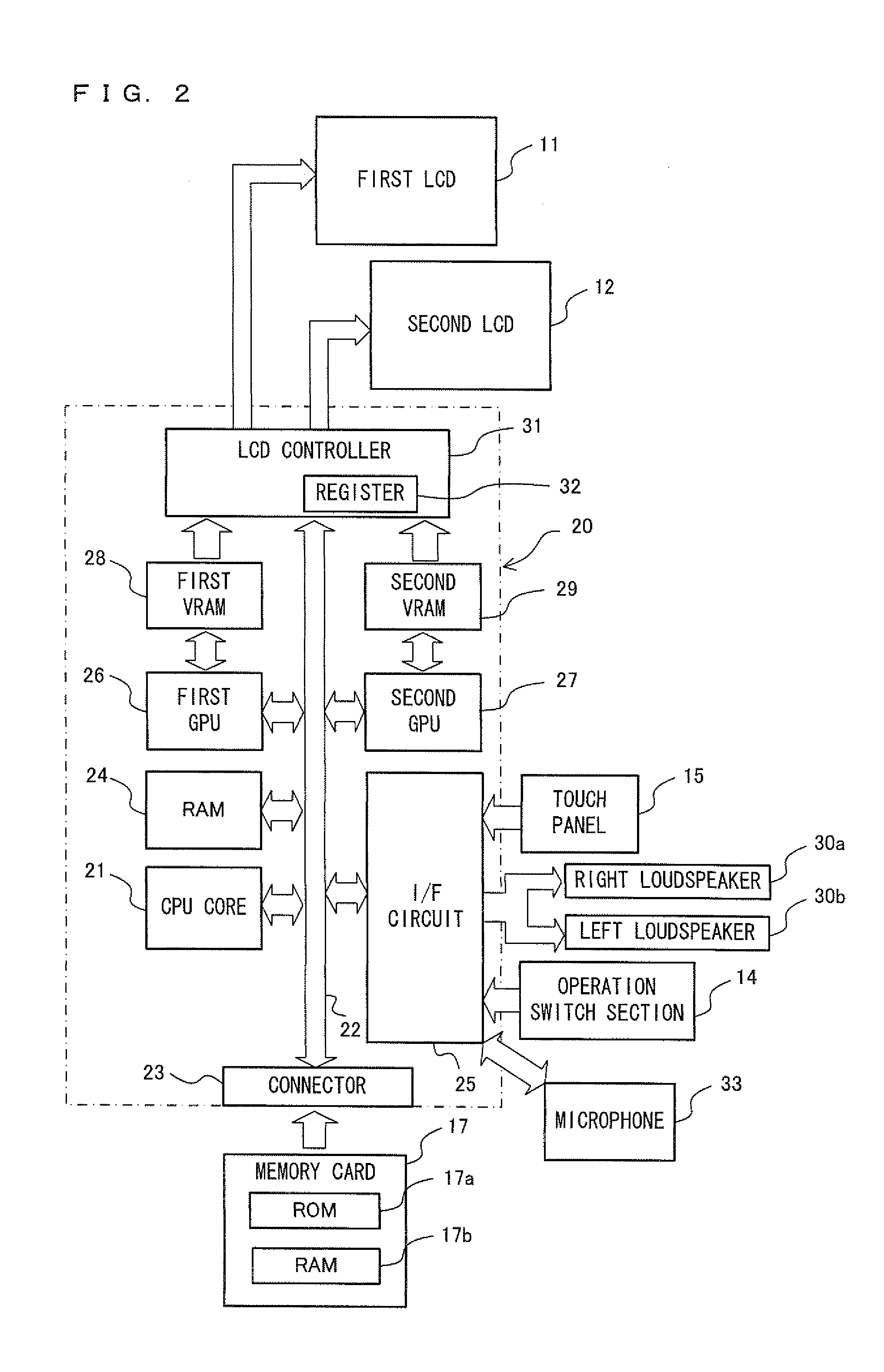

Computer-readable storage medium storing game program, and game apparatus

InactiveUS20090163282A1Complex processMore complex processingVideo gamesSpecial data processing applicationsHuman–computer interaction

A game apparatus detects an input position, on an input plane, at which an input operation has been performed. The game apparatus also detects an operation sound that occurs due to the input operation performed on the input plane. The game apparatus evaluates the detected operation sound, and obtains a result of the evaluation (e.g., volume of the operation sound). The game apparatus performs game processing by using the detected input position and the result of the evaluation. This enables the game apparatus to perform more complex processing by using a touch operation as input information, and allows a player to provide more complex instructions based on the touch operation.

Owner:NINTENDO CO LTD

Method for preparing non-ionic calcium stearate water-based dispersion emulsion

InactiveCN102210994AHigh viscosityLow viscosityTransportation and packagingMixingWater basedStearic acid

The invention belongs to the chemical field and in particular relates to a method for preparing non-ionic calcium stearate water-based dispersion emulsion. The method provided by the invention comprises the following steps of: adding water, stearic acid, emulsifier A, emulsifier B, emulsification assistant, protective colloid aqueous solution, defoaming agent, bactericide and electrolyte salt in a container in certain proportion; then heating until the temperature is increased to 85 DEG C, rapidly stirring and emulsifying, reducing the stirring speed after emulsifying at constant temperature for 1 hour, slowly adding alkalizer in certain proportion, stirring at constant temperature for 3 hours, and then rapidly cooling to room temperature, thus a target product is obtained. The water phase emulsion reaction method provided by the invention has the advantages of simple process, low cost, high solid content, low viscosity, good stability, no yellowing, no objectionable odour and no pollution, and the particle size of calcium stearate and the solid content and viscosity of the water-based dispersion emulsion are adjustable in a certain scope.

Owner:HUNAN UNIV OF SCI & TECH

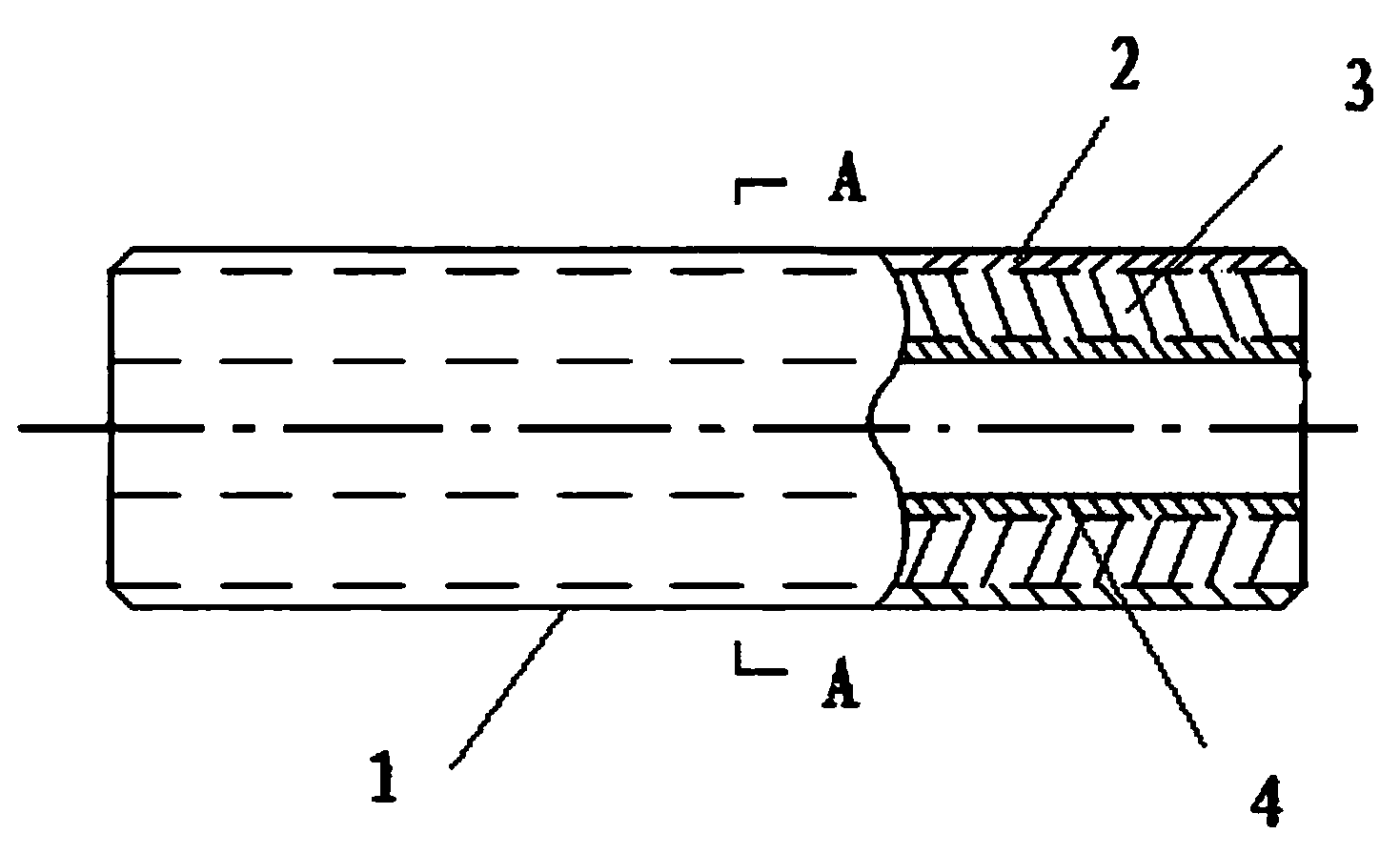

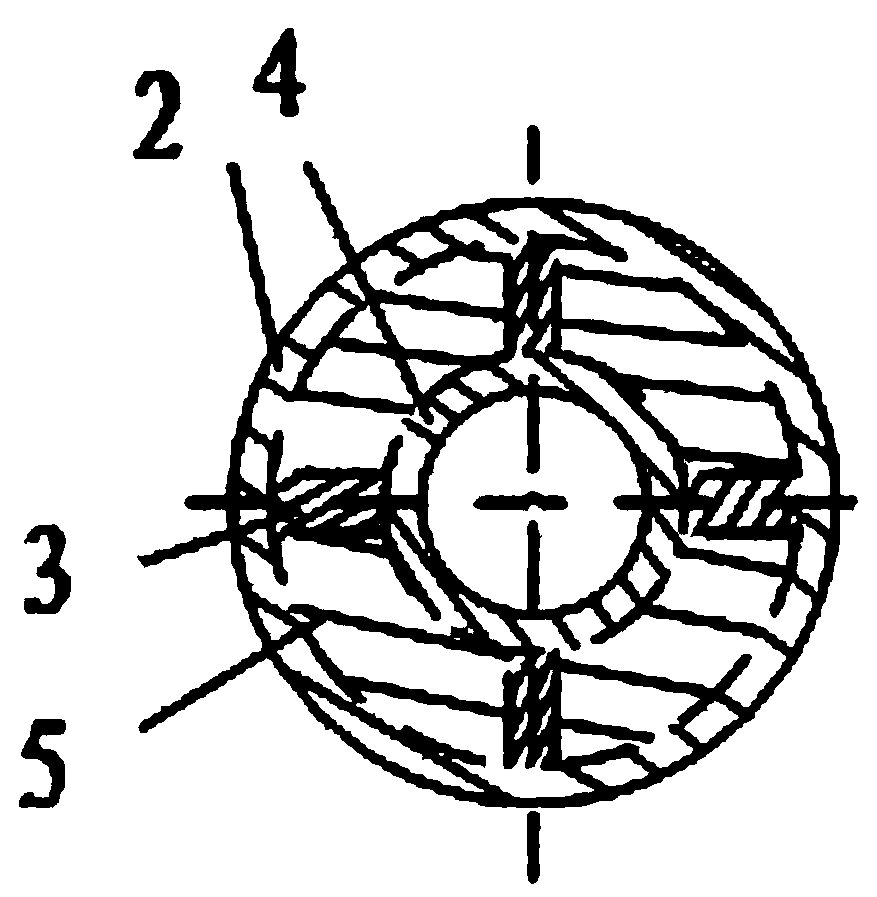

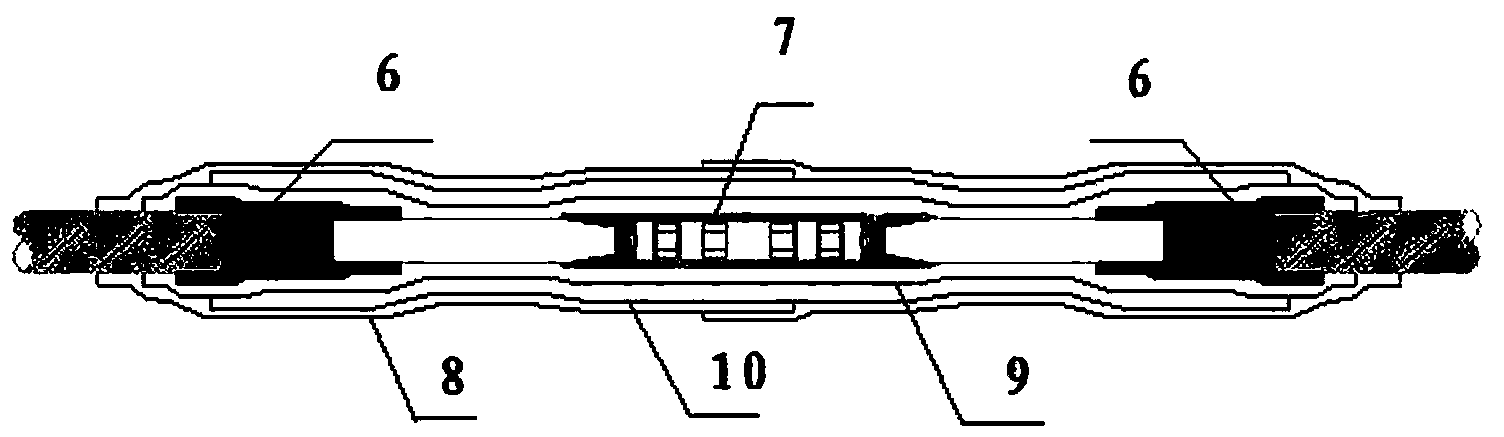

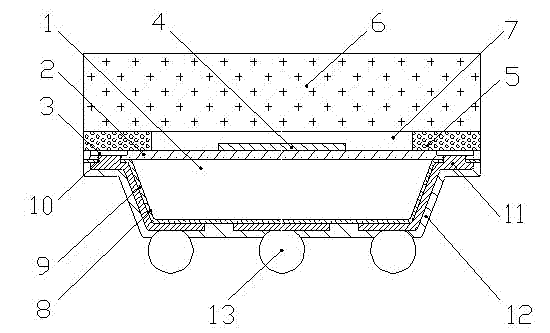

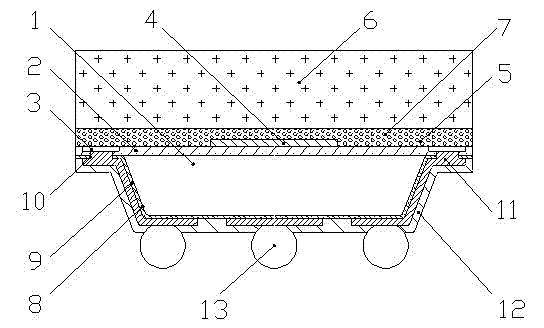

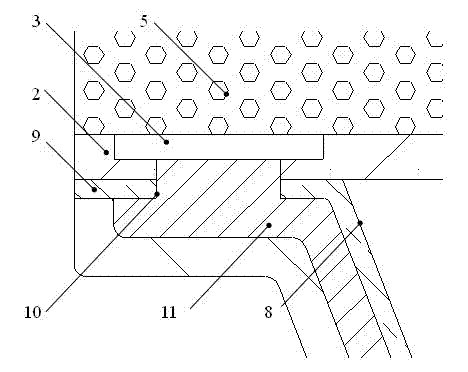

Middle joint connection tube of phase-change temperature-control type high-voltage cable

InactiveCN104037717AAvoid damageImprove thermal shock resistanceCable junctionsEngineeringHigh pressure

The invention discloses a middle joint connection tube of a phase-change temperature-control type high-voltage cable, and relates to the technical field of high-voltage cable connection. The tube comprises a tube body, the tube body is divided into an inner tube main body and an outer tube main body, filler is arranged between the inner tube main body and the outer tube main body, and the filler comprises a composite phase-change material. By means of the phase-change temperature-control function of the organic composite phase-change material, the temperature of a cable joint is lowered through the connection tube, the thermal aging process of the cable joint is controlled, the fault that the cable joint is too hot caused due to impact load and the like is avoided, and the service life of the cable is prolonged.

