Biological chips sample application platform

A biochip and platform technology, applied in the field of microarray biochip preparation, can solve the problems of inability to meet rapid and large-scale production, poor accuracy and work stability, and single substrate for spotting, and achieve improved spotting efficiency and high accuracy. , avoid the effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

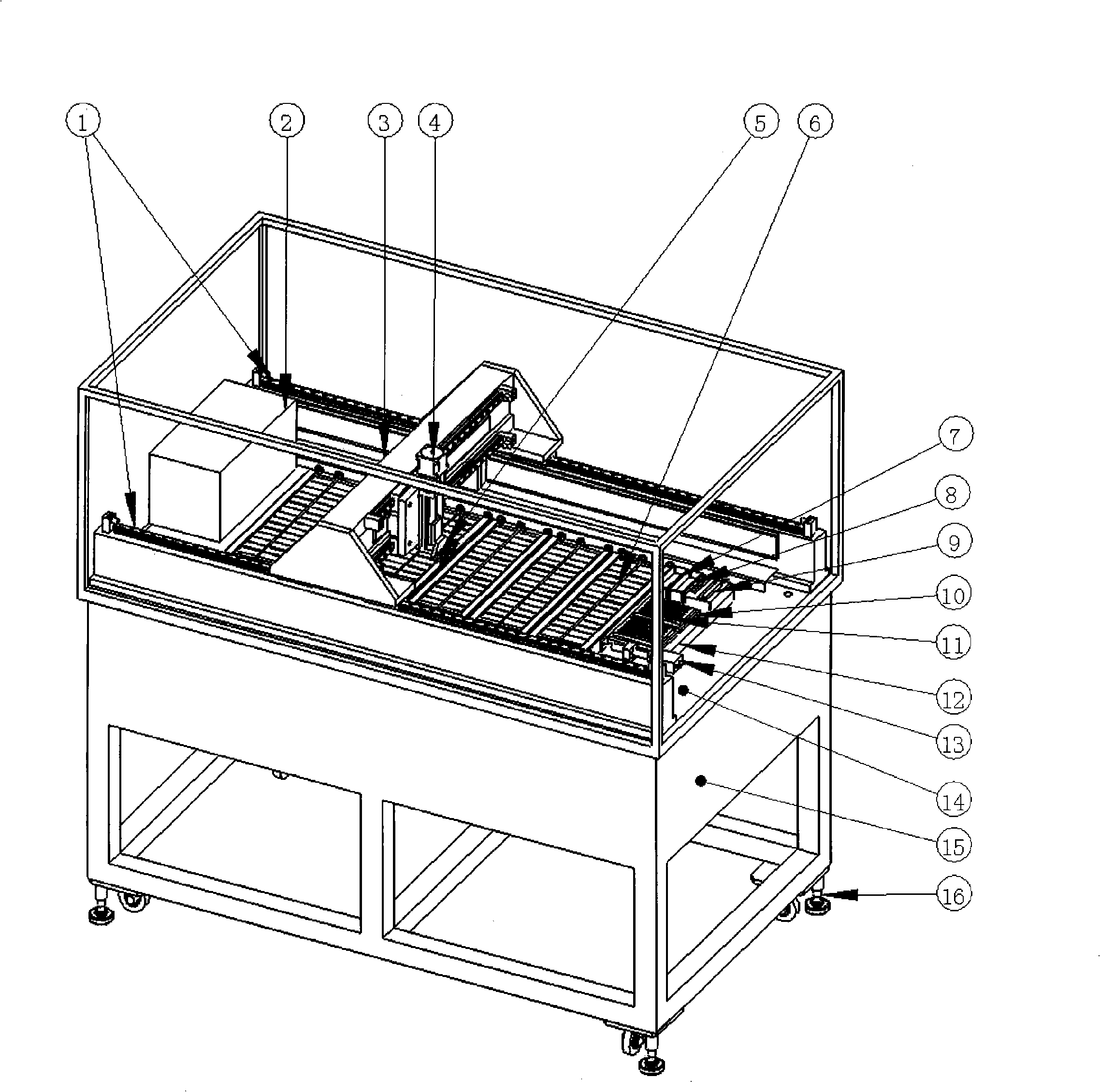

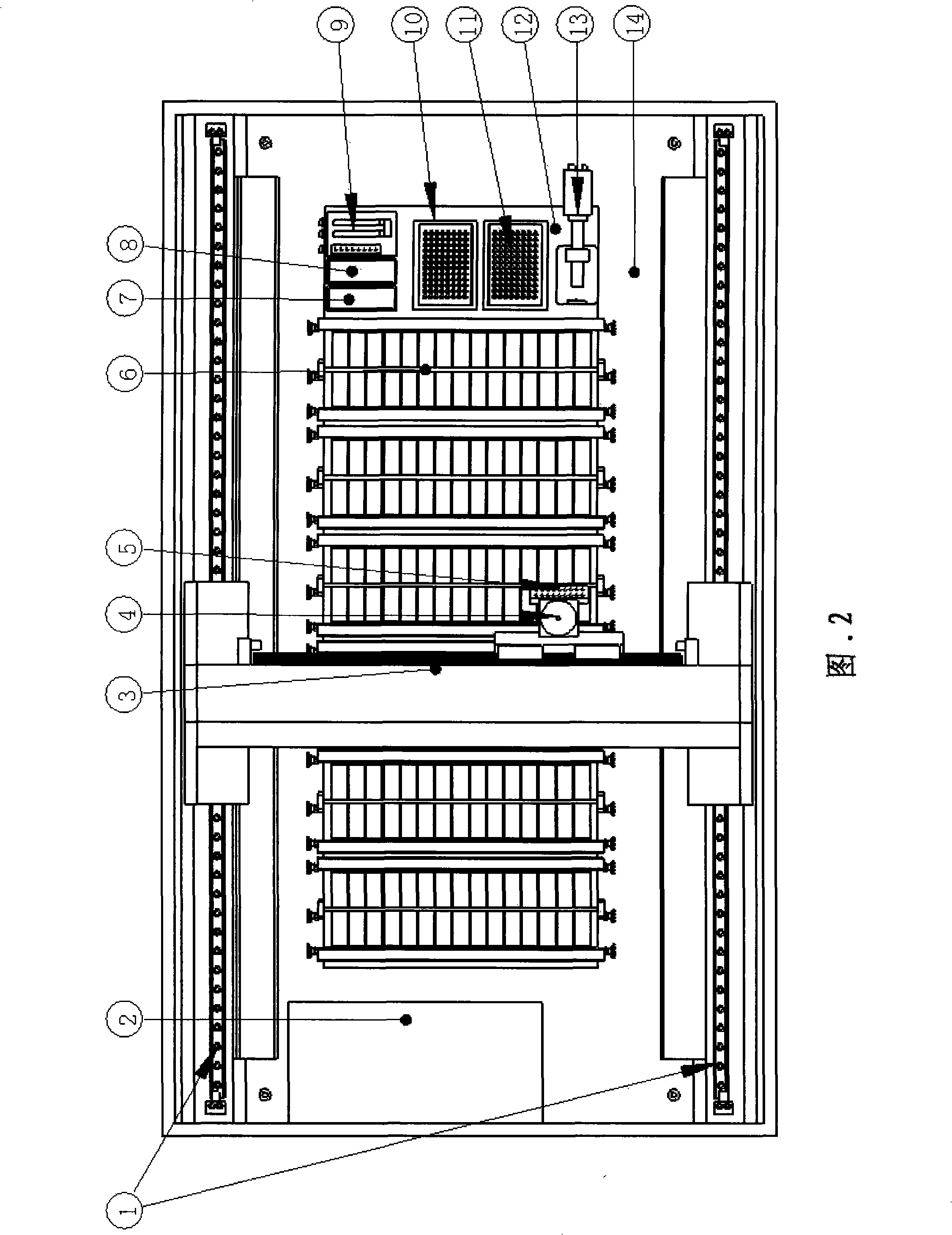

