Aluminum oxide-hydroxyapatite-chitosan composite adsorption material, preparation method and application thereof

A composite adsorption material, hydroxyapatite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of complex preparation process of adsorption materials, high processing cost, environmental pollution, etc., to achieve Good economic benefits, reduce environmental pollution, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

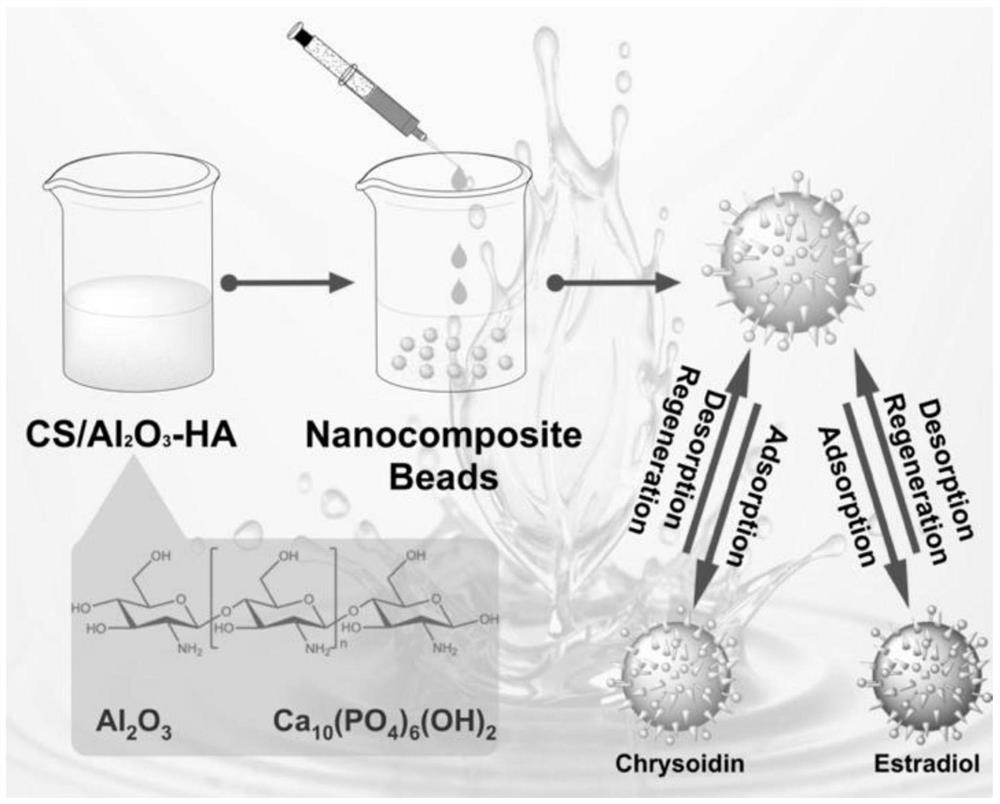

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of aluminum oxide-hydroxyapatite-chitosan composite adsorption material, comprising the following steps:

[0036] Step 1, 6g chitosan is dissolved in 60mL, volume fraction is in the acetic acid solution of 2%, makes chitosan solution;

[0037] Step 2. Add 200mL, 1mol / L alumina solution to 200mL, 1mol / L, calcium chloride / phosphoric acid solution with a mass fraction of 40%, stir continuously for 2.5h, and then add 100mL of 30% Ammonia, after continuing to stir at room temperature for 1.5h, was washed and dried to obtain alumina-hydroxyapatite material;

[0038] Calcium chloride / phosphoric acid solution is prepared according to the following steps: calcium chloride and phosphoric acid with a molar ratio of 5:3 are jointly added to deionized water;

[0039] Step 3. Add 60 mg of the alumina-hydroxyapatite material prepared in step 2 to 1 L of the chitosan solution prepared in step 1, stir for 2.5 hours to obtain a mixed solution, and add the mixed solu...

Embodiment 2

[0041] A preparation method of aluminum oxide-hydroxyapatite-chitosan composite adsorption material, comprising the following steps:

[0042] Step 1, 7g chitosan is dissolved in 60mL, volume fraction is in the acetic acid solution of 2%, makes chitosan solution;

[0043] Step 2. Add 200mL, 1mol / L alumina solution to 200mL, 1mol / L, calcium chloride / phosphoric acid solution with a mass fraction of 40%, stir continuously for 2.5h, and then add 100mL of 30% Ammonia, after continuing to stir at room temperature for 1.5h, was washed and dried to obtain alumina-hydroxyapatite material;

[0044] Calcium chloride / phosphoric acid solution is prepared according to the following steps: calcium chloride and phosphoric acid with a molar ratio of 5:3 are jointly added to deionized water;

[0045] Step 3. Add 120 mg of the alumina-hydroxyapatite material prepared in step 2 to 1 L of the chitosan solution prepared in step 1, stir for 2.5 hours to obtain a mixed solution, and add the mixed solut...

Embodiment 3

[0047] A preparation method of aluminum oxide-hydroxyapatite-chitosan composite adsorption material, comprising the following steps:

[0048] Step 1, 5g chitosan is dissolved in 70mL, volume fraction is in the acetic acid solution of 2%, makes chitosan solution;

[0049] Step 2. Add 60 mL of 0.5 mol / L alumina solution to 180 mL of 1 mol / L calcium chloride / phosphoric acid solution with a mass fraction of 40%, stir continuously for 2 hours, and then add 84 mL of ammonia water with a volume fraction of 30% , continue to stir at room temperature for 1 hour, and then wash and dry to obtain alumina-hydroxyapatite material;

[0050] Calcium chloride / phosphoric acid solution is prepared according to the following steps: calcium chloride and phosphoric acid with a molar ratio of 5:3 are jointly added to deionized water;

[0051] Step 3. Add 30 mg of the alumina-hydroxyapatite material prepared in step 2 to 1 L of the chitosan solution prepared in step 1, stir for 3 hours to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com