Owner:STATE GRID CORP OF CHINA +1

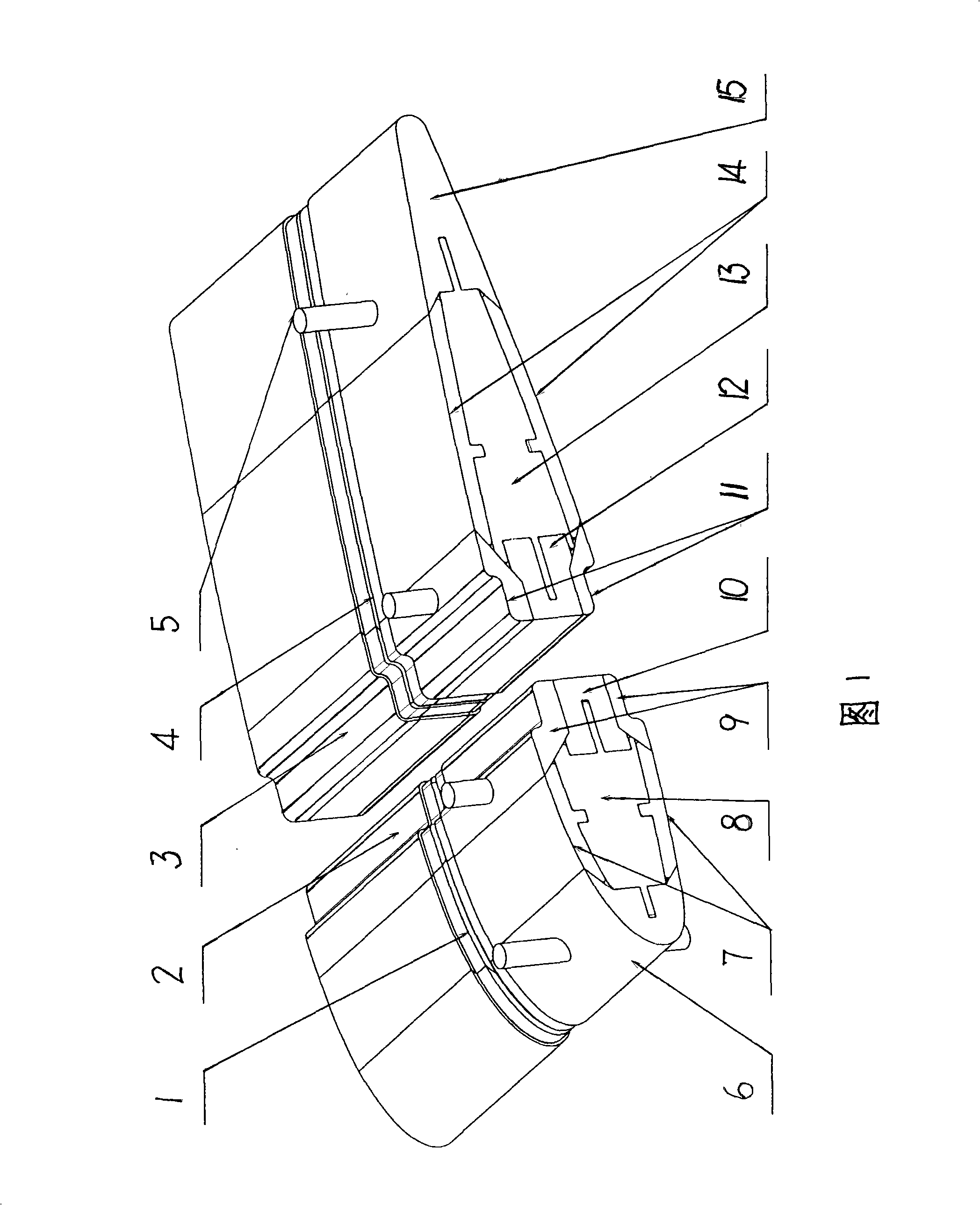

Disposal solidifying and forming technique for frame and outer panel skin of wing profile

InactiveCN101342942AIncrease stiffnessHigh strengthFuselage bulkheadsAircraft assemblyFiberEngineering

The invention provides a technique for curing and molding an airfoil frame and an aircraft skin at one time. The technique adopts built-in detachable grouped dies; the dies are transversely divided into different die groups by carlings, and each die group is composed of a set of module and a central slideway; the module and the central slideway in each group can slide relatively and can be taken out from the die cavity sequentially; all the bulkheads and the carlings are provided with concave grooves which match with the airfoil frame in shape; the ventral shields of the airfoil carlings are the combination of composite material and I-shaped alloy plates; bulkhead fibre is laid inside the concave grooves through winding. After the frame fiber is laid, the skin fibre is uniformly laid, forming a hatch rim frame the same as the bulkheads; after that, a vacuum bag is arranged at the outer surface and grease injection and vacuum die press molding are adopted; the frame and the aircraft skin are molded and cured at one time through the technique of electron beam heating, high temperature stove heating or curing at normal temperature according the compounding technological requirements of the fibre resin substrate. The invention has fewer accessories, lighter weight, short production period, low cost and high safety factor and the anti-corrosion capability and anti-fatigue capability are improved by more than two times.

Owner:马献林 +1

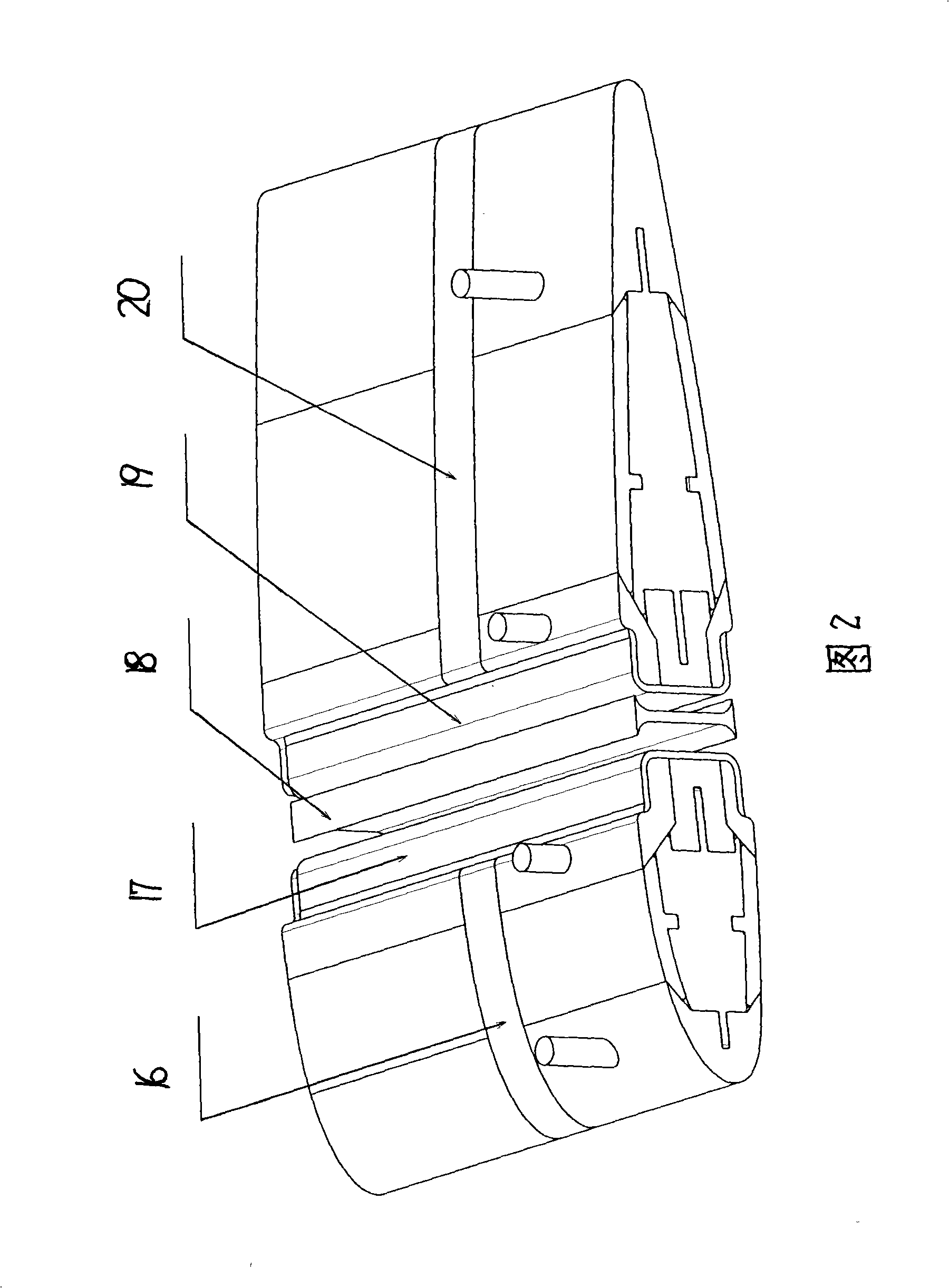

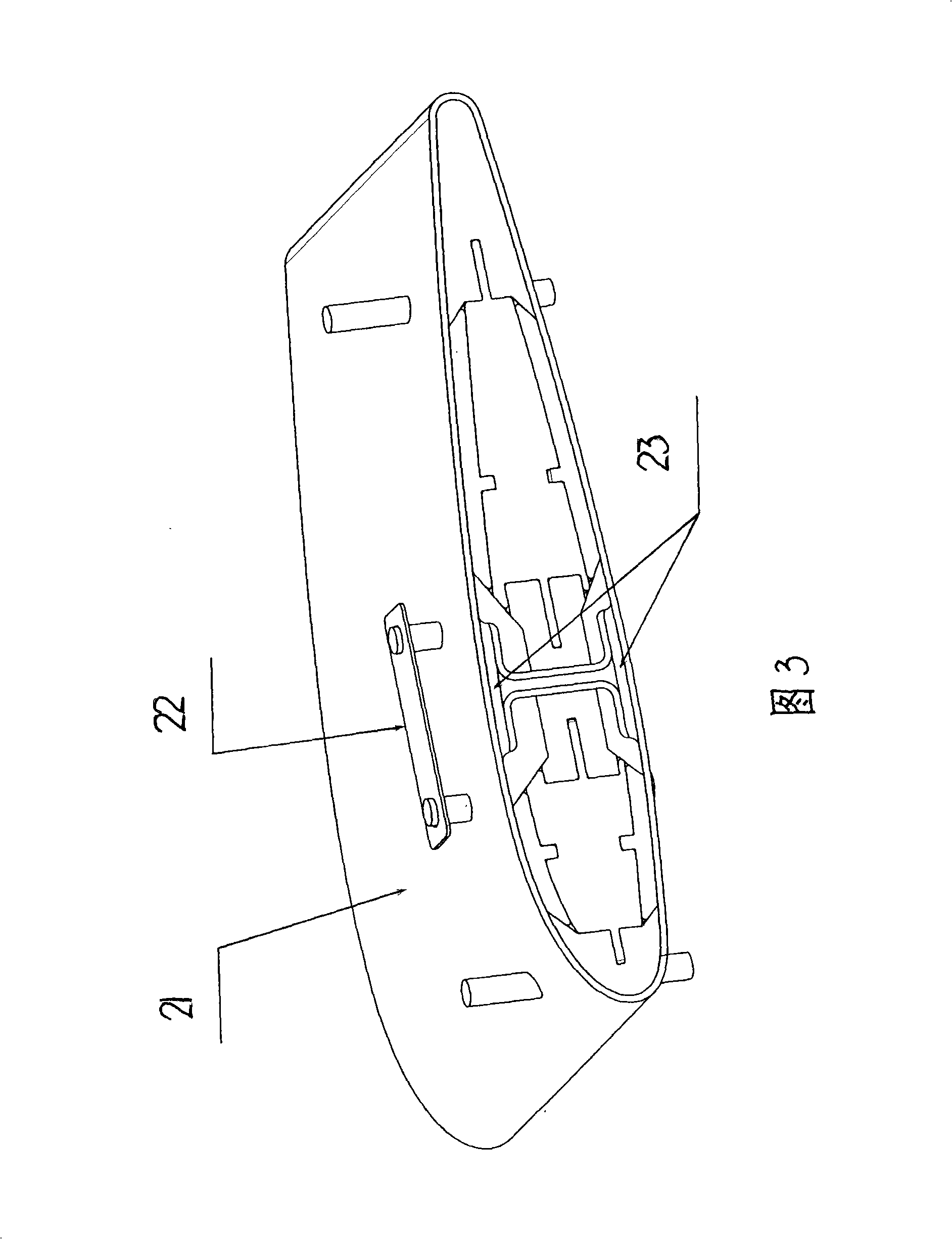

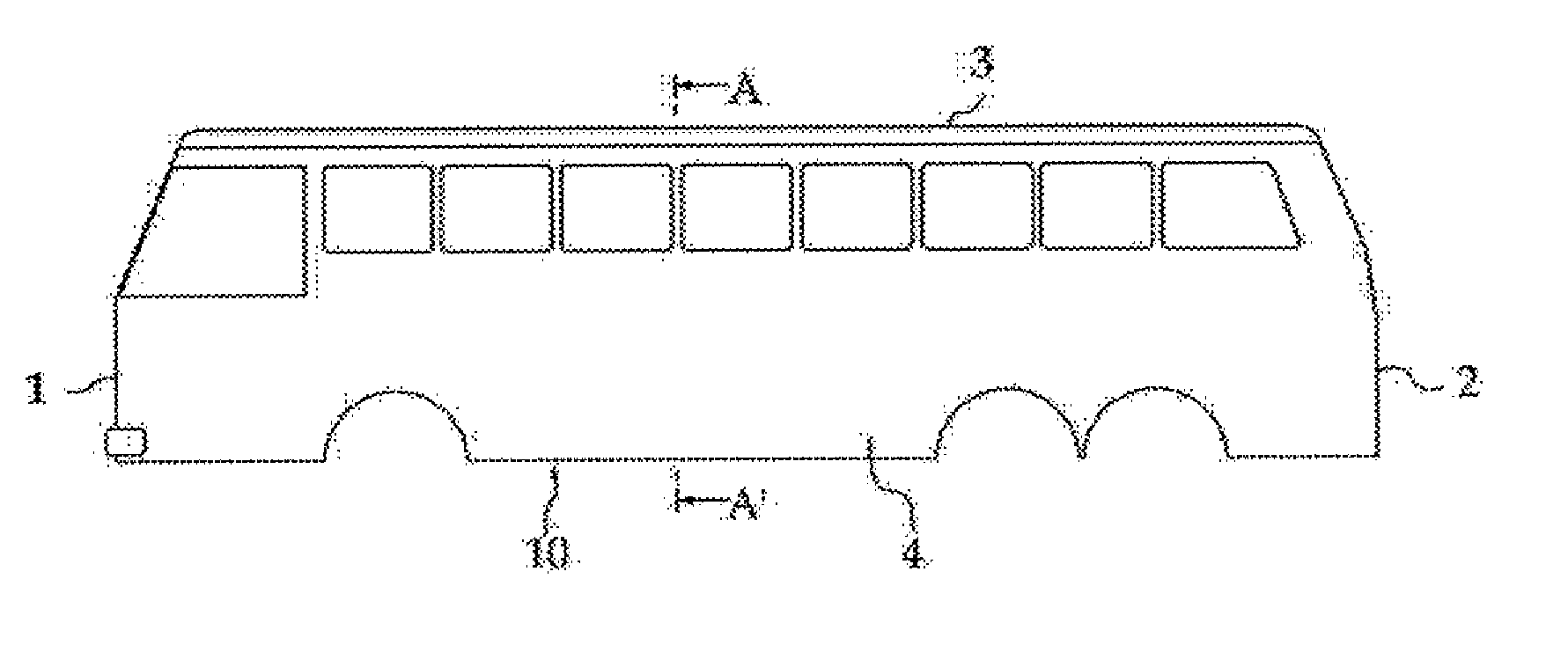

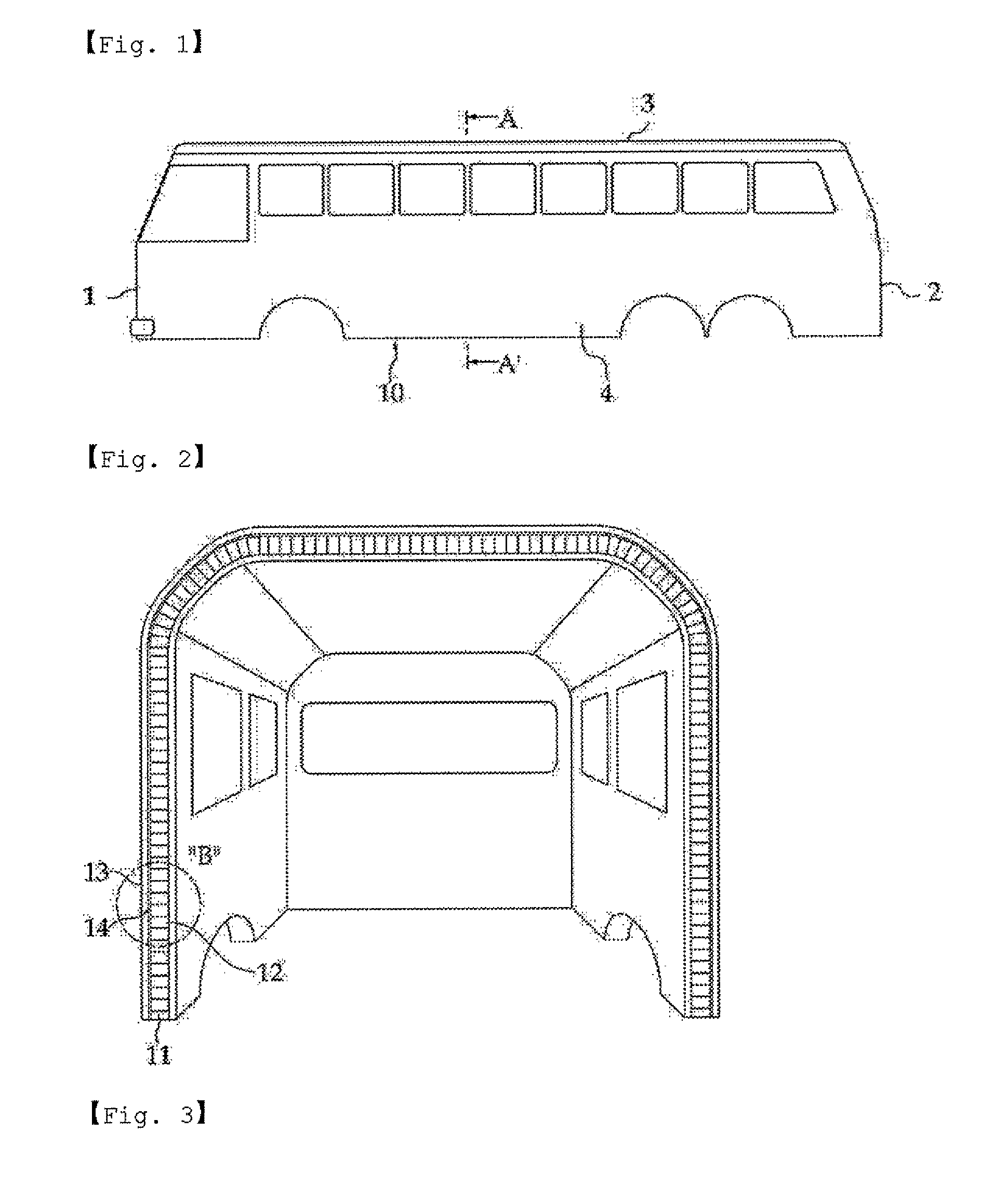

Integrated Composite-Material Vehicle Body for a Transportation Vehicle, and a Production Method Therefor

InactiveUS20100140975A1Complex processEnhance brittleness and fatigue characteristicVehicle seatsWindowsAutomotive engineeringSandwich panel

The present invention relates to a vehicle body formed by a simultaneous curing method using a composite material, and to a production method therefor. An integrated composite-material vehicle body for a transport vehicle obtained by integral forming in the shape of the vehicle body and using a sandwich panel including: a core material; an inner skin material which is made using a prepreg of reinforcing fibres impregnated with a synthetic resin and semi-cured, and which is adhered to the inside surface of the core material; an outer skin material which is made using a prepreg of reinforcing fibres impregnated with synthetic resin and semi-cured, and which is adhered to the outside surface of the core material; and a sheet metal material which is inserted between the core material and the outer skin material.

