Workpiece processing system

A technology for workpieces and processing chambers, which is applied in washing and drying, surface treatment of workpieces, and cleaning fields. It can solve problems such as insufficient particle specifications, achieve stable wafer processing effects, reduce particle pollution, and improve production pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

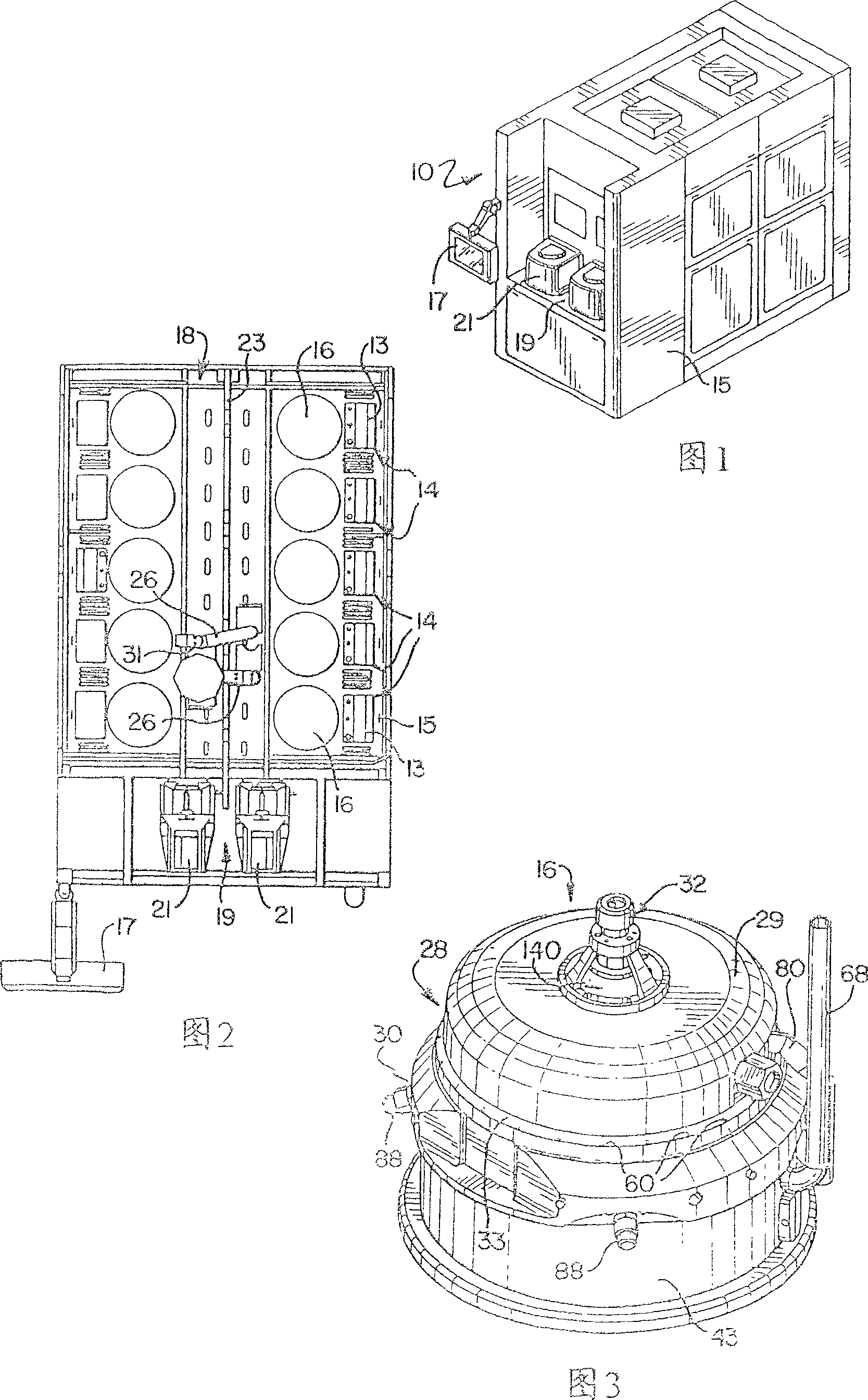

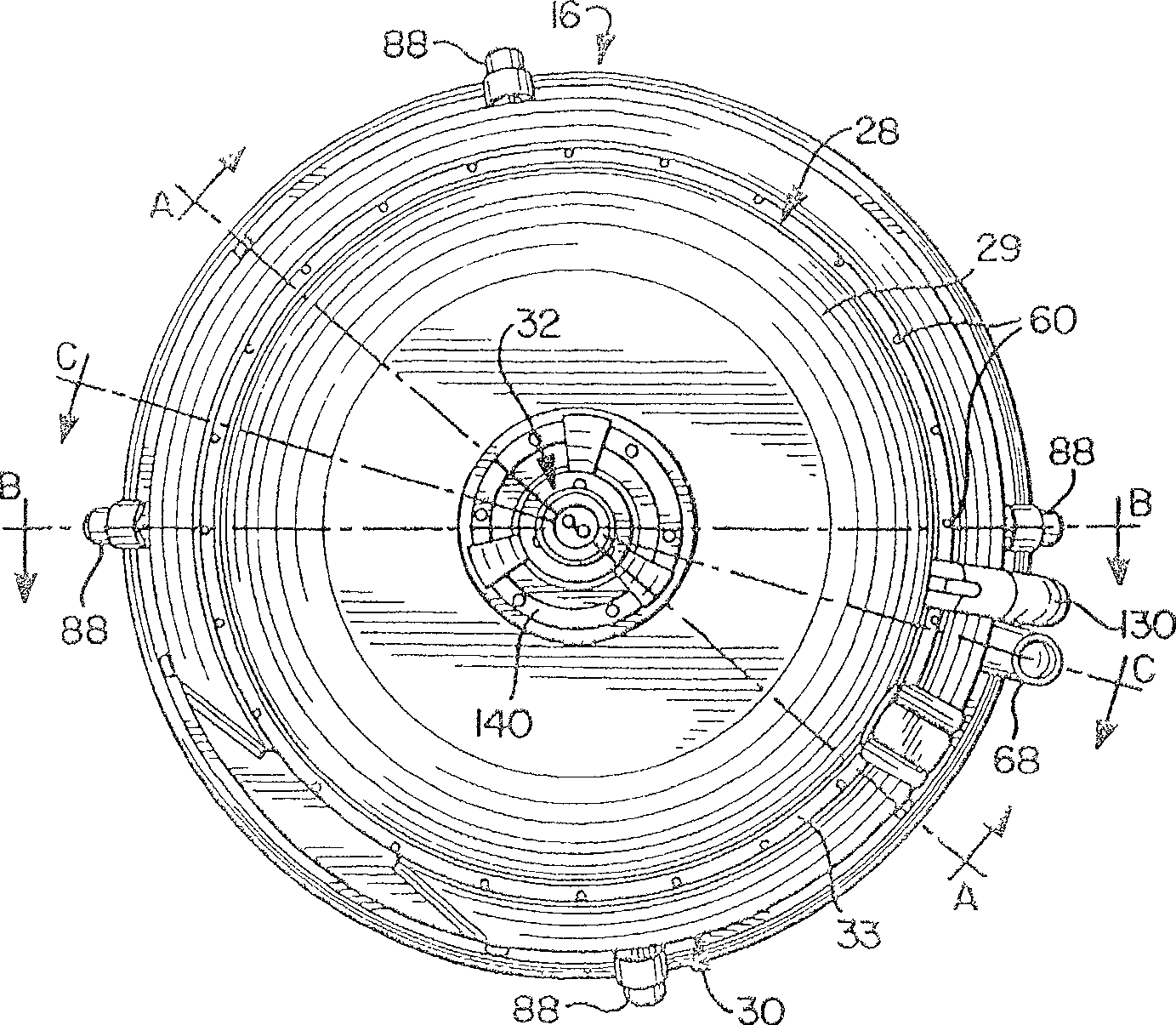

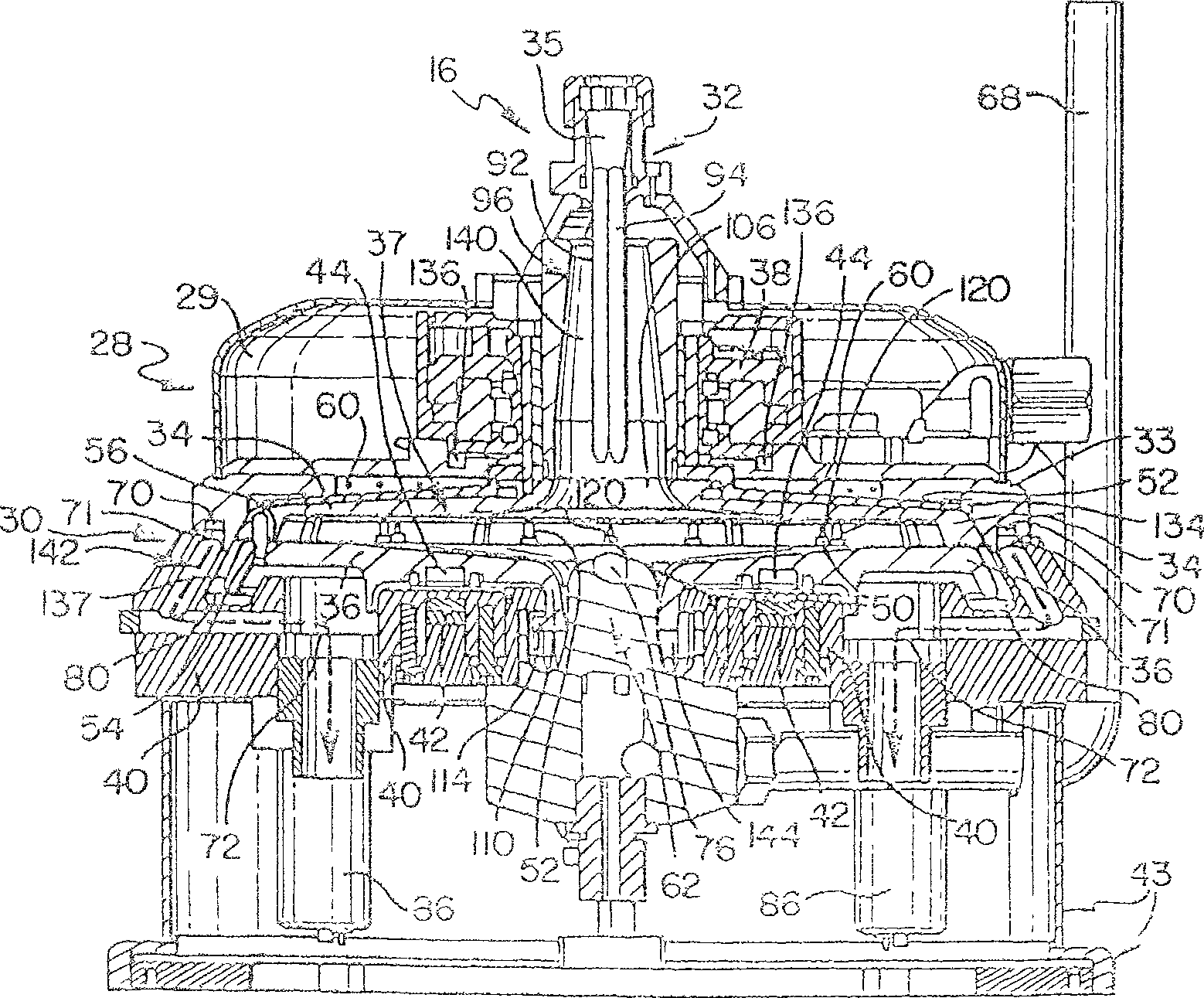

[0075] Description with reference to Figures 1 to 3

[0076] As shown in FIGS. 1-3 , processing system 10 has housing 15 , controller / display 17 , and input / output station 19 and a plurality of processing stations 14 . Workpieces 24 are removed from carriers 21 at input / output station 19 and processed within system 10 .

[0077] The processing system 10 includes a support structure for a plurality of processing stations 14 within an enclosure 15 . At least one handling station 14 includes a workpiece handling machine 16 and an actuator 13 for opening and closing the handling machine 16 . The processor 16 of the present invention is designed for use in processing systems 10, such as those filed on June 6, 2003, Application Nos. 691,688, and the processing system disclosed in co-pending US Patent Application No. 10 / 690,864, filed October 21, 2003. These US patent applications are hereby incorporated by reference. System 10 may include only a plurality of processors 16, or ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com