A kind of mofs/mips catalyst and its in-situ growth preparation method and application

An in-situ growth and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of high cost, low efficiency of chemical treatment, and difficult degradation Pollutants and other problems, to achieve the effect of enhanced stability, easy control of reaction conditions, and simple and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this example, the effects of different reaction conditions on the adsorption of DMP by MIPs were compared.

[0048] A preparation method of MIPs, comprising the steps of:

[0049] (1) Add the template molecule (DMP), functional monomer (MAA) and porogen (acetonitrile) into a 50mL centrifuge tube for ultrasonic dispersion, and then carry out pre-polymerization reaction,

[0050] The reaction conditions were controlled to the following 6 types (as shown in Table 1 below).

[0051] Table 1

[0052]

[0053] Six kinds of pre-polymerized reactants were obtained, named as Pre-MIPs-1, Pre-MIPs-2, Pre-MIPs-3, Pre-MIPs-4, Pre-MIPs-5 and Pre-MIPs-6;

[0054] (2) Preparation of hemispherical MIPs by bulk polymerization: the reaction of the crosslinking agent ethylene glycol dimethacrylate (EGDMA), the initiator azobisisobutyronitrile (AIBN) and the prepolymerization described in step (1) The product (Pre-MIPs-3 is selected here) is mixed evenly, and then heated in a water...

Embodiment 2

[0068] This example compares the effects of different reaction conditions on the targeted degradation of DMP by MOFs / MIPs.

[0069] A kind of in-situ growth preparation method of MOFs / MIPs catalyst, comprises the following steps:

[0070] (1) Preparation of MOFs / MIPs and MOFs / NIPs by in situ growth method: DMF (dimethylformamide), 2,5-dihydroxyterephthalic acid, ferrous chloride, water, methanol (analytically pure, 99.5 %) and the imprinted polymer (here MIPs-3) prepared in step (4) of Example 1 were uniformly mixed in a reaction kettle to obtain a mixed solution, which was uniformly dispersed by ultrasonic and heated in an oven.

[0071] Reaction condition is controlled as following 6 kinds (as shown in table 4 below);

[0072] Table 4

[0073]

[0074]

[0075] The products obtained above (heating product-1, heating product-2, heating product-3, heating product-4, heating product-5 and heating product-6) were washed with DMF respectively, and then soaked in methanol ...

Embodiment 3

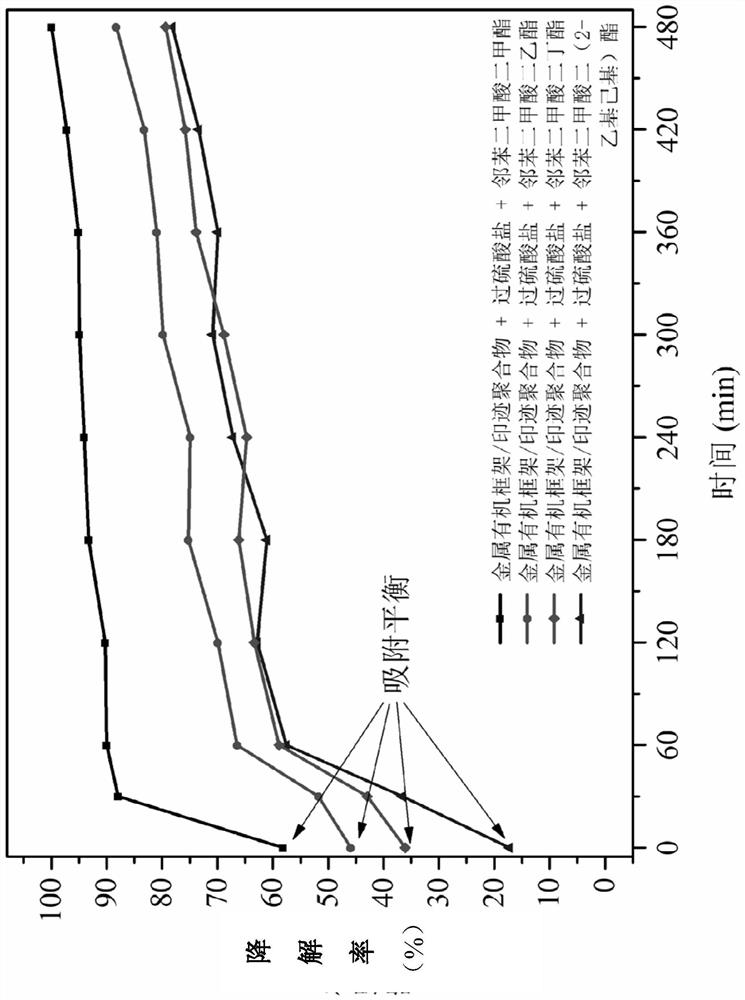

[0085] This example compares the targeting selectivity of MOFs / MIPs catalysts to DMP.

[0086] Three structural analogues of DMP were selected, namely diethyl phthalate (DEP) solution, dibutyl phthalate (DBP) solution and bis(2-ethyl phthalate) Di-2-ethylhexyl phthalate (DEHP)) was used to study the target selectivity of MOFs / MIPs catalysts for DMP. Prepare DMP solution, DEP solution, DBP solution and DEHP solution that initial concentration is 30mg / L respectively, add the MOFs / MIPs catalyst (MOFs / MIPs-2) that embodiment 2 makes respectively to above-mentioned four kinds of solutions, embodiment 2 The prepared MOFs / MIPs catalyst was added in an amount of 2.4g / L (that is, 2.4g of catalyst was added per liter of solution), and the adsorption reaction was carried out in a shaker at 180rpm at room temperature (25°C) for 24h (to ensure that the adsorption Equilibrium), add oxidant PS (persulfate (Persulfate, PS)) to 4 kinds of solutions respectively, the molar ratio of the additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com