Owner:HUN KUK FIBER GLASS CO LTD

Switch unit and game machine

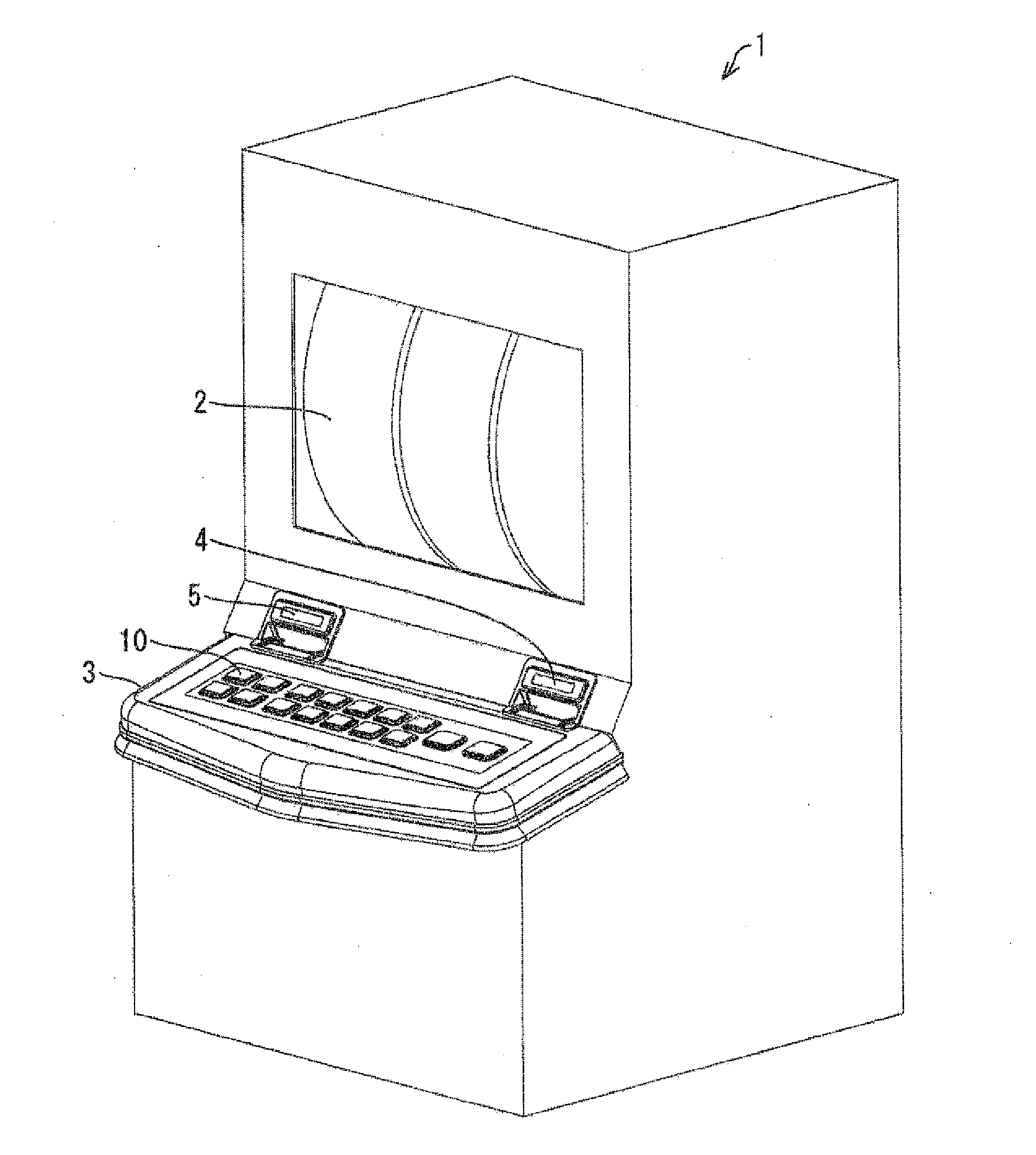

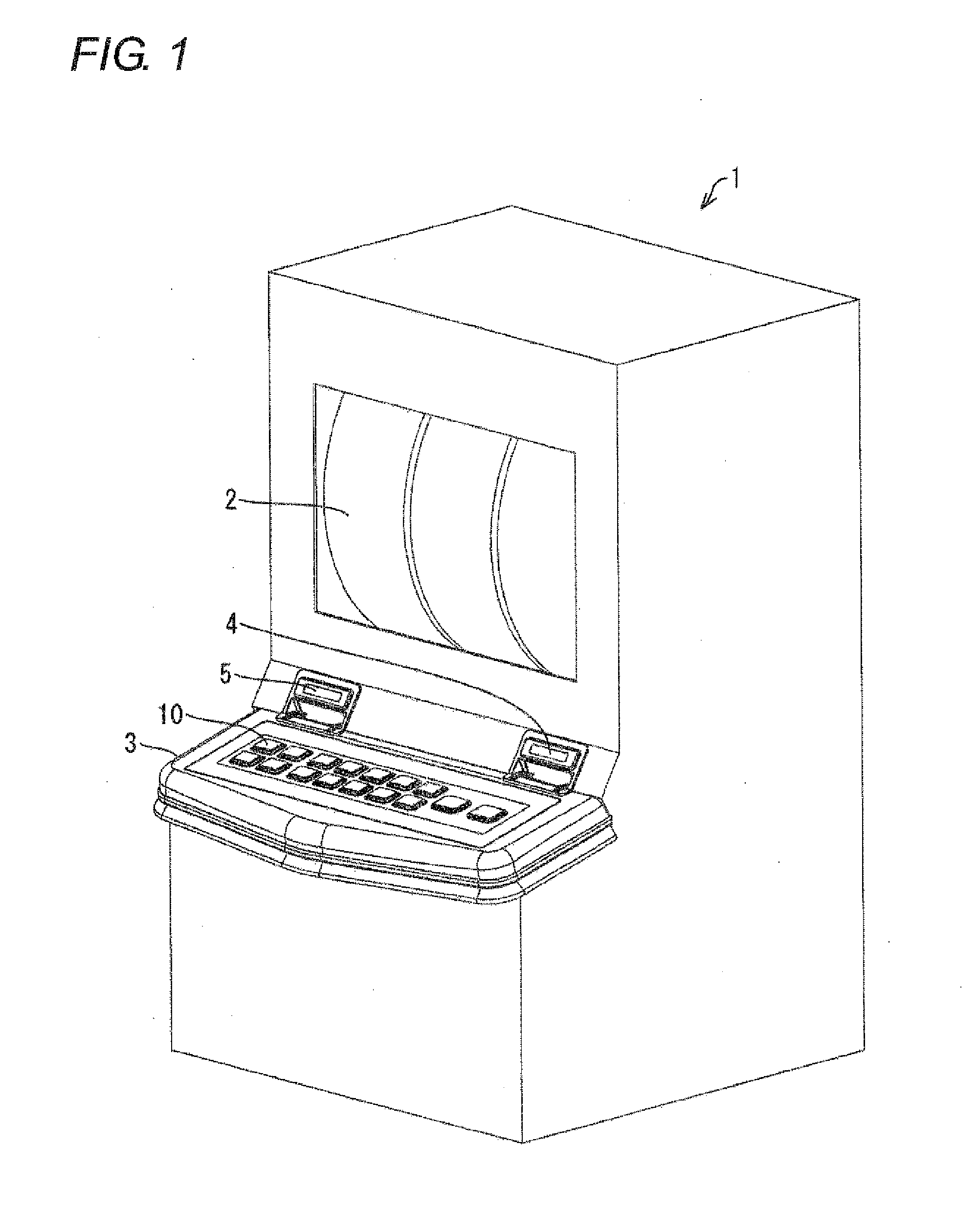

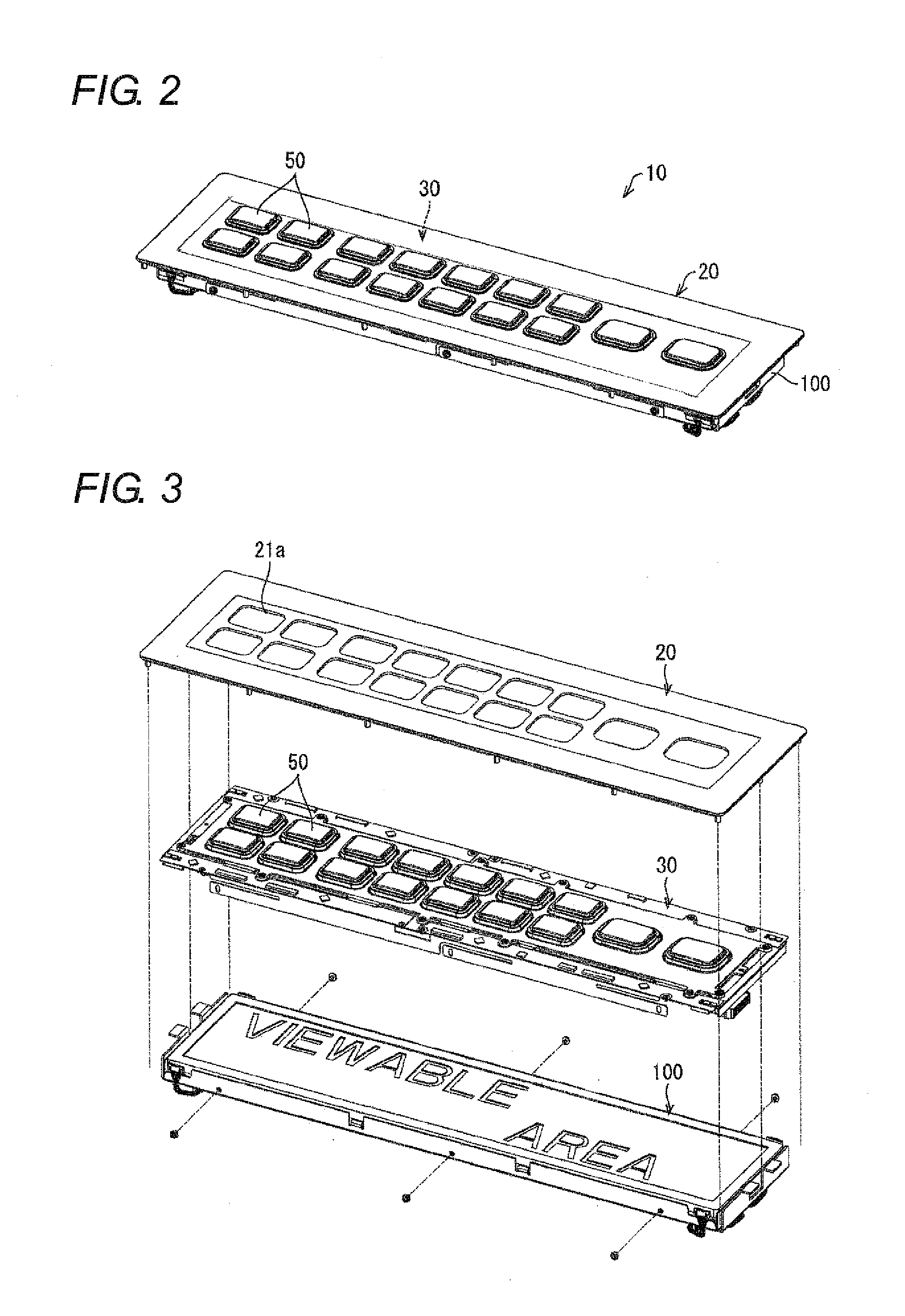

ActiveUS20160335845A1Big impactComplex processMechanical apparatusPoint-like light sourceEngineeringFlange

A switch unit has a display part configured to display an image, and an operation part provided on the display part in a stacked manner. The operation part includes a plurality of press buttons each having a pressable top surface formed to be transparent, a transparent base having a plurality of openings formed so as to be spaced from each other in positions corresponding to a display region of the display part, while avoiding a peripheral edge of the display region, and a transparent substrate provided below the base and having a light source in a position corresponding to the outer periphery of the top surface. Each of the press buttons includes, and forms into a unit, a button body having the top surface, and a frame-like light guiding body provided in a flange shape below the button body and provided so as to cover the light source.

Owner:ORMON CORP

Method for extracting and separating L-lactic acid from ammonium lactate fermentation material liquid

ActiveCN104557515ASpecific adsorptionAchieve purificationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationSpecific adsorptionCoupling

The invention discloses a method for extracting and separating L-lactic acid from an ammonium lactate fermentation material liquid. The method comprises the following steps: (1) pre-treating the ammonium lactate fermentation material liquid; (2) carrying out sulphuric acidolysis on ammonium lactate; (3) adding an acidolysis material liquid and a coupling adsorbent in a centrifugal extractor respectively, and extracting L-lactic acid through coupling adsorption at 15-25 DEG C; (4) separating an organic phase from a water phase; and (5) adding the organic phase and hot water at 55-65 DEG C in the centrifugal extractor respectively, and extracting L-lactic acid through backcoupling adsorption. The method disclosed by the invention is capable of rapidly extracting and separating L-lactic acid from the lactic acid acidolysis liquid, changing the process route of separating various impurities from L-lactic acid one by one, and directly separating L-lactic acid through coupling adsorption by virtue of a coupling adsorption agent so as to leave the various impurities in a raffinate; because the coupling adsorption agent in the method disclosed by the invention has a specific adsorption property on L-lactic acid, the purpose of further purifying L-lactic acid is achieved, and a decolouring process and most of hybridization processes in the existing processes are removed.

Owner:河南金丹乳酸科技股份有限公司

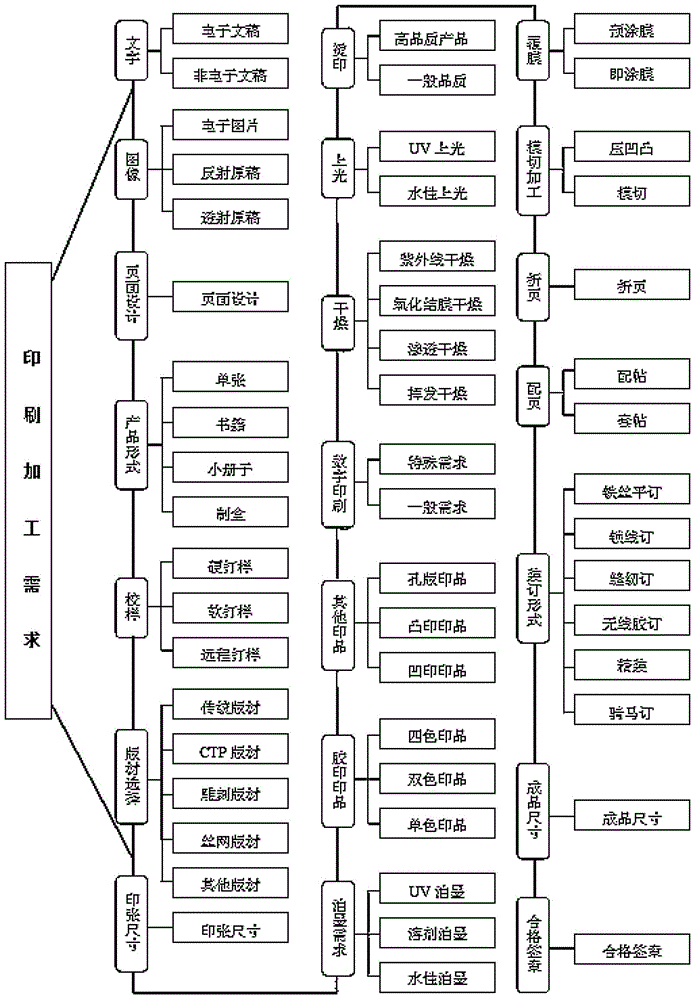

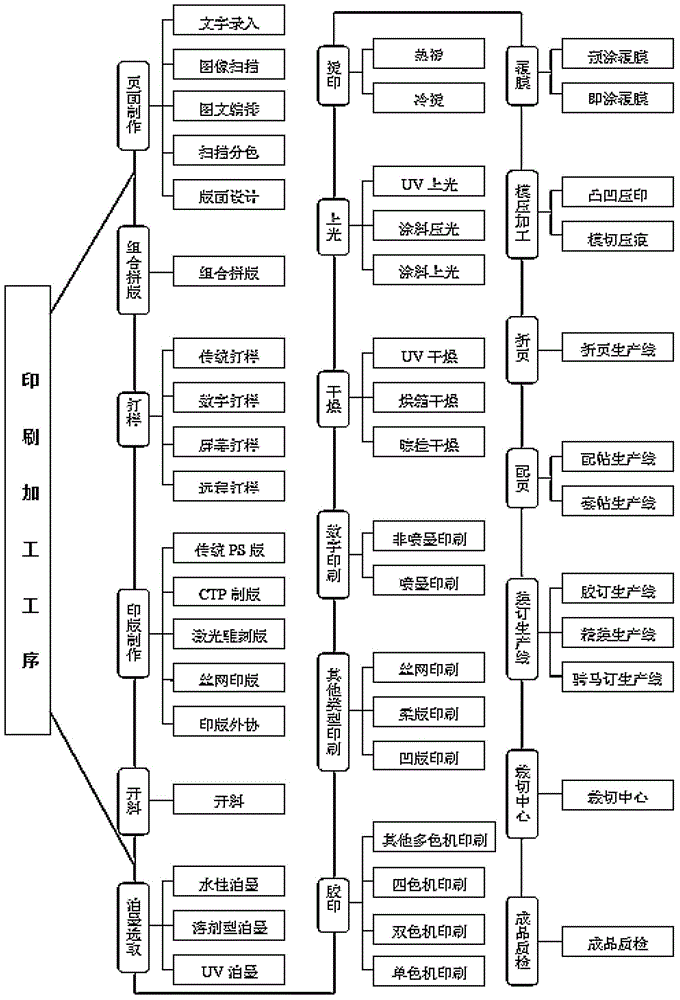

Printing method based on multi-color integration theory

The invention discloses a printing method based on a multi-color integration theory. The printing method comprises the steps of building a printing processing requirement model and a printing processing working procedure model, building a contour matrix of process groups, extracting process groups of required printing processing working procedures, building a contour matrix meeting printing processing requirements and conforming to corresponding working procedures, extracting a required technical operator, calculating an interchange working procedure, calculating a required technical path and printing, thus completing the printing of an object to be printed. In a mode of layering the printing requirement model and the printing processing model, the required technical operator is simply and quickly screened out, and the problems of complicated process, large working amount and redundant calculation amount of conventional printing methods are solved.

