A compound flocculation sedimentation tank suitable for low turbidity water quality

A sedimentation tank and water quality technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation tank, etc., can solve the problems of poor sedimentation effect, affecting effluent quality, uneven water distribution, etc., to improve the removal effect, improve the turbidity removal rate and The removal rate of organic matter and the effect of improving turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

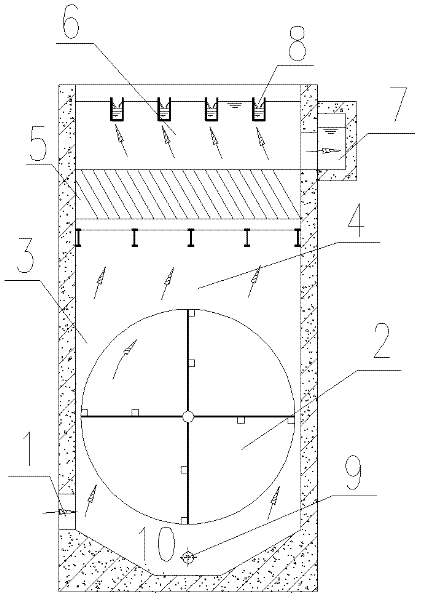

[0045] Figure 1-Figure 5 Given is a basic type of flocculation sedimentation tank, the water flow direction is as follows figure 2As shown by the arrow, the water enters the lower part of the flocculation zone 3 from the water inlet hole 1 after being fully mixed with the drug, and flows from bottom to top. The purpose of the setting is to make the water flow into the inclined pipe 5 evenly. During the flow of the inclined pipe 5, the water impurities sink on the inclined pipe 5, and the water flows upward into the clear water area 6, and then flows into the water collection channel 7 from the sump 8. The water outlet pipe 13 enters the next processing unit.

Embodiment 2

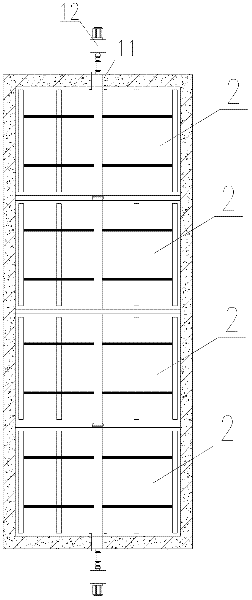

[0047] Figure 6 Provided is an improved compound flocculation sedimentation tank. It is characterized by setting multi-stage flocculation in the pool, Figure 6 The middle is 3-stage flocculation, after the 1st and 2nd-stage flocculation, and before the 3rd-stage flocculation, an intermediate zone 16 is set. The purpose of setting the intermediate zone is that, due to the fast stirring speed of the agitator 2 in the first two stages of flocculation process, the formation of flocs is less, and the satisfactory turbidity removal effect may still not be achieved after sedimentation in the inclined tube 5, so the water in the first, After the second-stage flocculation, it is collected by the water collection channel 7 and then re-enters the third-stage flocculation through the middle area. Figure 6 The middle arrow shows the direction of water flow.

[0048] Whether the intermediate zone 16 is set or not, whether single-stage flocculation or multi-stage flocculation is used, ...

Embodiment 3

[0050] In the flocculation zone 3, flocs with a small volume density will be generated during the slow stirring process of the agitator 2, and these flocs will enter the sedimentation zone with the water flow upwards and deposit in the inclined tube 5. The shape of the flocs slides back into the flocculation zone 3; these larger flocs rotate with the agitator 2, and in this process absorb the newly formed smaller flocs; the bulk density of the flocs will further increase during the adsorption process. Large, finally sink down to the mud discharge area 10, and be discharged from the perforated mud discharge pipe 9. This process requires the stirring speed of the agitator to be slow enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com