Preparation method of spherical mesoporous carbon with adjustable particle size

A mesoporous carbon and spherical technology, which is applied in the field of preparation of spherical mesoporous carbon, can solve the problems of unclear and immature preparation technology of spherical mesoporous carbon particle size, and achieve the effect of good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of embodiment 1 spherical mesoporous carbon

[0042] This implementation provides a method for preparing spherical mesoporous carbon after parameter optimization.

[0043] 1. Preparation of resole phenolic resin

[0044] Melt 40g of phenol at 38°C, add 60mL of 0.5mol / L sodium hydroxide solution, stir well, add 100mL of 37% formaldehyde solution; heat up to 75°C, continue stirring for 0.6h, reflux and cool the mixture to room temperature , adjust the pH value to 7.0 with 2mol / L hydrochloric acid solution; then distill under reduced pressure at 48°C to remove the water in the mixture to obtain a resole phenolic resin.

[0045] 2. Preparation of resole phenolic resin-chromium nitrate-ethanol solution

[0046] According to C, Cr molar ratio is 33:1, resole phenolic resin and Cr (NO 3 ) 3 9H 2 O was mixed and dissolved in ethanol to form a resole phenolic resin-chromium nitrate-ethanol solution with a mass fraction of 48% resole phenolic resin.

...