Owner:广东潮华龙印刷有限公司

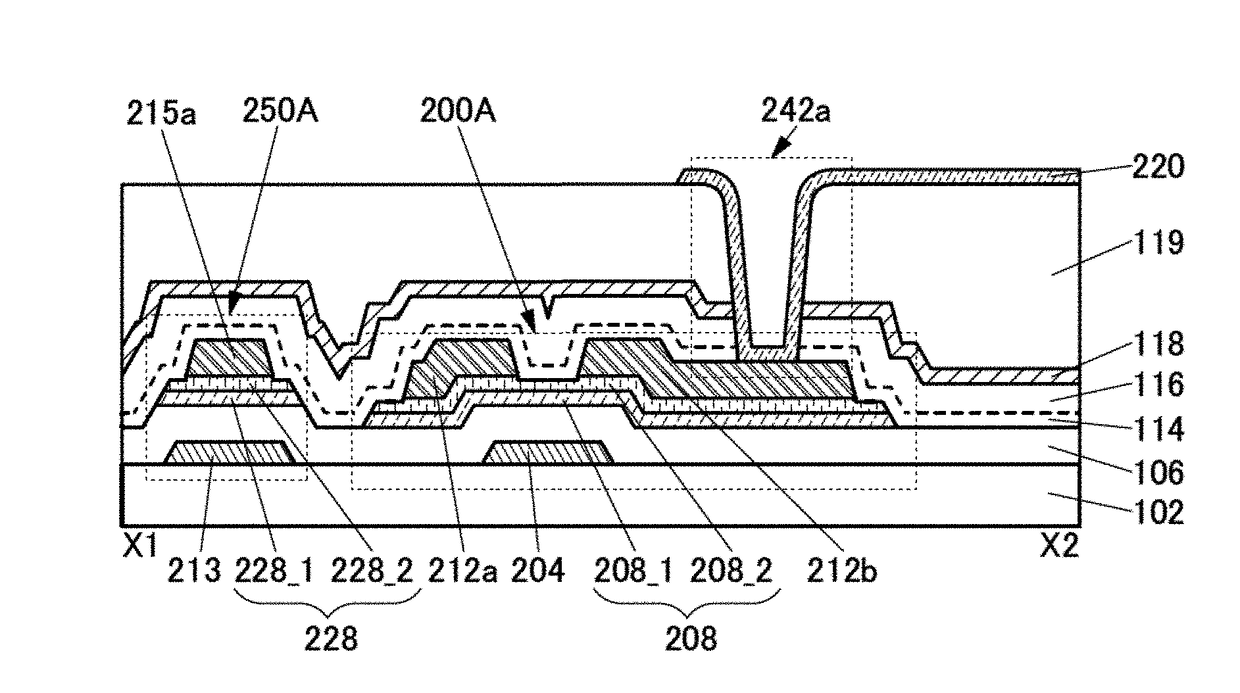

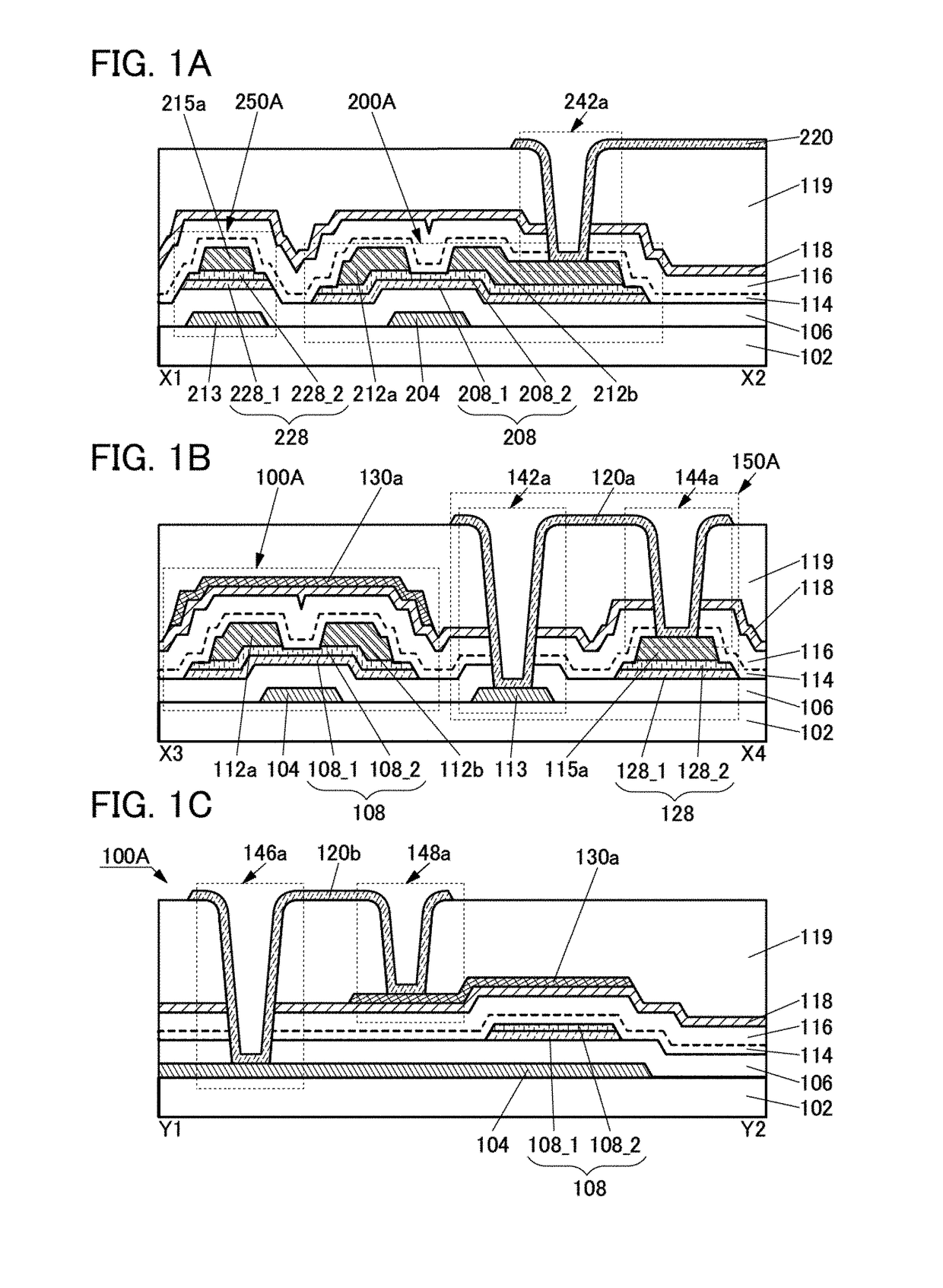

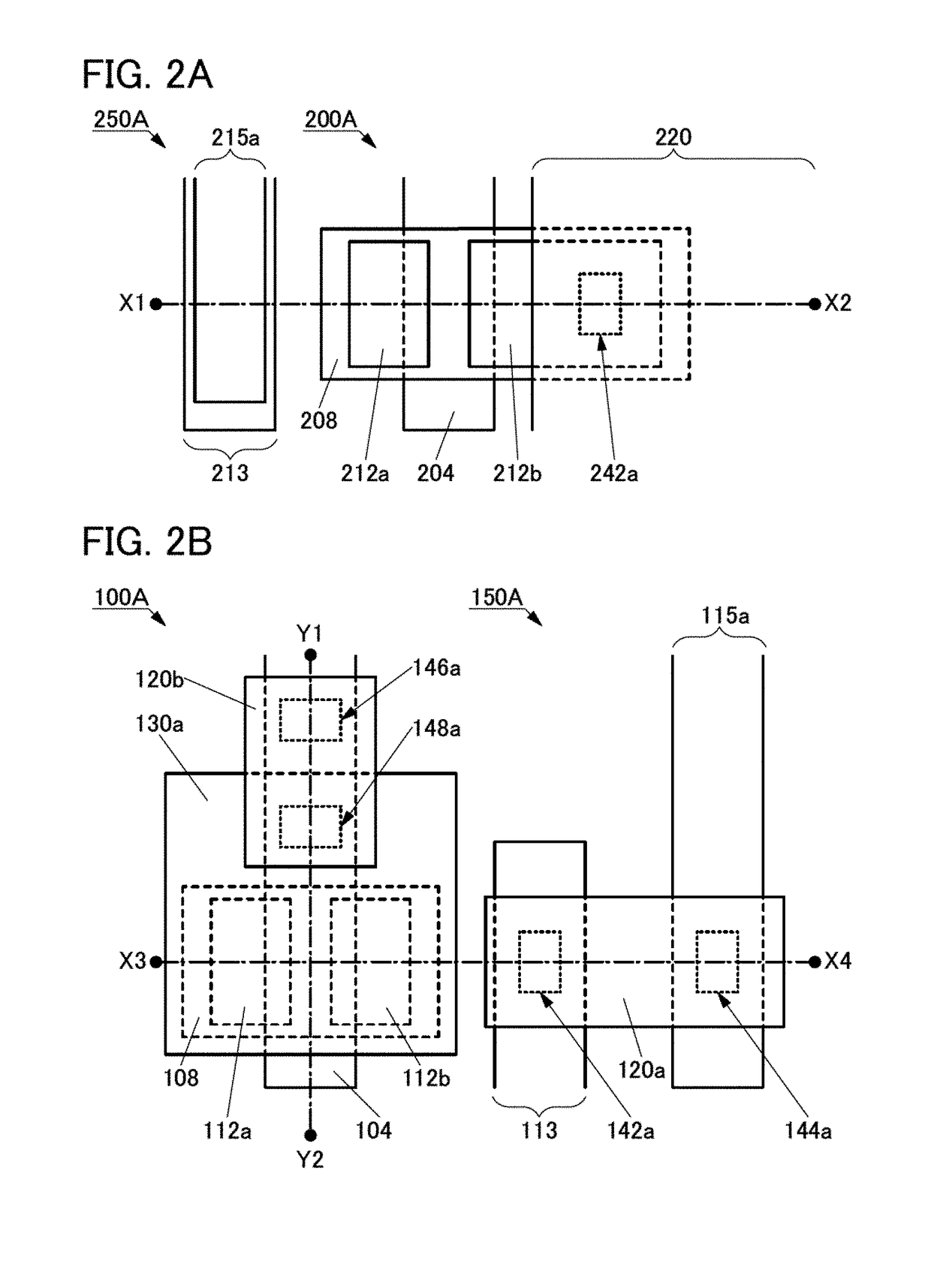

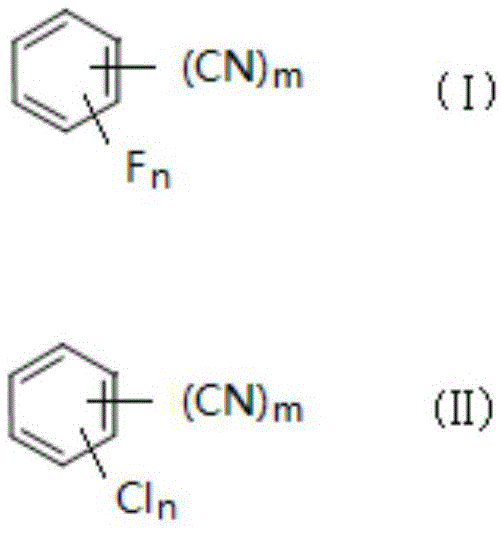

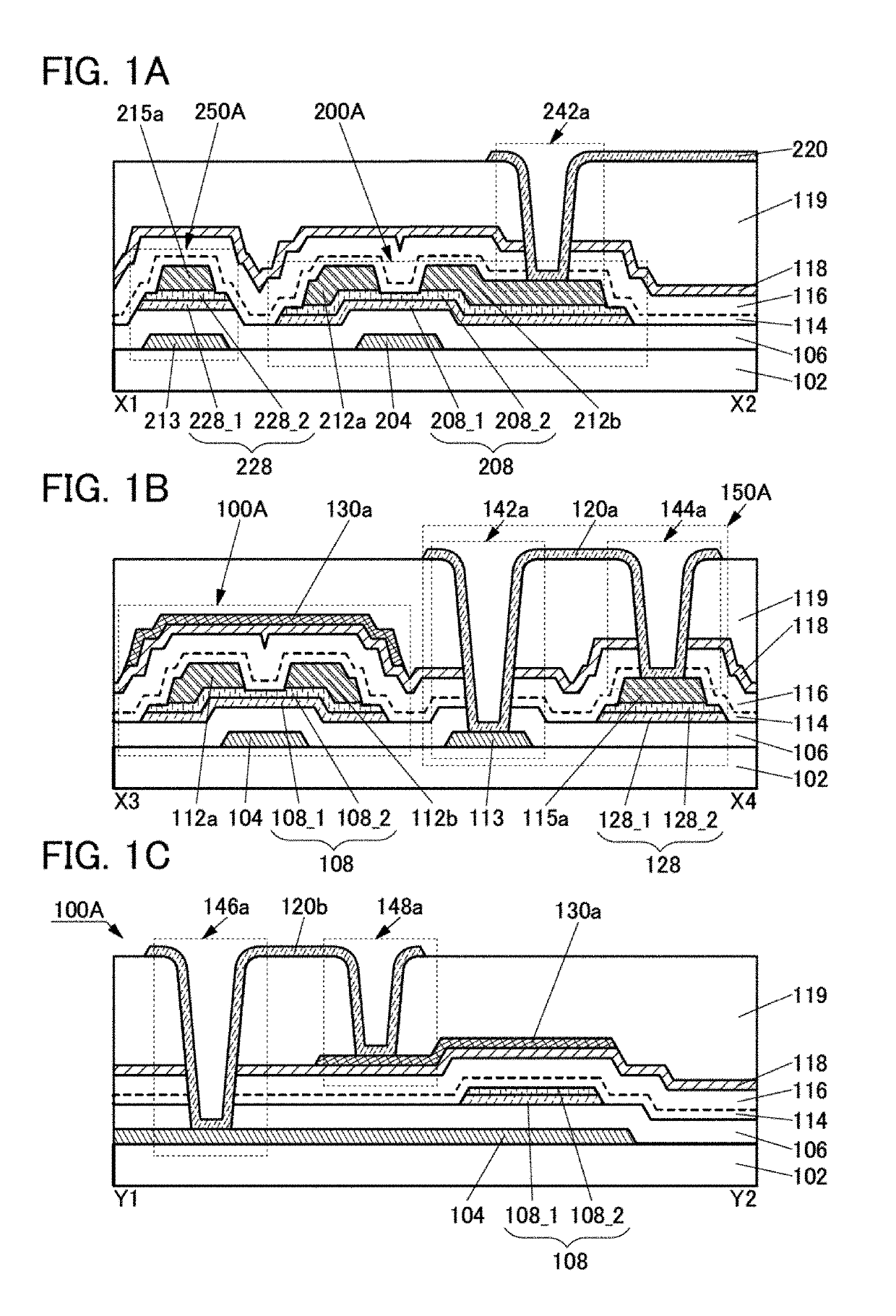

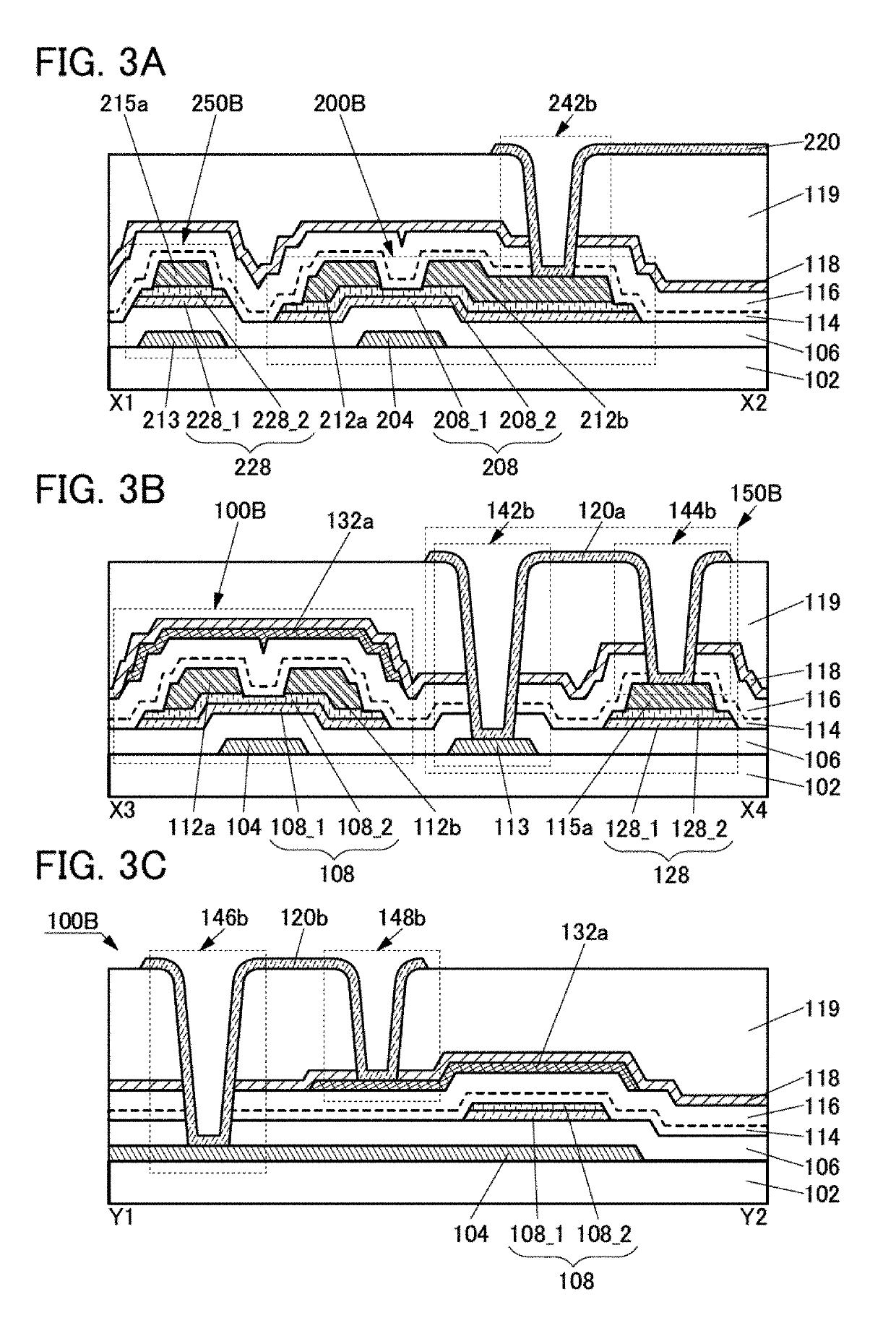

Display device and electronic device

ActiveUS20180102086A1High alignment accuracyReduction in yieldTransistorStatic indicating devicesLithography processHigh definition

The number of lithography processes is reduced and a high-definition display device is provided. The display device includes a pixel portion and a driver circuit for driving the pixel portion. The pixel portion includes a first transistor and a pixel electrode electrically connected to the first transistor. The driver circuit includes a second transistor and a connection portion. The second transistor includes a metal oxide film, first and second gate electrodes that face each other with the metal oxide film positioned therebetween, source and drain electrodes over and in contact with the metal oxide film, and a first wiring connecting the first and second gate electrodes. The connection portion includes a second wiring on the same surface as the first gate electrode, a third wiring on the same surface as the source electrode and the drain electrode, and a fourth wiring connecting the second wiring and the third wiring. The pixel electrode, the first wiring, and the fourth wiring are formed using the same layer.

