A coupled adsorbent for extracting l-lactic acid from lactic acid acid hydrolysis

An acid hydrolyzate and adsorbent technology, applied in the field of L-lactic acid extraction, can solve the problems of long process flow, large discharge of waste water and waste residue, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the coupling adsorbent for extracting L-lactic acid from lactic acid acid hydrolysis solution consists of 20 kg of coupling agent, 100 kg of loading solvent and 5 kg of coupling accelerator. The coupling agent is dimethylsiloxane, the loading solvent is kerosene, and the coupling accelerator is soybean lecithin.

[0024] At 24 degrees Celsius, the coupling adsorbent of this embodiment and the lactic acid acid hydrolysis solution with a mass fraction of L-lactic acid of 25% were added to the centrifugal extractor respectively, and the mass ratio of the coupling adsorbent to the lactic acid acid hydrolysis solution was 1: 3. The aqueous phase and the organic phase are separated, and the mass percentage content of L-lactic acid in the aqueous phase is detected. The results showed that 80.2wt% of L-lactic acid in the lactic acid acid hydrolysis solution was extracted by the coupled adsorbent.

Embodiment 2

[0026] In this embodiment, the coupling adsorbent for extracting L-lactic acid from lactic acid acid hydrolyzate consists of 25 kg of coupling agent, 100 kg of loading solvent and 8 kg of coupling accelerator. The coupling agent is polydimethylsiloxane, the loading solvent is oleyl alcohol, and the coupling accelerator is soybean lecithin.

[0027] At 24 degrees Celsius, the coupling adsorbent of this embodiment and the lactic acid acid hydrolysis solution with a mass fraction of L-lactic acid of 25% were added to the centrifugal extractor respectively, and the mass ratio of the coupling adsorbent to the lactic acid acid hydrolysis solution was 1: 3. The aqueous phase and the organic phase are separated, and the mass percentage content of L-lactic acid in the aqueous phase is detected. The results showed that 82.1wt% of L-lactic acid in the lactic acid acid hydrolysis solution was extracted by the coupled adsorbent.

Embodiment 3

[0029] In this embodiment, the coupling adsorbent for extracting L-lactic acid from lactic acid acid hydrolyzate consists of 35 kg of coupling agent, 100 kg of loading solvent and 15 kg of coupling accelerator. The coupling agent is dimethylsiloxane with hydroxyl groups.

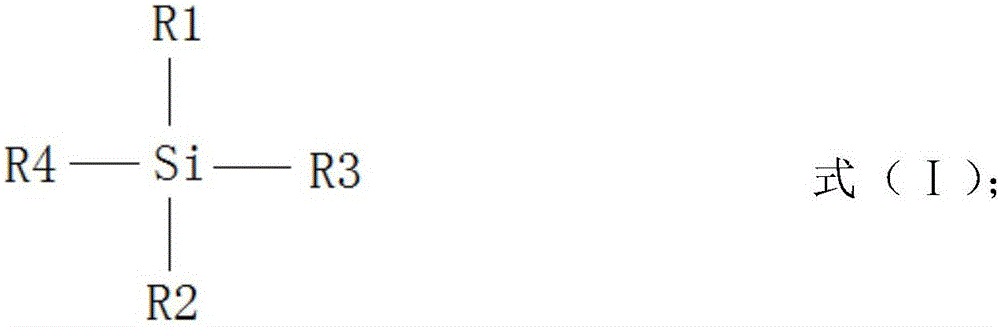

[0030] The dimethylsiloxane with hydroxyl is shown in formula (I):

[0031] Formula (I);

[0032] In formula (I): R3 and R4 are both CH 3 O-, R1 is CH 3 -, R2 is HOCH 2 CH 2 CH 2 -. The loading solvent is methyl acetate, and the coupling accelerator is soybean lecithin.

[0033] At 24 degrees Celsius, the coupling adsorbent of this embodiment and the lactic acid acid hydrolysis solution with a mass fraction of L-lactic acid of 25% were added to the centrifugal extractor respectively, and the mass ratio of the coupling adsorbent to the lactic acid acid hydrolysis solution was 1: 3. The aqueous phase and the organic phase are separated, and the mass percentage content of L-lactic acid in the aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com