Embodiment 2

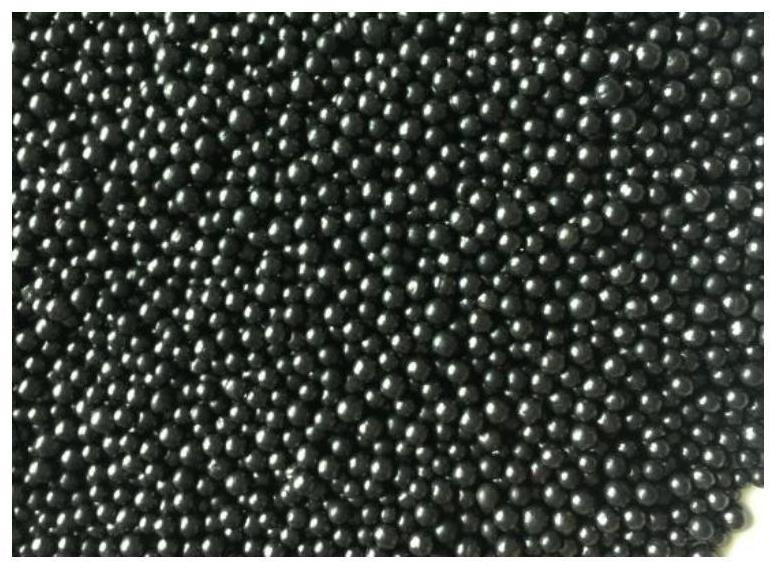

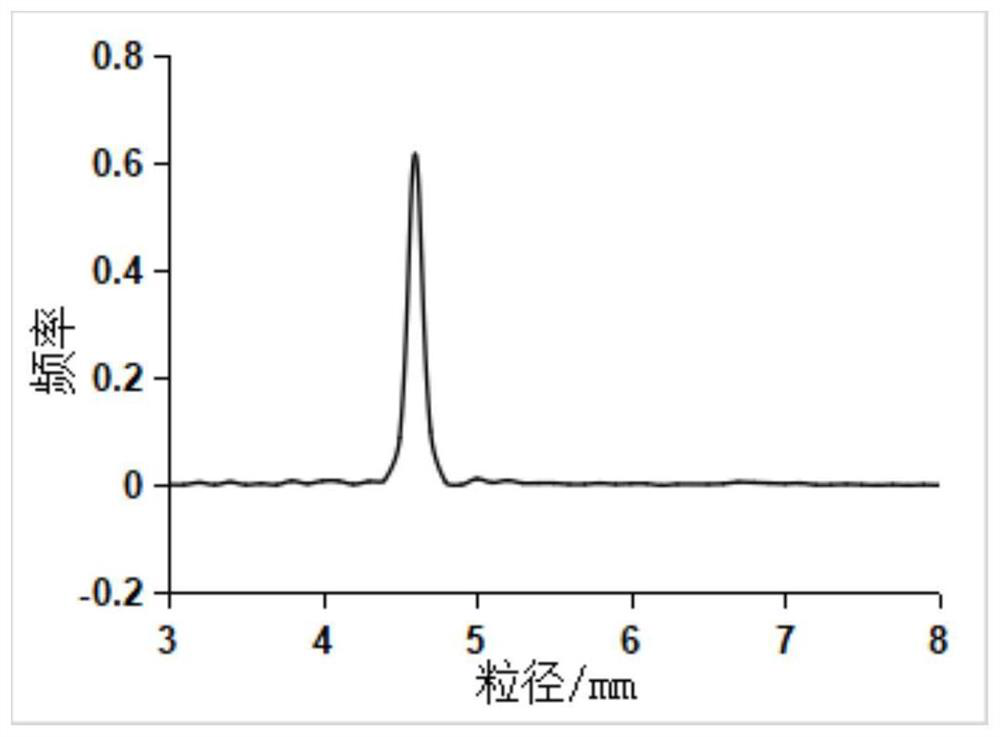

[0052] The characterization of embodiment 2 spherical mesoporous carbon

[0053] In order to confirm that the spherical mesoporous carbon prepared by the method for preparing spherical mesoporous carbon in Example 1 of the present invention has excellent characteristics, the spherical mesoporous carbon prepared in Example 1 was characterized.

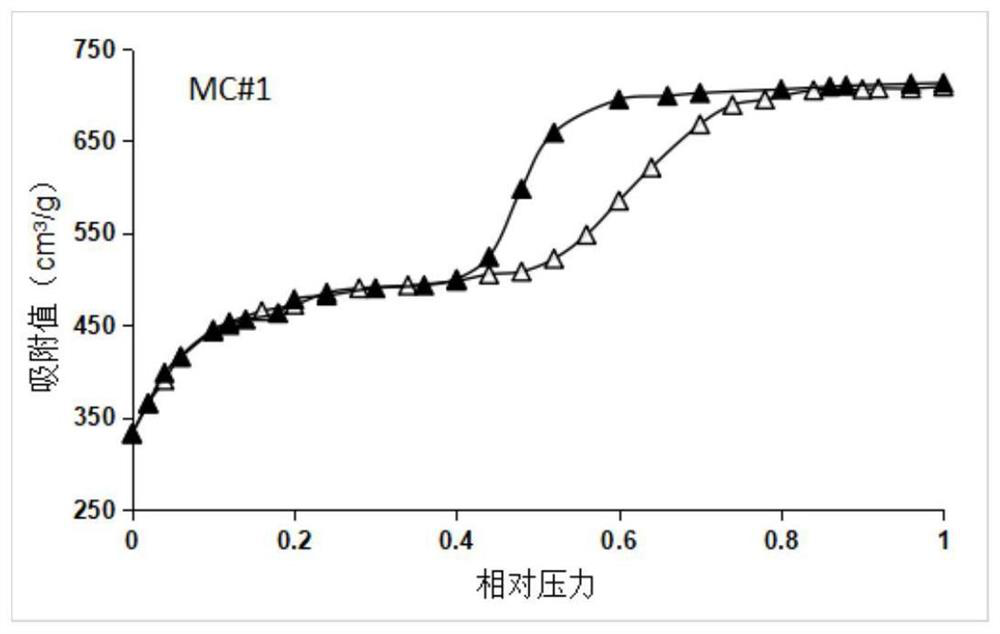

[0054] The spherical mesoporous carbon pore structure was determined by using a 3H-2000Ps2 specific surface and pore size analyzer produced by Beijing Best Instrument Technology Co., Ltd., using nitrogen as the adsorption medium, at 77K and relative pressure (P / P 0 ) is 10 -3 The nitrogen adsorption measurement was carried out under the condition of ~1.0. The spherical mesoporous carbon was degassed at 300 °C for 12 h before testing.

[0055] The specific surface area is calculated using the BET model; the specific surface area of the micropores is calculated using the t-plot equation; the pore volume is calculated from the adsorpti...

Embodiment 3

[0061] Example 3 The effect of spherical mesoporous carbon adsorption formaldehyde

[0062] The adsorption experiment was carried out on the Type 002 Intelligent Gravimetric Analyzer (IGA) of British Hiden Company. The device is mainly composed of a test system, a molecular pump and an analysis system.

[0063] Before the adsorption experiment started, 50-80 mg of spherical mesoporous carbon was degassed under vacuum at 120°C. During the test, the vapor of VOCs gradually enters the test system, increasing the system pressure until the saturated vapor pressure of the VOC.

[0064] In this example, the inventors used the spherical mesoporous carbon prepared in Example 1 of the present invention to adsorb formaldehyde at room temperature to obtain the adsorption capacity for formaldehyde.

[0065] The result is as Figure 4 As shown, the adsorption curve of the spherical mesoporous carbon prepared in Example 1 to formaldehyde basically conforms to Type I adsorption curve, that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption performance | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com