Owner:SEMICON ENERGY LAB CO LTD

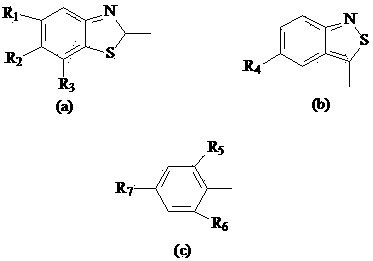

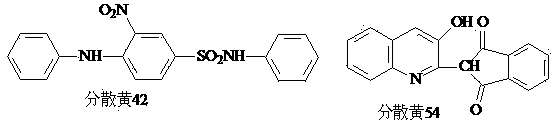

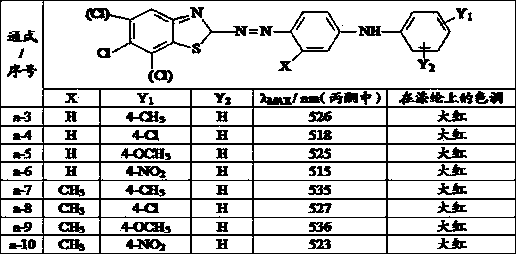

Diaminoazobenzene type disperse dye and application thereof

ActiveCN103525121AChromatography is completeImprove dye uptakeOrganic dyesDyeing processDisperse dyeCellulose fiber

The invention discloses a diaminoazobenzene type disperse dye with a general formula (1) as shown in the specification. The diaminoazobenzene type disperse dye has the characteristics of bright shade, excellent dyeing performance and fastnesses and wide pH range. The diaminoazobenzene type disperse dye can be used for performing pretreatment and one-step one-bath dyeing on polyester, polyester superfine fibers and a blend fabric of polyester and cellulose fibers in a strong alkaline bath, performing same-pulp printing on a disperse / active dye of the blend fabric of polyester fibers and cellulose fibers, and performing one-step method alkaline burn-out printing on double-sided plush, non-inverted velvet and super-soft short floss type polyester fabrics.

Owner:JIANGSU YABANG DYE

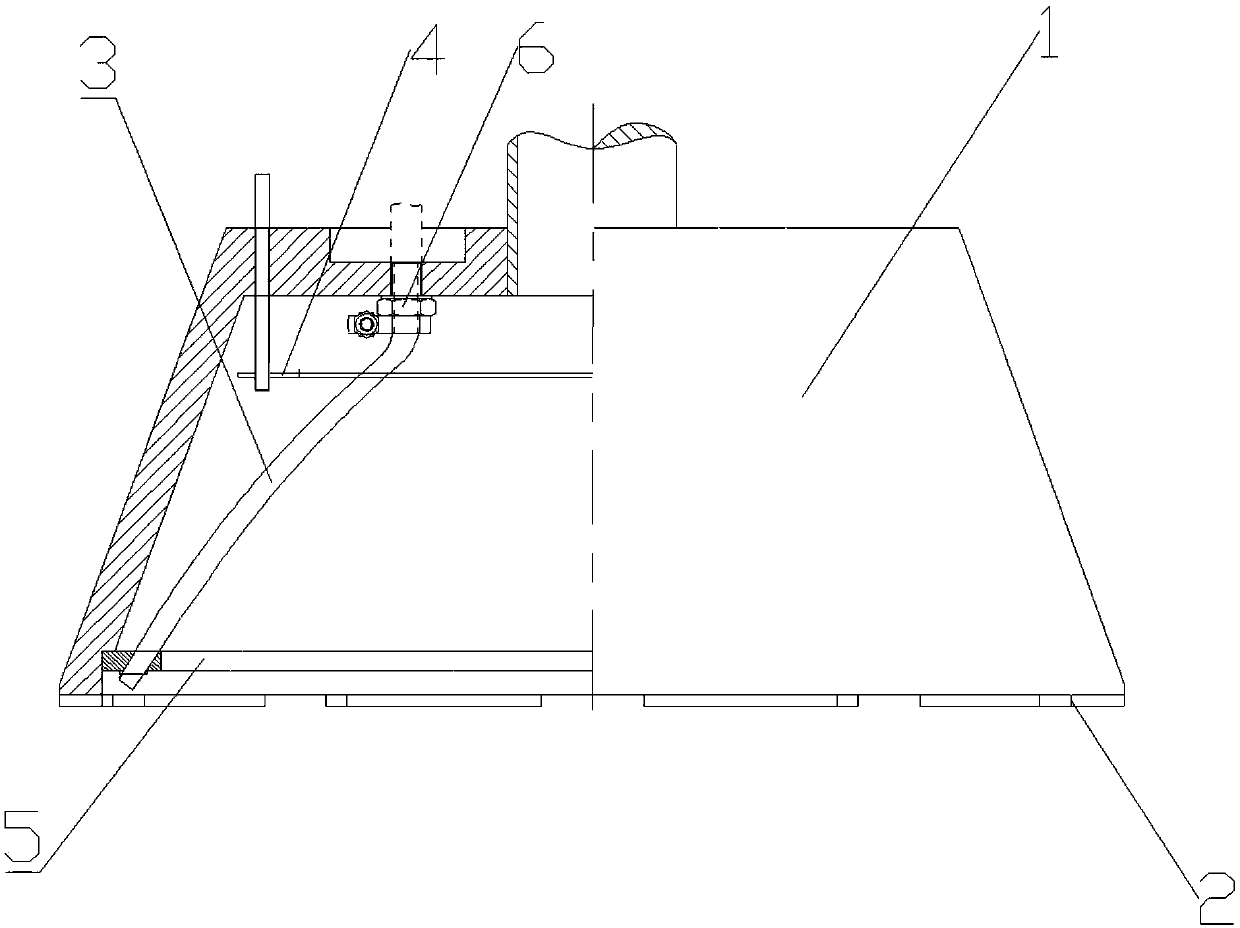

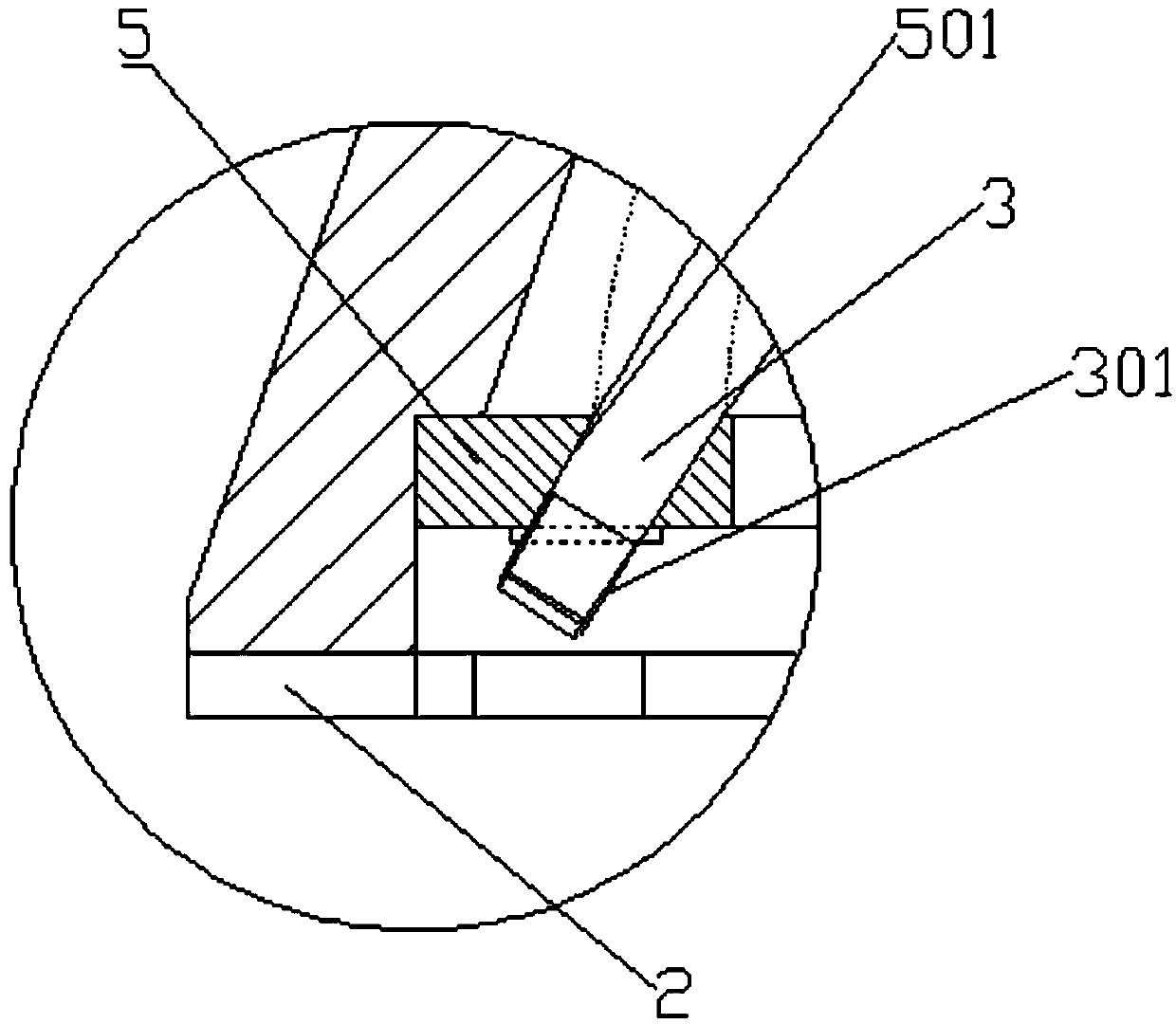

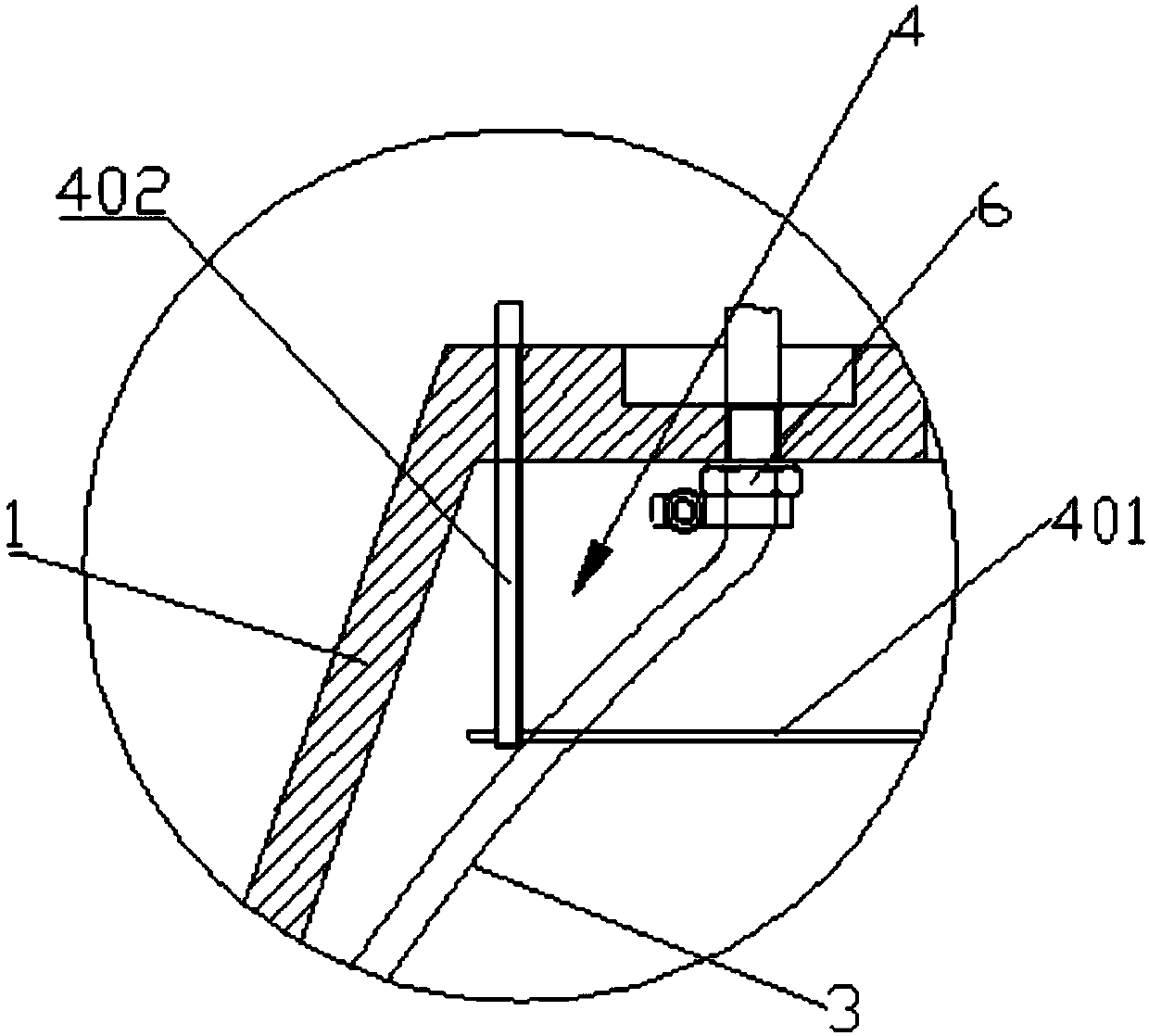

Novel internal cooling grinding abrasive wheel

ActiveCN109551363AIncrease flow rateVelocityGrinding machine componentsBonded abrasive wheelsEngineeringGrinding wheel

A novel internal cooling grinding abrasive wheel comprises an abrasive wheel body and a grinding portion. The abrasive wheel body is provided with a downward opening. The upper end of the abrasive wheel body is connected with a machine tool cutter handle. The grinding portion is arranged at the bottom of the abrasive wheel body. The novel internal cooling grinding abrasive wheel further comprisesa cooling liquid guiding pipe. The cooling liquid guiding pipe is arranged in the inner cavity of the abrasive wheel body. The water inlet head end of the cooling liquid guiding pipe penetrates through the top of the inner cavity of the abrasive wheel body and communicates with a cooling liquid supplying portion. The water outlet tail end of the cooling liquid guiding pipe is fixedly arranged on the inner edge of the lower end of the abrasive wheel body. According to the novel internal cooling grinding abrasive wheel, through the arrangement of the independent cooling liquid guiding pipe, cooling liquid is guided in from the top of the abrasive wheel body and guided to the outer edge of the lower end of the abrasive wheel body, and when the grinding portion conducts grinding, the cooling liquid conducts cooling, lubricating and flushing on the grinding area at the same time; the cooling liquid guiding pipe is independently arranged in the inner cavity of the abrasive wheel body, the technical threshold is lowered, and the production technology is simple; and the internal cooling type abrasive wheel is easier to manufacture and low in production cost.