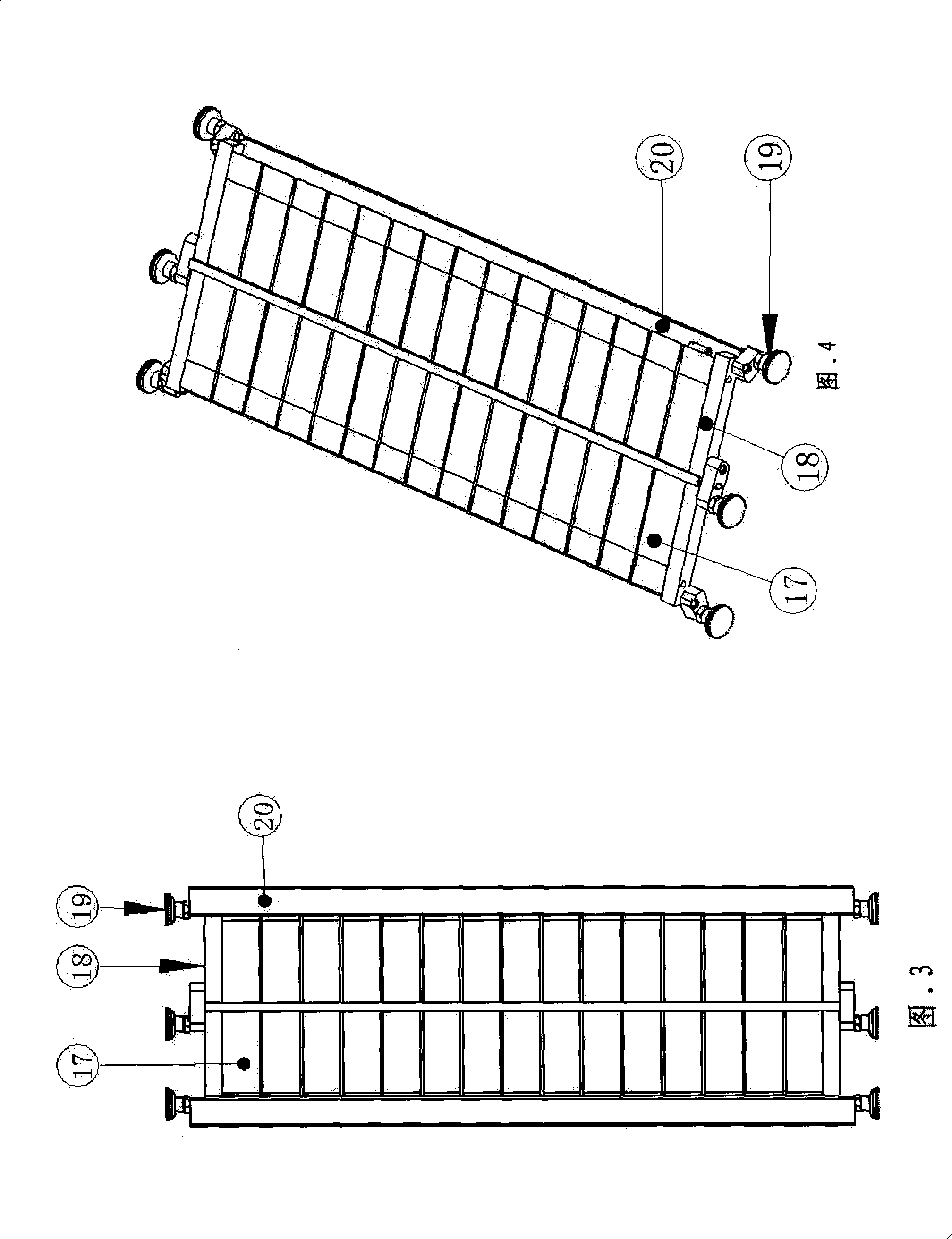

[0032] As shown in Fig. 1 and Fig. 2, a kind of biochip sampling platform of the present invention comprises base (14), is installed on the working platform (12) on the base (14), with precision linear motor (1) and (3) and a three-dimensional distributing manipulator combined with a precision electronically controlled translation stage (4), and has a sampling head (5) with 1 to 48 sampling needles. The base (14) can be placed directly on the desktop through the adjustable supporting feet, or placed on the ground through the bracket and the adjustable pulley foot group (16). The working platform (12) is provided with a chip fixing platform (6), buffer tanks (7) and (8), a sample box platform (10), a sampling needle cleaning and drying device (9), and a review and photographing device (13).

[0033] Wherein, the three-dimensional distribution manipulator is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com