Preparation method of biomass charcoal material for removing phosphorus from sewage

A technology of biochar and sewage, which is applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of general adsorption performance, insufficient surface functional groups, and non-specificity of adsorbate adsorption. Achieve good adsorption capacity and good phosphorus adsorption specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

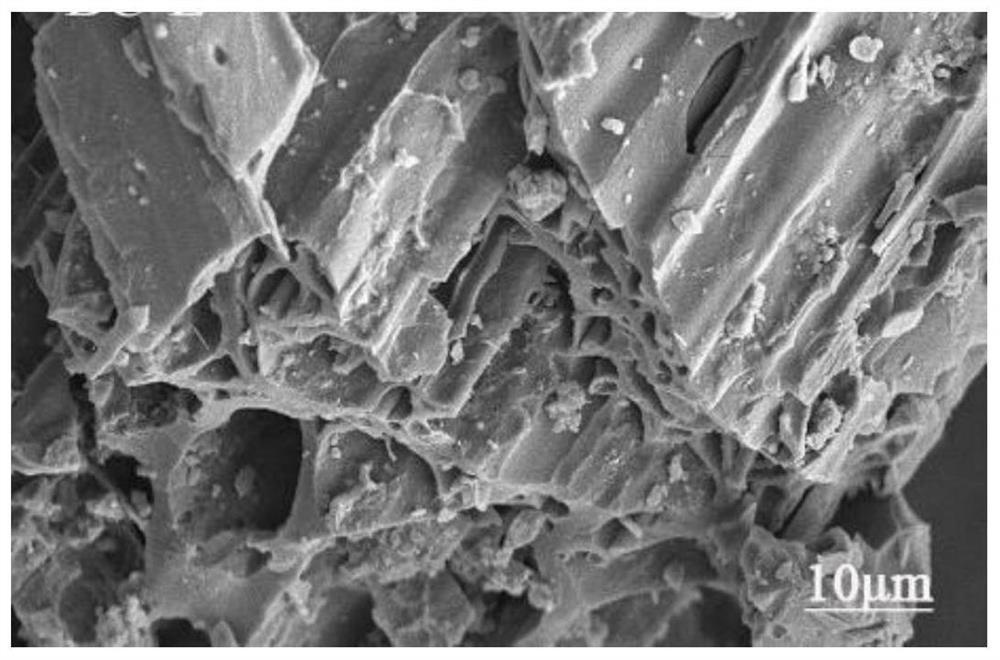

Image

Examples

Embodiment 1

[0016] A method for preparing a biochar material for phosphorus removal from sewage, specifically comprising the following steps:

[0017] S1: Collect reed straw, the raw material of biochar, and dry it in the sun, then soak it in an aqueous sodium hydroxide solution with a molar concentration of 5 mol / L for 6 hours, filter, wash with distilled water until neutral, and heat and dry at 80°C , crushed into particles with a particle size of 4mm, and set aside.

[0018] S2: Add lanthanum nitrate to distilled water, ultrasonically dissolve, then add the particles in step S1 to the solution, stir for 3 hours, move it to a high-pressure reactor, react at 120°C for 2 hours, cool, filter, placed in a tube furnace, and calcined at 600° C. for 2 h in an atmosphere of a nitrogen-hydrogen gas mixture with a content ratio of 90%:10%, to obtain a biochar precursor.

[0019] S3: Add the biochar precursor to distilled water, then add dopamine, add Tris-HCl buffer solution during stirring, sti...

Embodiment 2

[0021] A method for preparing a biochar material for phosphorus removal from sewage, specifically comprising the following steps:

[0022] S1: Collect rice straw as a raw material for biochar and dry it in the sun, then soak it in an aqueous sodium hydroxide solution with a molar concentration of 8 mol / L for 8 hours, filter, wash with distilled water until neutral, and heat and dry at 95°C , crushed into particles with a particle size of 6mm, and set aside.

[0023] S2: Add lanthanum chloride to distilled water, ultrasonically dissolve, then add the particles in step S1 to the solution, stir for 6 hours, move it to a high-pressure reactor, react at 130°C for 3 hours, cool, and filter , placed in a tube furnace, and calcined at 750° C. for 4 hours in an atmosphere of a nitrogen-hydrogen gas mixture with a content ratio of 90%:10%, to obtain a biochar precursor.

[0024] S3: Add the biochar precursor to distilled water, then add dopamine, add Tris-HCl buffer solution during the...

Embodiment 3

[0026] A method for preparing a biochar material for phosphorus removal from sewage, specifically comprising the following steps:

[0027] S1: Collect kelp as a raw material for biochar and dry it in the sun, then soak it in an aqueous sodium hydroxide solution with a molar concentration of 6 mol / L for 7 hours, filter, wash with distilled water until neutral, and heat and dry at 85°C. Crush into particles with a particle size of 5 mm and set aside.

[0028] S2: Add lanthanum sulfate to distilled water, ultrasonically dissolve, then add the particles in step S1 to the solution, stir for 4 hours, move it to a high-pressure reactor, react at 125°C for 2.5 hours, cool, and filter , placed in a tube furnace, and calcined at 650° C. for 3 h in a mixed gas atmosphere of nitrogen and hydrogen with a content ratio of 90%:10%, to obtain a biochar precursor.

[0029] S3: Add the biochar precursor to distilled water, then add dopamine, add Tris-HCl buffer solution during stirring, stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com