Owner:XIANGTAN UNIV

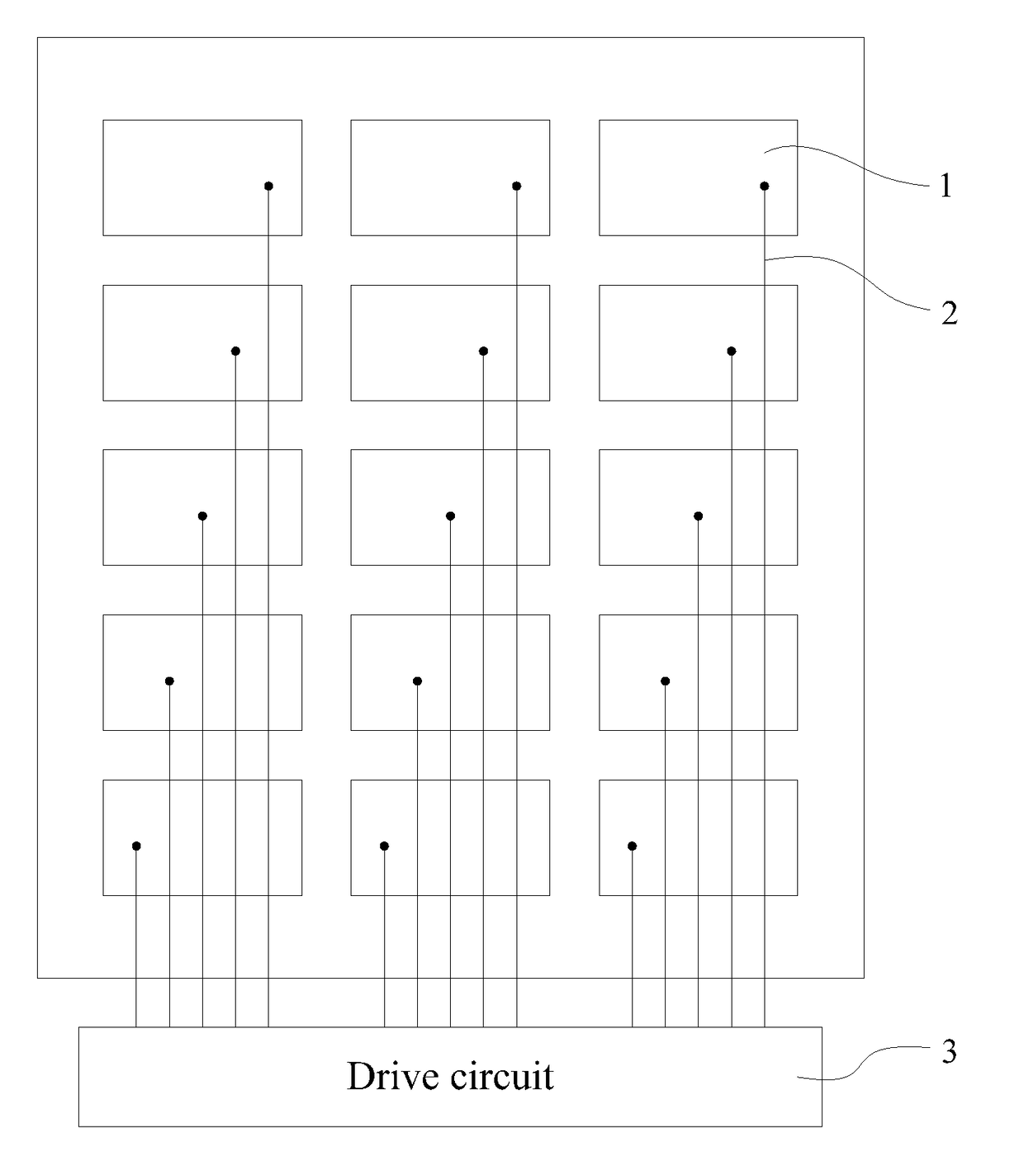

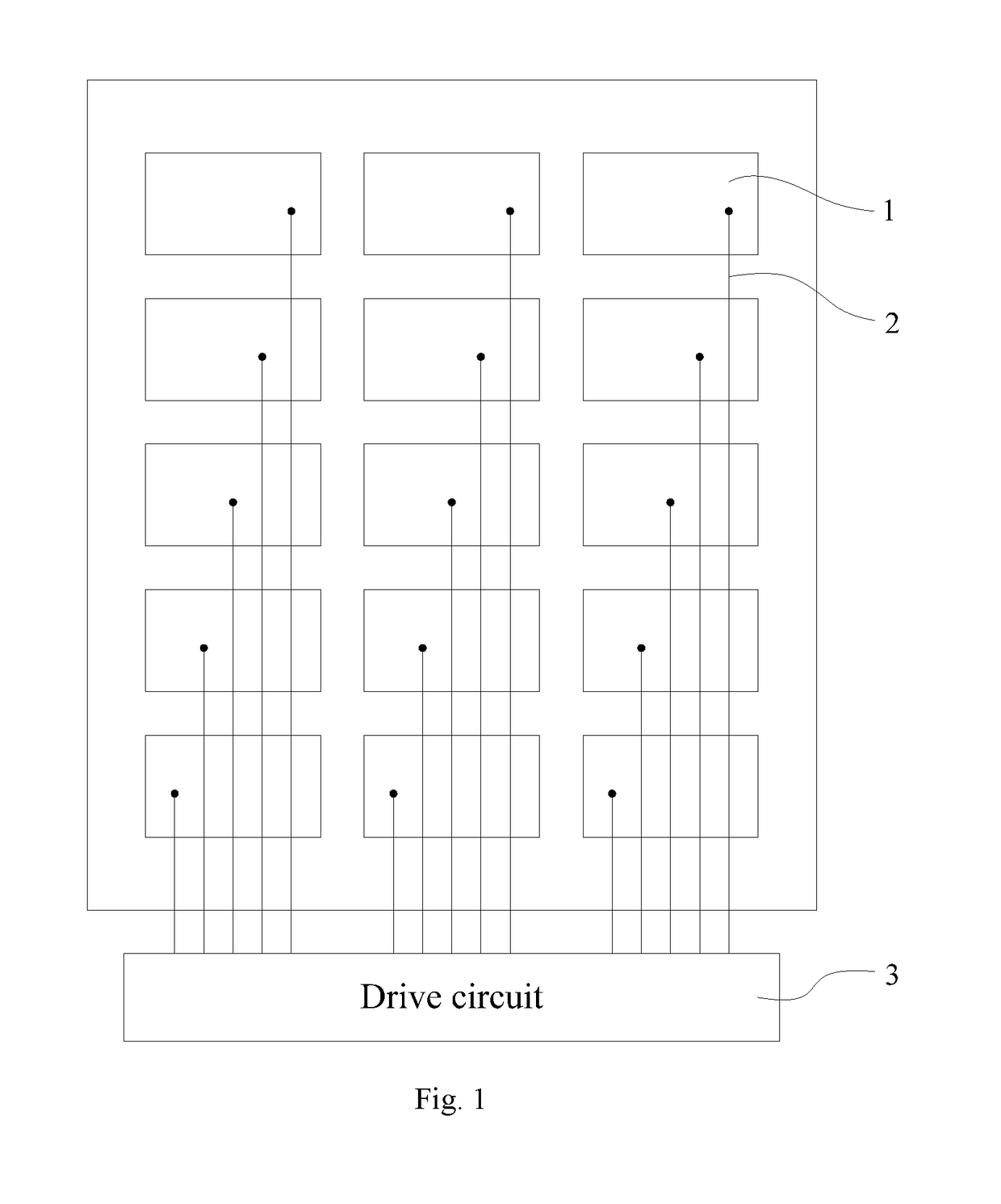

Array substrate and touch display device

ActiveUS20180129090A1Simplify manufacturing processComplex processStatic indicating devicesNon-linear opticsEngineeringScan line

Disclosed is an array substrate and touch display device which belongs to the technical filed of display and is able to solve the technical problem that in the existing technologies, the process of manufacturing an array substrate is too complex. The array substrate includes a drive scan line, a data line, a first common electrode, a second common electrode, a touch scan line, a common transistor, and a touch transistor. The first common electrode and the second common electrode are arranged in a spaced-apart manner. A source and a drain of the common transistor are connected respectively to the first common electrode and the second common electrode, and a gate of the common transistor is connected to the drive scan line. A source and a drain of the touch transistor are connected respectively to the data line and the second common electrode, and a gate of the touch transistor is connected to the touch scan line.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for manufacturing MWT photovoltaic cell with passivated back

InactiveCN103618029AImprove efficiencyComplex processFinal product manufacturePhotovoltaic energy generationElectrical and Electronics engineeringPhotovoltaics

The invention discloses a method for manufacturing an MWT photovoltaic cell with the passivated back. Integrating MWT and back passivation technologies, the manufacturing process is suitable for existing photovoltaic cell production lines. The photovoltaic cell is low in improvement cost and more efficient, and the technology for manufacturing the photovoltaic cell is more complex.

Owner:ALTUSVIA ENERGY TAICANG

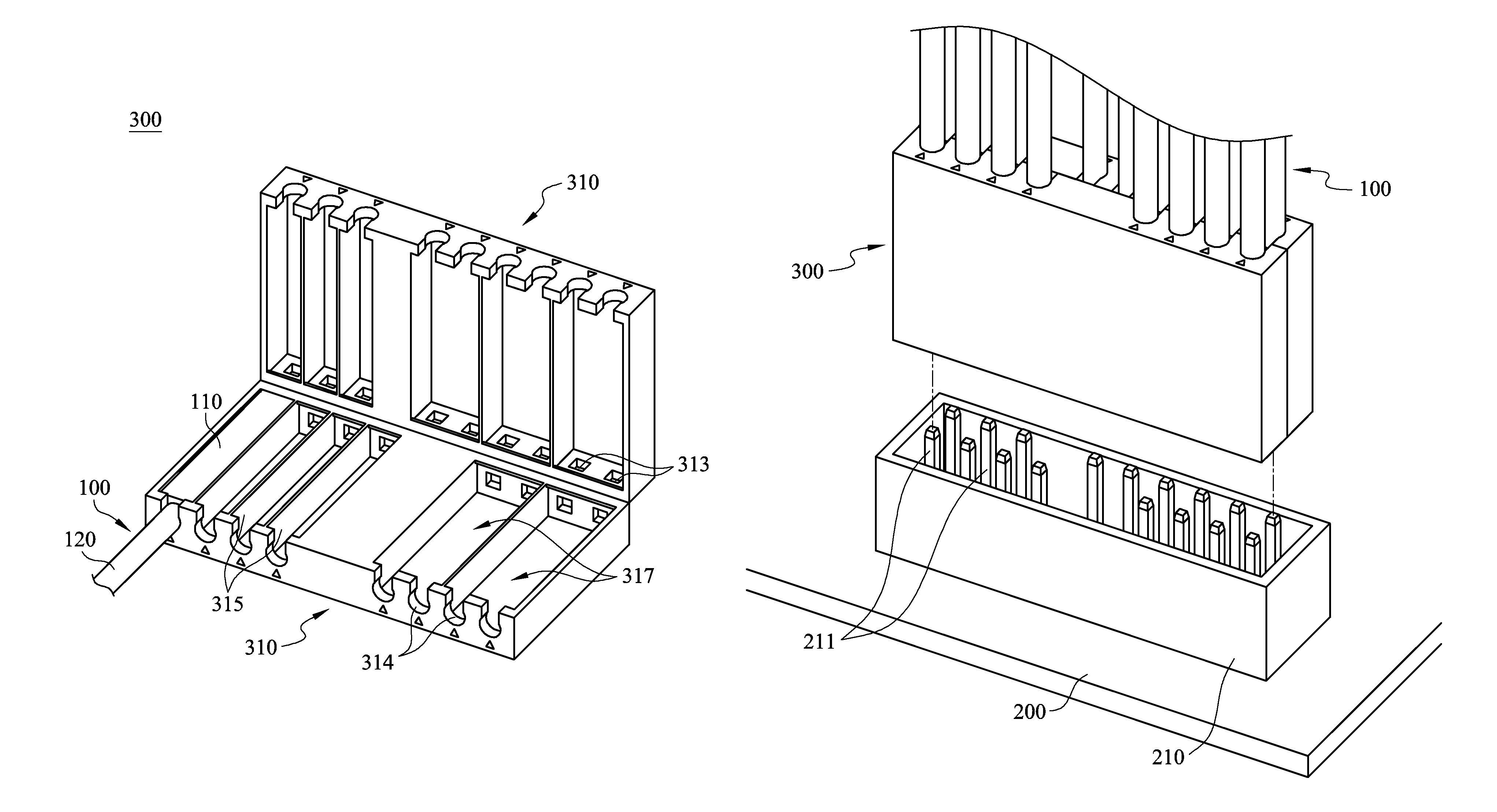

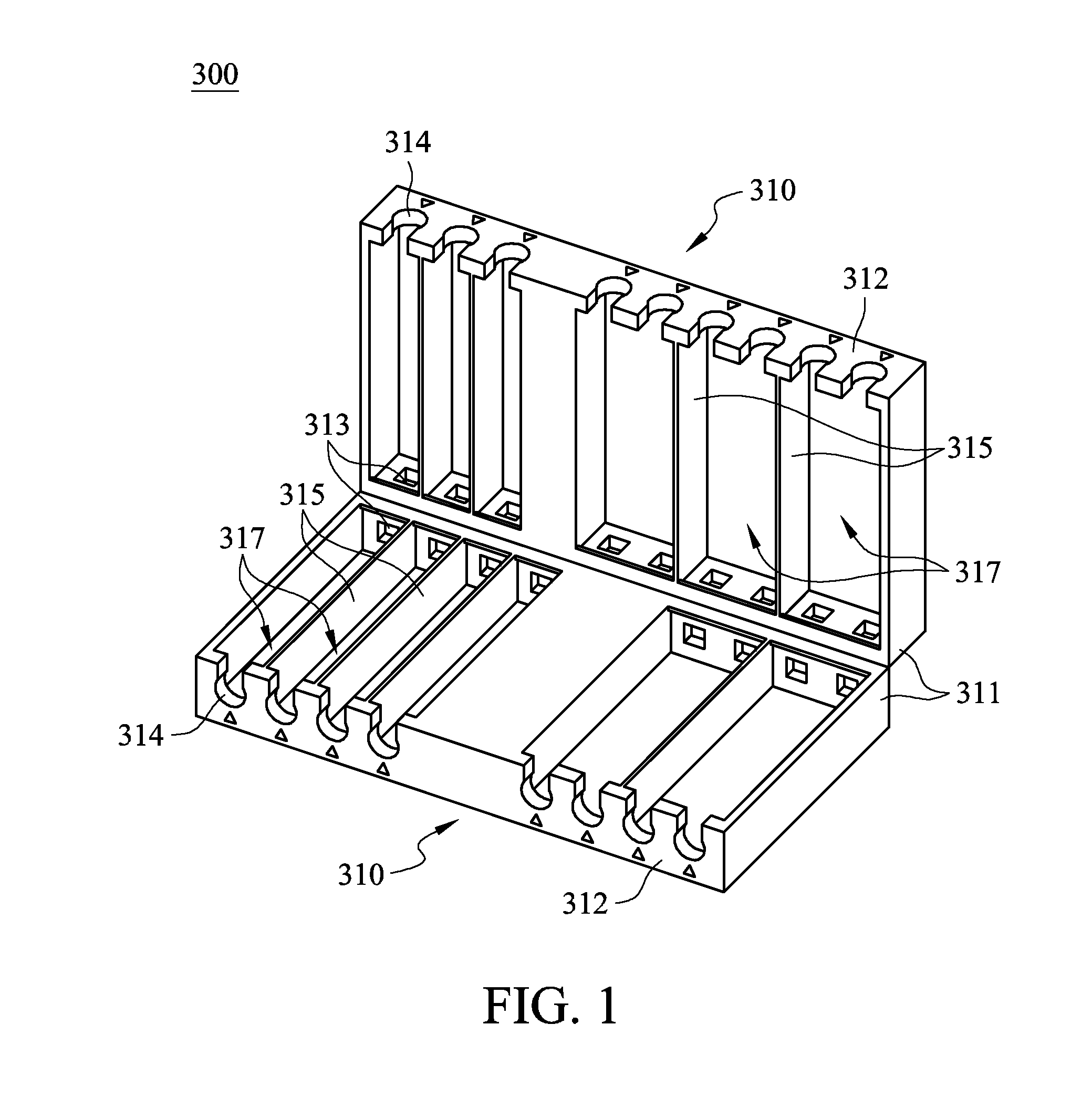

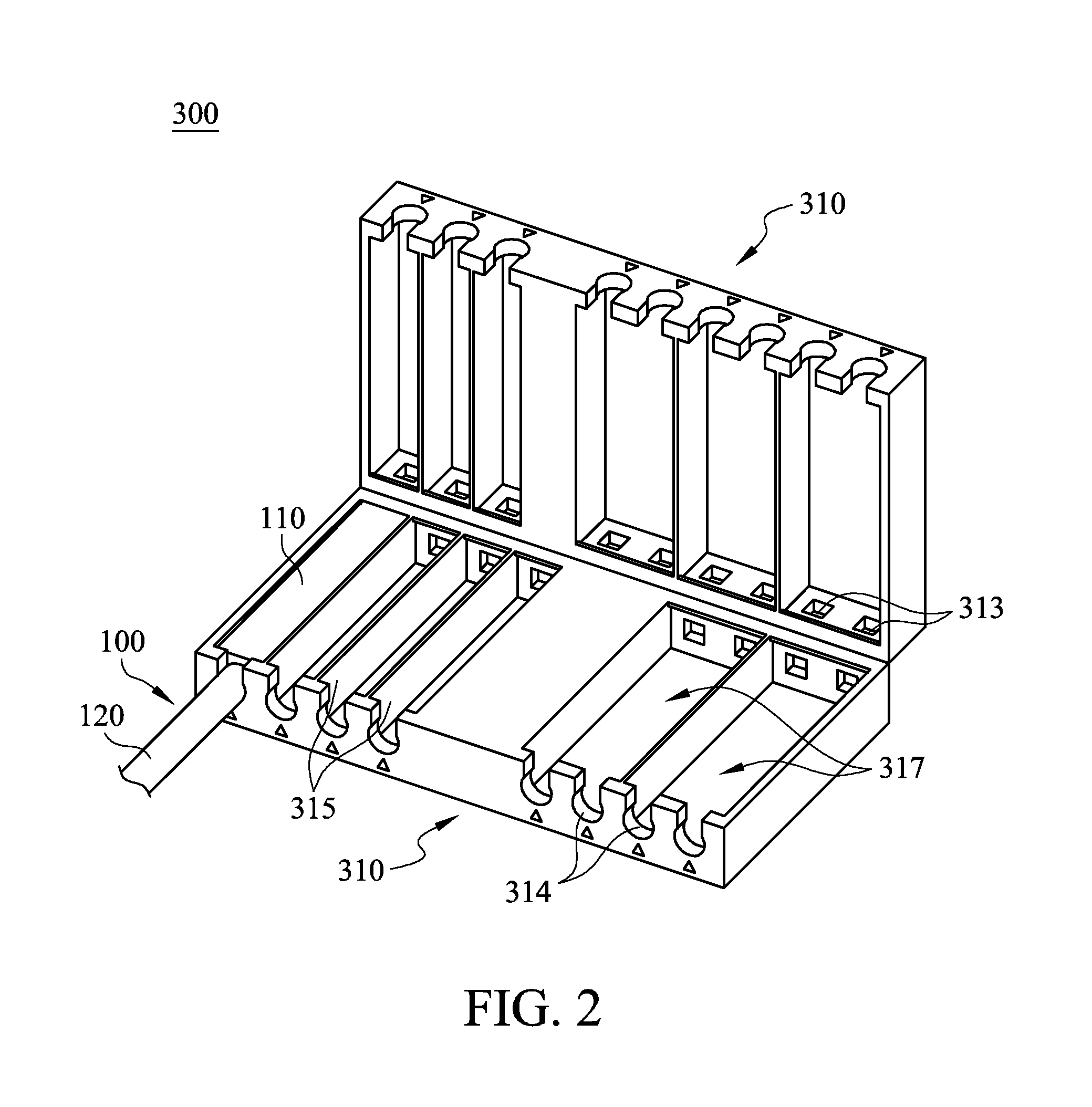

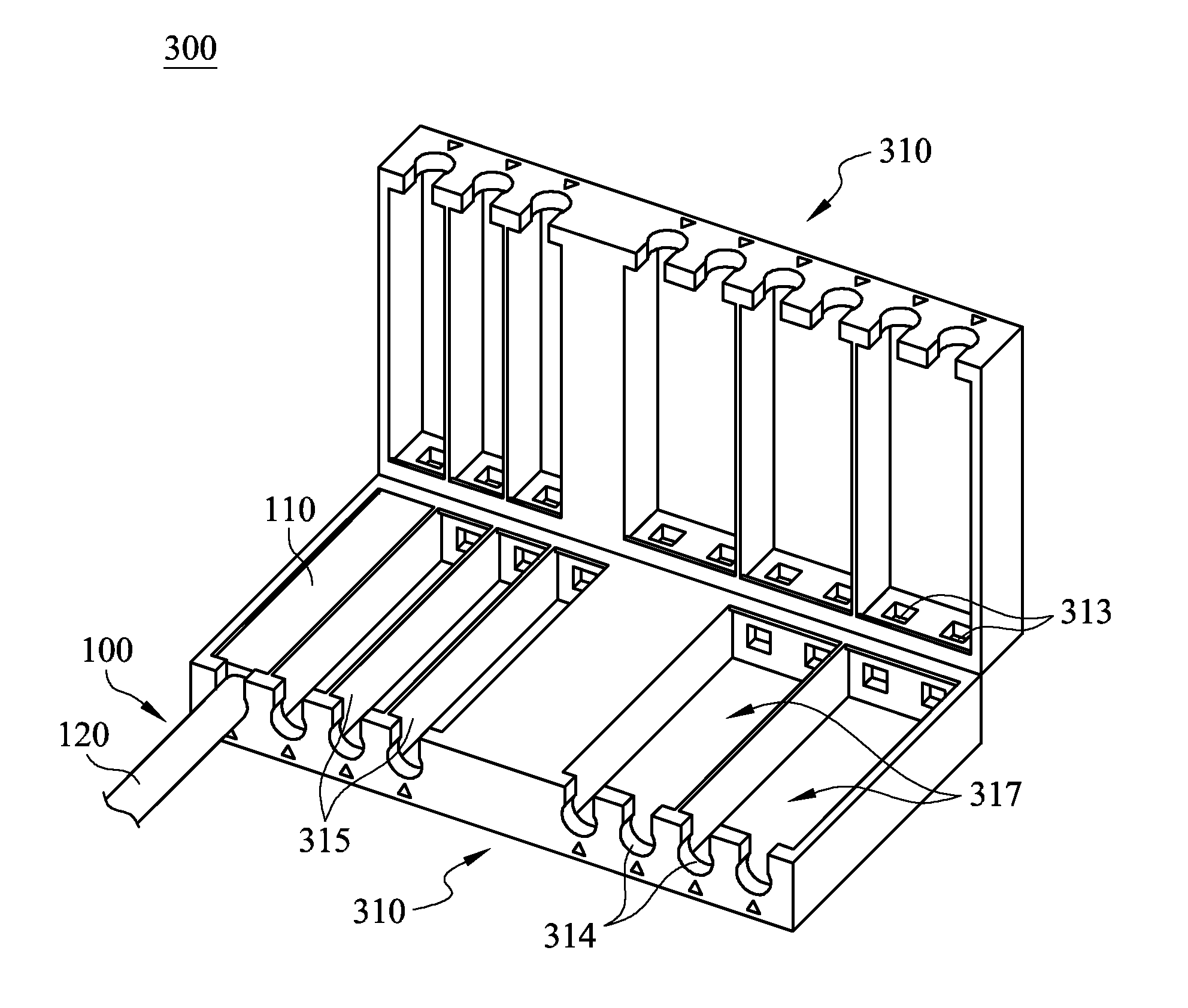

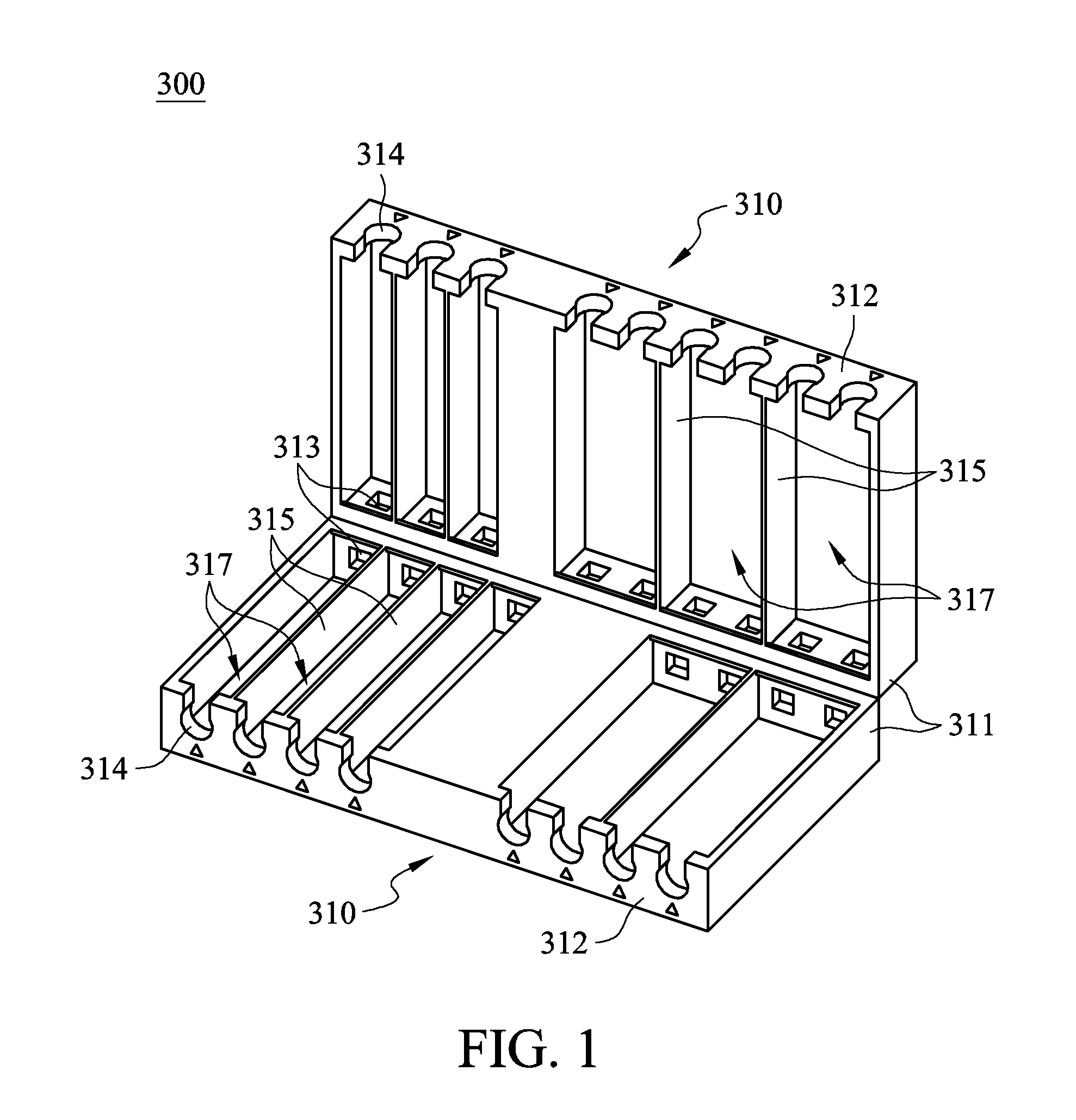

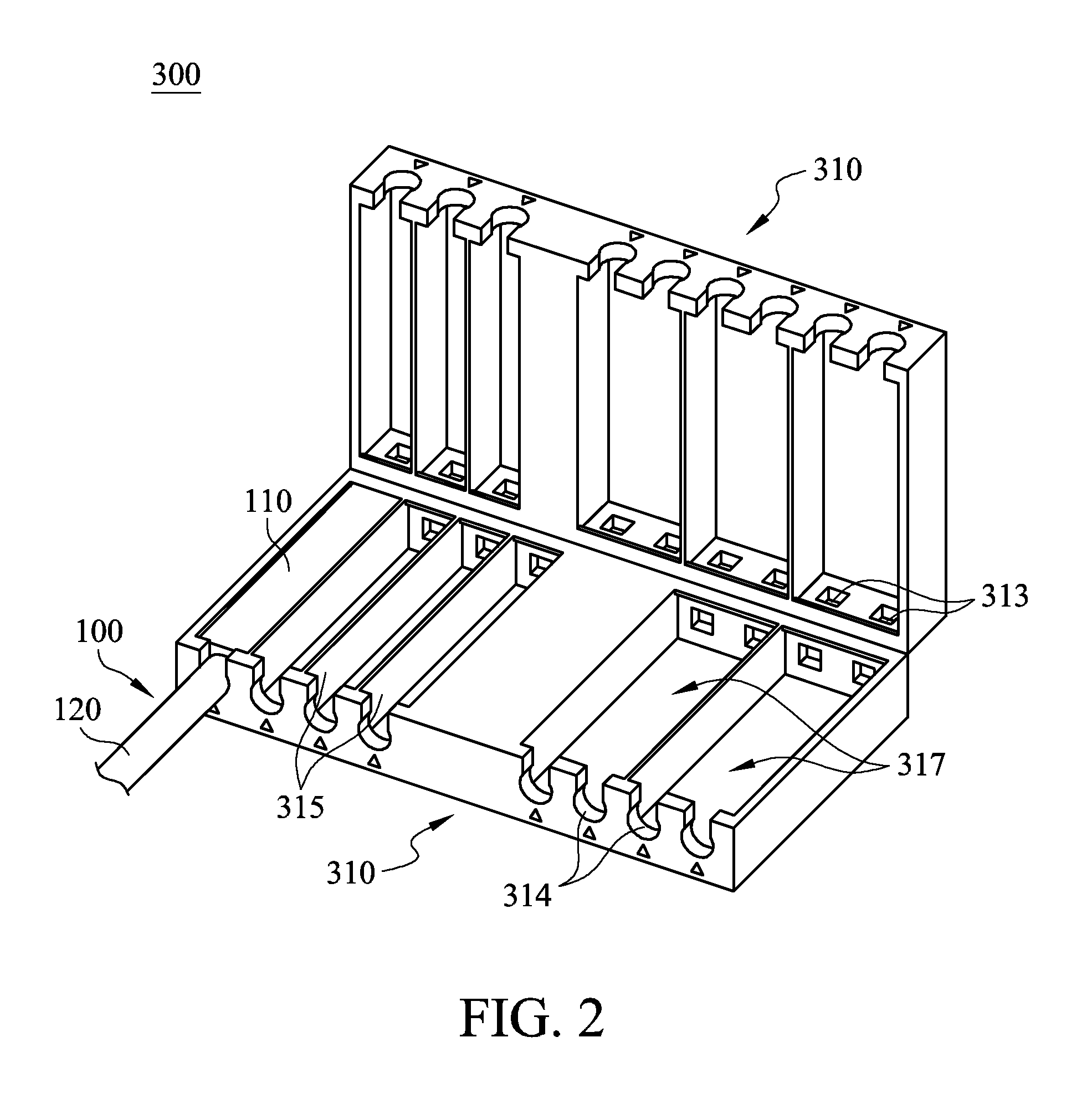

Cable management apparatus

ActiveUS9022805B2Complex processEffective product qualityElectrically conductive connectionsElectric discharge tubesEngineeringCable management

A cable management apparatus includes a half housing and a plurality of partitions. The half housing has a first side surface and a second side surface opposite to each other. The partitions are disposed in the half housing to divide the interior of the half housing into a plurality of compartments, and each compartment extends to the two faces of the half housing. A plurality of signal cables are respectively disposed into the compartments, so that the signal cables are able to be disposed in the electronic slots through the half housing and that the signal cables are electronically connected to the corresponding pins respectively.

Owner:GIGA BYTE TECH CO LTD

Cable management apparatus

ActiveUS20140187083A1Easy and fast assemblyQuick and easy positioningElectrically conductive connectionsCoupling device detailsElectricityCable management

A cable management apparatus includes a housing and a plurality of partitions. The housing has a first side surface and a second side surface opposite to each other. The partitions are disposed in the housing to divide the interior of the housing into a plurality of compartments, and each compartment extends to the two faces of the housing. A plurality of signal cables are respectively disposed into the compartments, so that the signal cables are able to be disposed in the electronic slots through the housing and that the signal cables are electronically connected to the corresponding pins respectively.

Owner:GIGA BYTE TECH CO LTD

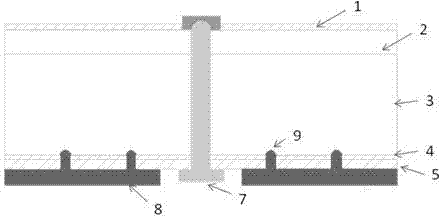

High-reliability image sensor packaging structure without silicon through hole

InactiveCN102339841ASimple structureReduce process difficultyRadiation controlled devicesPhysicsImage sensor

The invention relates to a high-reliability image sensor packaging structure without a silicon through-hole, comprising a chip body (1), wherein an isolated layer (5) is arranged on the upper surface of the chip body, and the isolated layer (5) is provided with a nonopaque cover plate (6); a silicon groove (8) is formed on the chip body; the lower surface of the chip body, a side wall of the silicon groove (8) and the lower surface of an exposed passivation layer (2) in the chip are selectively provided with an insulating layer (9); a blind hole (10) is formed on the exposed passivation layer (2) in the chip; a metal line layer (11) is formed on the surface of the insulating layer (9) and in the blind hole (10) selectively; a line protective layer (12) is arranged on the insulating layer (9) and the metal line layer (11) selectively; and a solder ball (13) is arranged at a position that the metal line layer (11) is exposed out of the line protective layer (12). The structure has the advantages of simple structure, good interconnection reliability, simple technology and low cost.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING

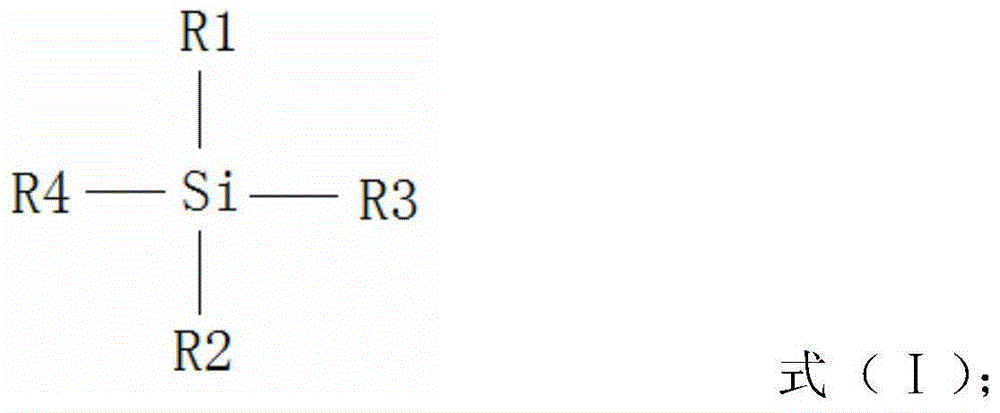

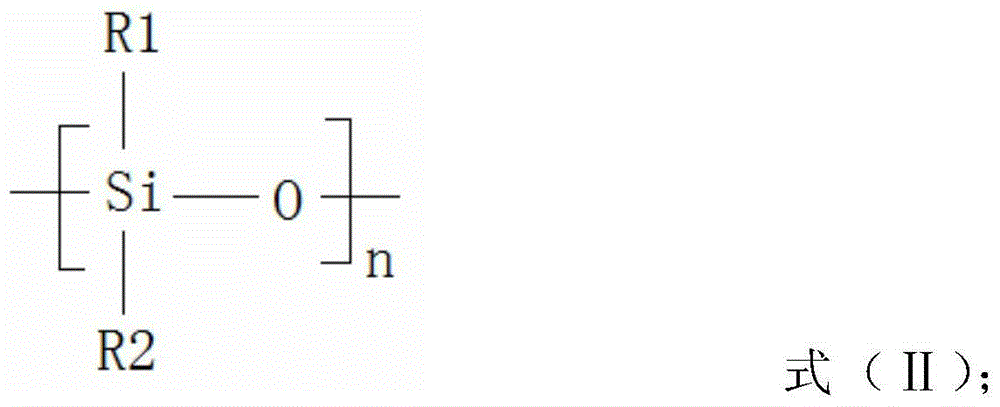

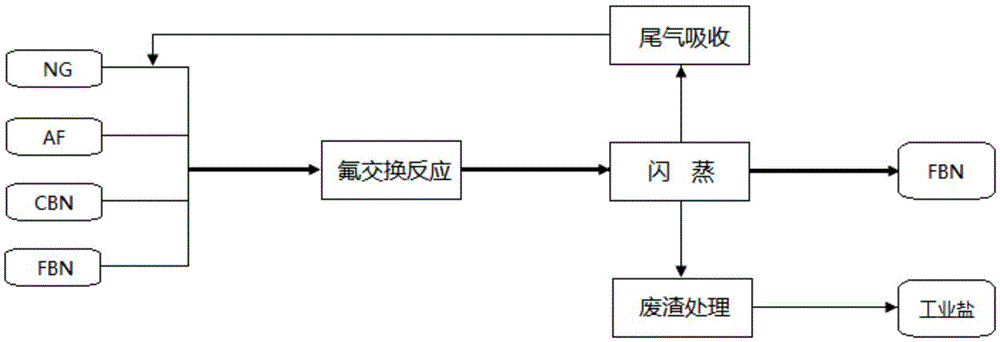

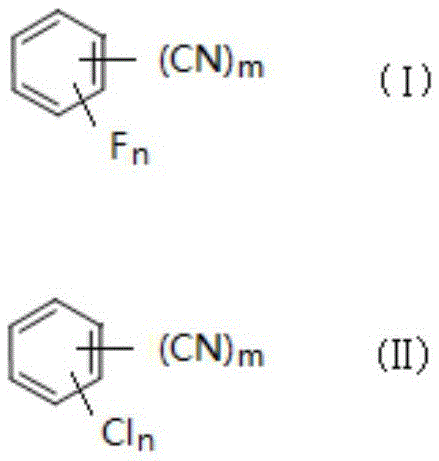

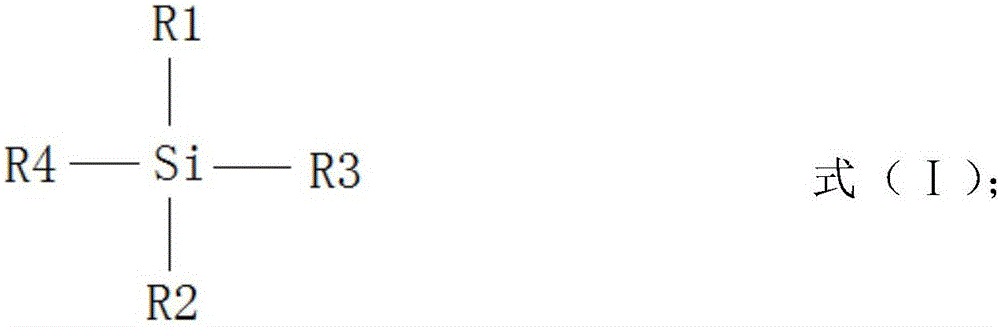

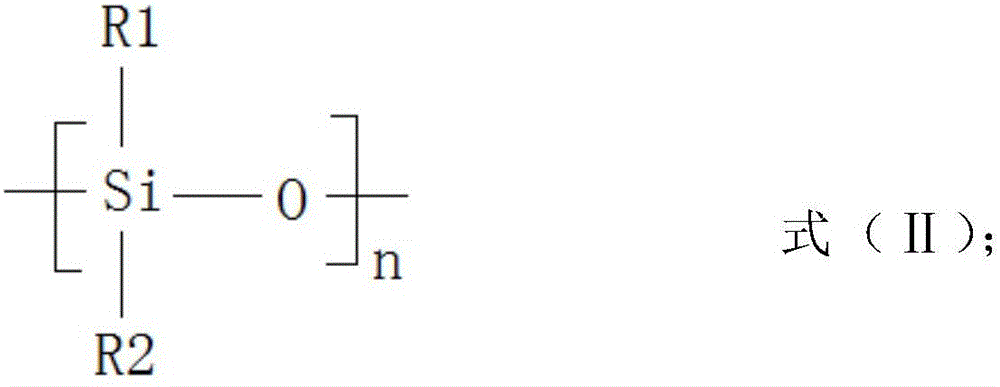

Fluorobenzonitrile compound preparation method

ActiveCN105523962AComplex processHigh energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationHigh pressureSolvent

The present invention provides a fluorobenzonitrile compound preparation method, fluorobenzonitrile compounds are as shown in the general formula (I), an objective product can be prepared from a general-formula-(II)-shown chlorobenzonitrile compound as a raw material by reacting with an anhydrous fluoride in the presence of an inert gas under high temperature high pressure reaction conditions and flashing a reaction product, wherein the objective product itself is used as a solvent. Due to use of the objective product itself as the solvent, a main component of the fluorine exchange reaction product only comprises the objective product, due to use of an inert gas pressurization method to improve the fluorine exchange reaction and product separation conditions, the product is separated and purified in the flashing manner, the reaction residual heat is rationally used, and the whole process is simple and feasible. The method is readily available in raw materials, simple in process, energy-saving, consumption-reducing, and more suitable for industrial scale production.

Owner:DALIAN QIKAI MEDICAL TECH

Display device and electronic device

ActiveUS10504420B2Improve alignment accuracyComplex processTransistorStatic indicating devicesDriver circuitLithography process

The number of lithography processes is reduced and a high-definition display device is provided. The display device includes a pixel portion and a driver circuit for driving the pixel portion. The pixel portion includes a first transistor and a pixel electrode electrically connected to the first transistor. The driver circuit includes a second transistor and a connection portion. The second transistor includes a metal oxide film, first and second gate electrodes that face each other with the metal oxide film positioned therebetween, source and drain electrodes over and in contact with the metal oxide film, and a first wiring connecting the first and second gate electrodes. The connection portion includes a second wiring on the same surface as the first gate electrode, a third wiring on the same surface as the source electrode and the drain electrode, and a fourth wiring connecting the second wiring and the third wiring. The pixel electrode, the first wiring, and the fourth wiring are formed using the same layer.

Owner:SEMICON ENERGY LAB CO LTD

A coupled adsorbent for extracting l-lactic acid from lactic acid acid hydrolysis

ActiveCN104549165BSpecific adsorptionAchieve purificationOther chemical processesCarboxylic compound separation/purificationSorbentCoupling

The invention discloses a coupling adsorbent for extracting an L-lactic acid from a lactic acid acidolysis solution. The coupling adsorbent is prepared from a coupling agent, a load solvent and a coupling promoter at the mass ratio of (20-35) to 100 to (5-15). According to the coupling adsorbent, the L-lactic acid can be extracted from a lactic acid acidolysis solution; an existing process route for gradually separating various kinds of impurities from the L-lactic acid is changed; the L-lactic acid is directly adsorbed by the coupling adsorbent; and various kinds of impurities are left in the residual solution. The coupling adsorbent disclosed by the invention has specific adsorbability on the L-lactic acid; the target of purifying the L-lactic acid in one step is achieved; and a decoloring technology and most of hybridization technologies in an existing technology are removed.

Owner:河南金丹乳酸科技股份有限公司 +1

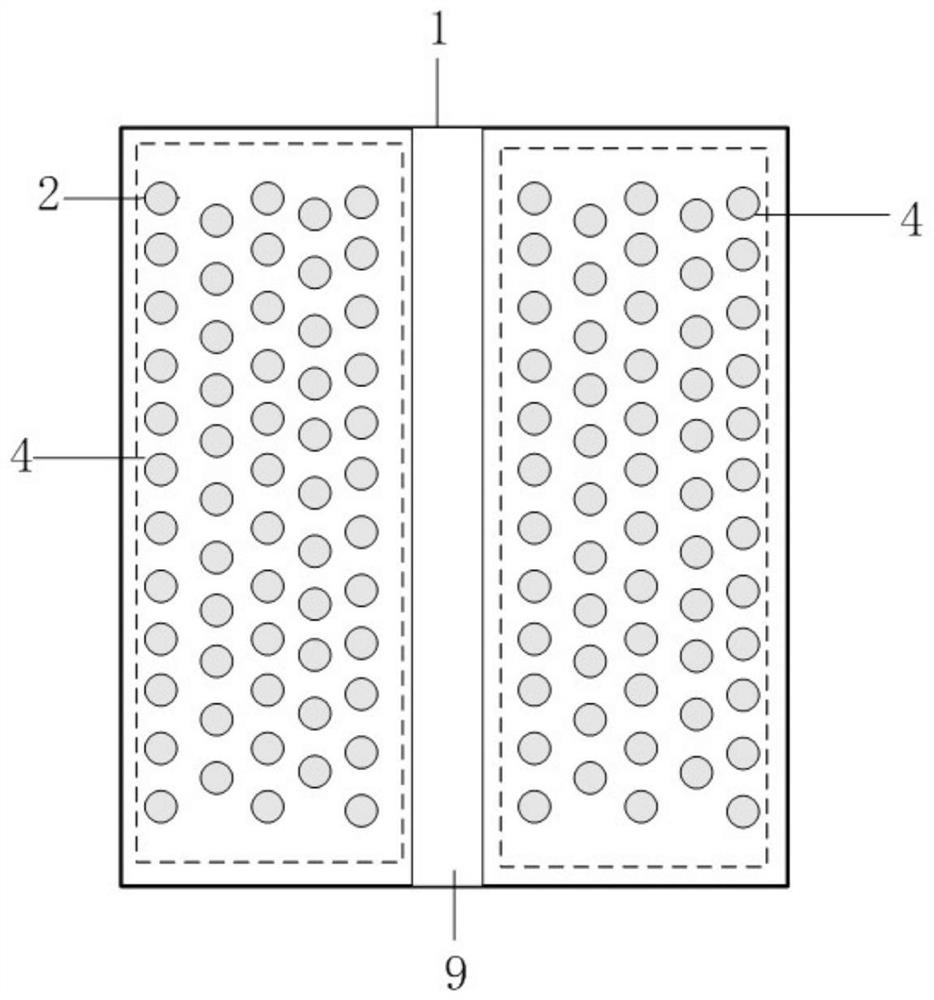

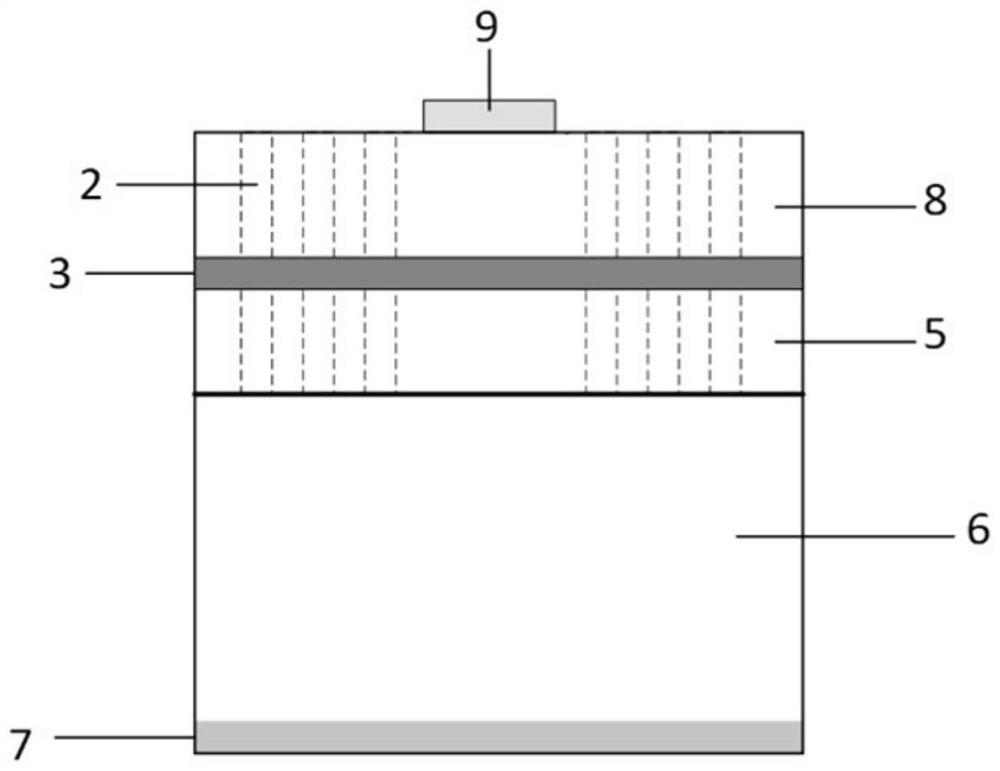

Distributed feedback laser based on air hole and preparation method

PendingCN111916997AHighlight GainReduce volumeLaser optical resonator constructionFinal product manufactureBand gapSlow light

The embodiment of the invention provides a distributed feedback laser based on an air hole and a preparation method. The laser comprises a P electrode, a P doped layer, an active layer, an N doped layer and an N electrode, the two sides of the P electrode are each provided with an air hole waveguide array, each air hole waveguide array is formed by a plurality of air holes, and each air hole penetrates through the P doped layer, the active layer and the N doped layer and is cut off on the upper surface of a substrate. By designing an air hole structure, a two-dimensional planar photonic crystal is formed, a photonic band gap is generated, defects are introduced into the complete photonic crystal, light is limited in the defects by utilizing the photonic band gap to form a line defect photonic crystal waveguide, and the light gain of a unit transmission distance can be increased by a slow light effect generated in the photonic band gap in a defect mode; and the laser lasing condition that the gain exceeds the loss is easy to realize, so the resonant cavity structure of a traditional DFB-LD laser can be shortened, the size of a chip is reduced, and the integratable performance of thechip is improved.

Owner:TSINGHUA UNIV

Workpiece processing system

InactiveCN1943007AReduce pollutionShorten the timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingHEAD SPINNINGEngineering

A system for processing a workpiece includes a process head assembly and a base assembly. The process head assembly has a process head and an upper rotor. The base assembly has a base and a lower rotor. The base and lower rotor have magnets wherein the upper rotor is engageable with the lower rotor via a magnetic force created by the magnets. The engaged upper and lower rotors form a process chamber where a semiconductor wafer is positioned for processing. Process fluids for treating the workpiece are introduced into the process chamber, optionally while the processing head spins the workpiece. Additionally, air flow around and through the process chamber is managed to reduce particle adders on the workpiece.

Owner:APPLIED MATERIALS INC

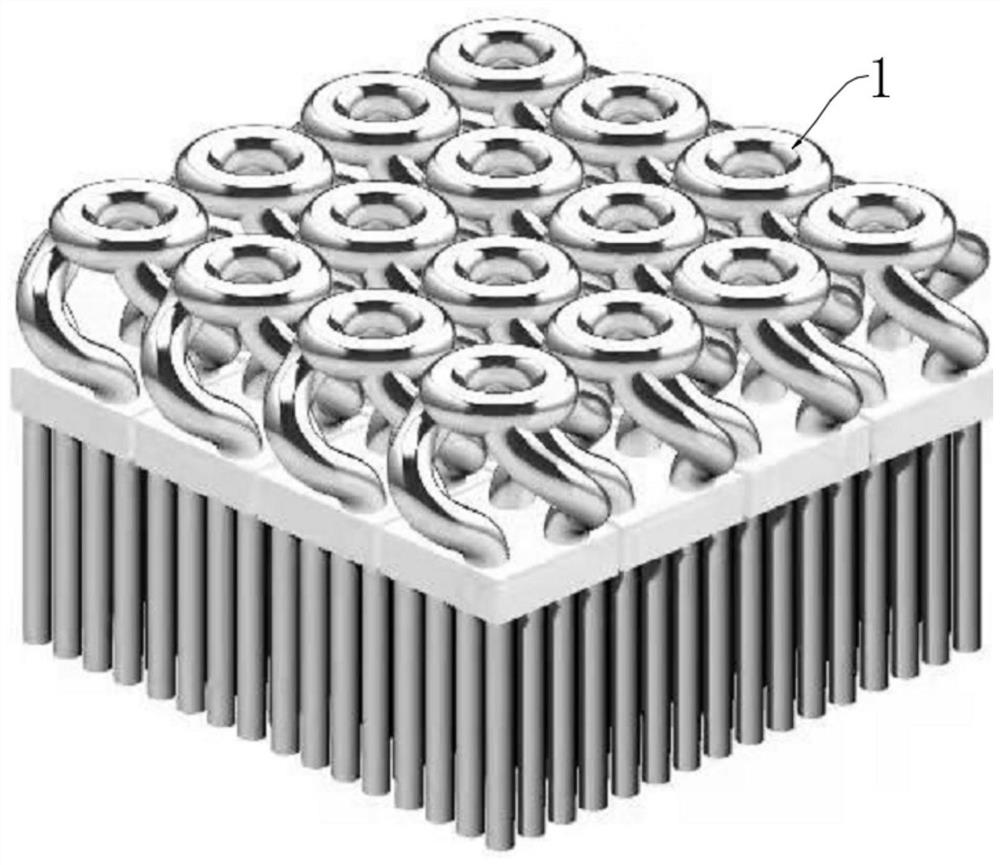

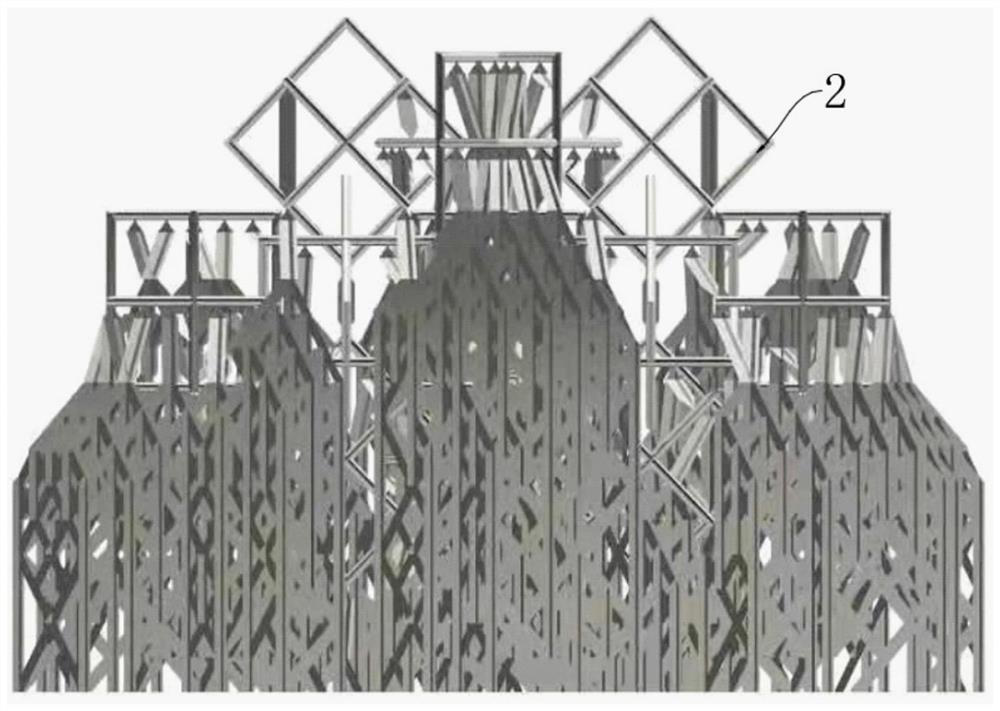

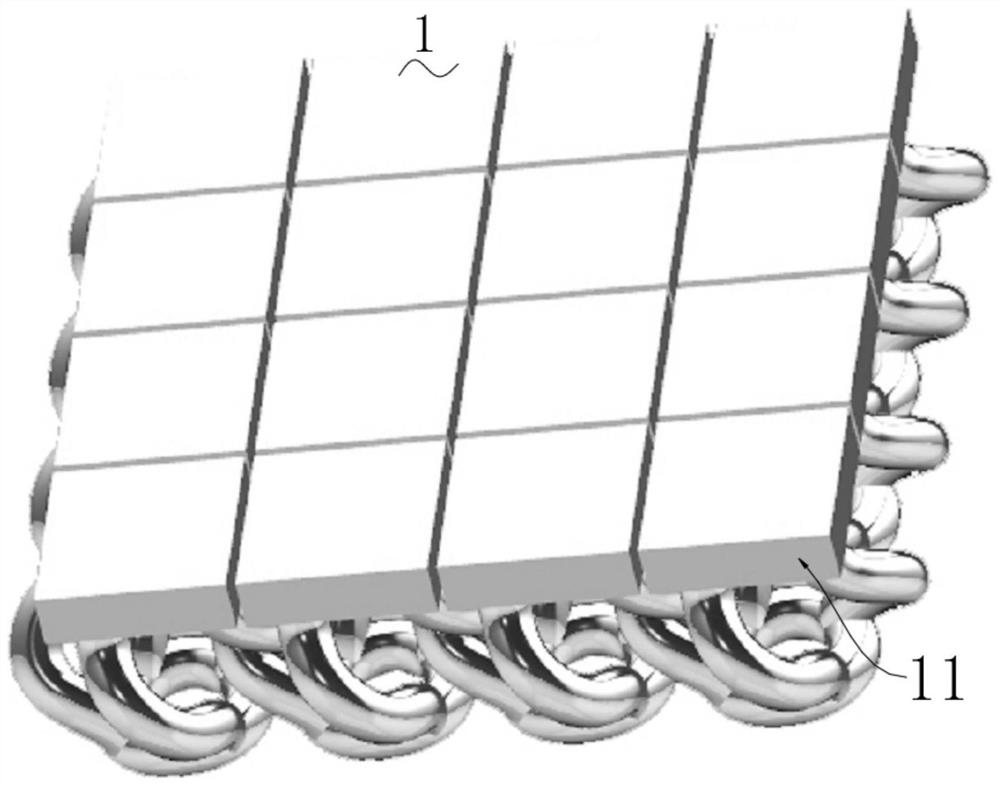

Wearable jewelry based on SLM three-dimensional printing technology and preparation method thereof

ActiveCN114054771AChange shape arbitrarilyExquisite appearanceAdditive manufacturing apparatusIncreasing energy efficiencyEngineering3 dimensional printing

The invention provides a wearable jewelry based on an SLM three-dimensional printing technology, the wearable jewelry comprises a flexible movable structure and / or lightweight crystal lattices, one side of the flexible movable structure is provided with a reflecting surface, and the flexible movable structure is formed by interlocking and connecting first unit crystal lattices; the lightweight crystal lattices are formed by interlocking and connecting second unit lattices, every two adjacent second unit lattices mutually rotate by 45 degrees, and all the second unit lattices are interlocked in topology without forming solid connection. The invention further provides a preparation method of the wearable jewelry based on the SLM three-dimensional printing technology, the jewelry is manufactured by adopting the fabric with the lightweight crystal lattices and the flexible movable structure as the base material, the jewelry can be freely bent, folded and bent in a covering mode, the degree of freedom is good, and the appearance of the fabric can be freely changed according to the design of the jewelry, therefore, the manufactured jewelry is more exquisite in appearance and more complex in process, and has extremely high ornamental value and artistic value.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com