Novel internal cooling grinding abrasive wheel

A grinding wheel, a new type of technology, applied in the field of grinding processing, can solve the problems of increasing the overall production cost of the grinding wheel, high processing cost, and complex inner flow channel processing technology, and achieve low production cost, increased coolant flow, and low technical threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

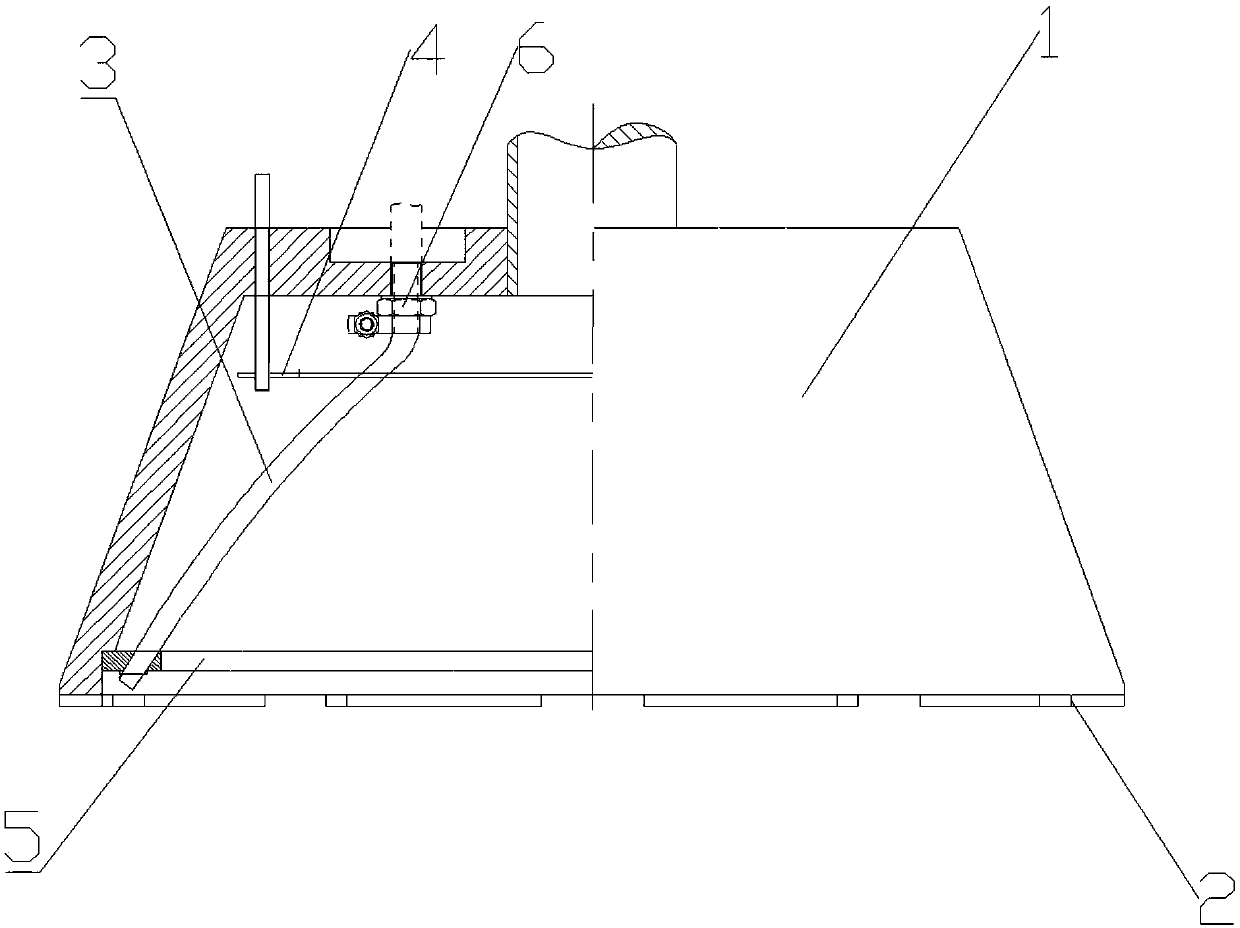

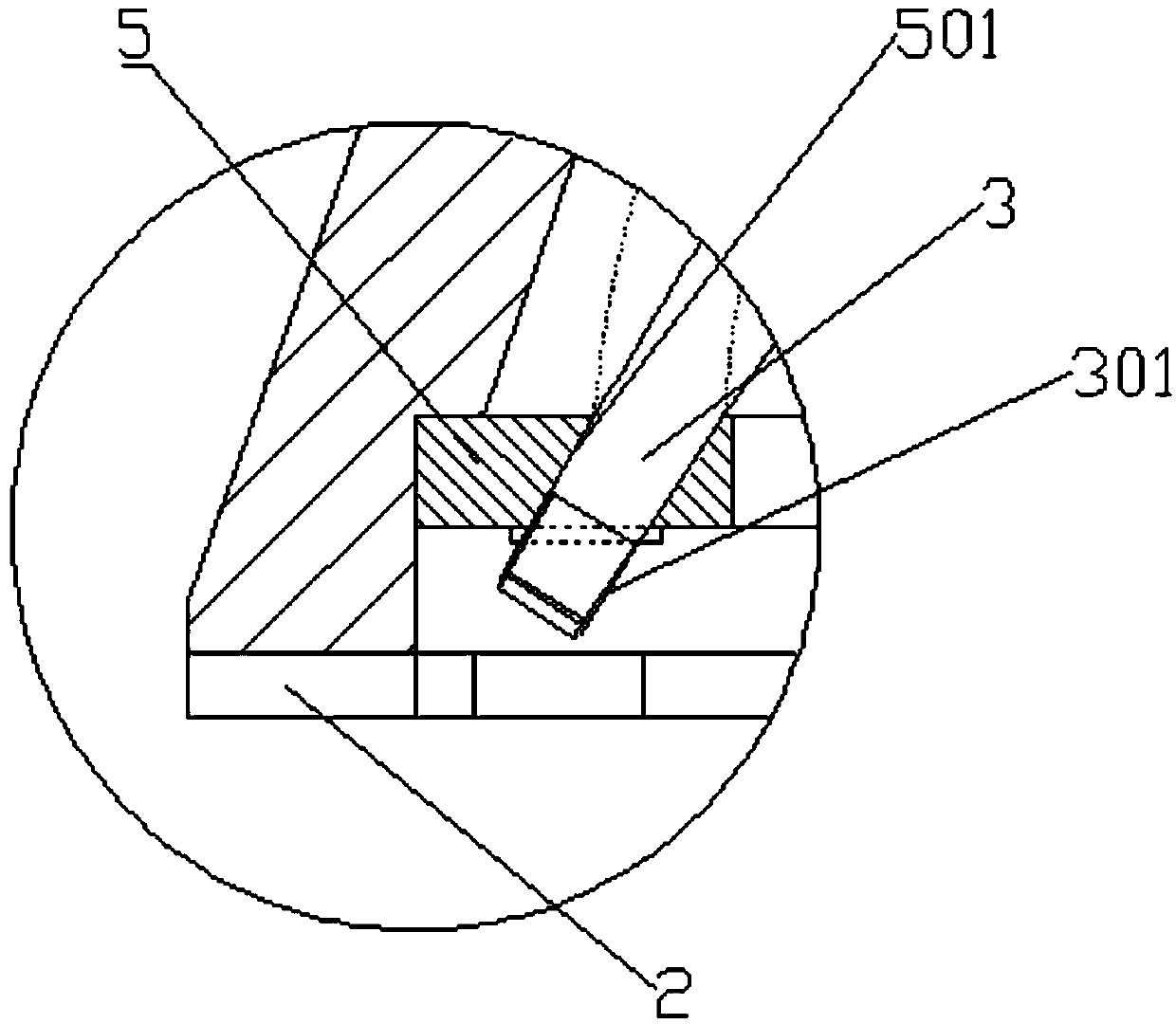

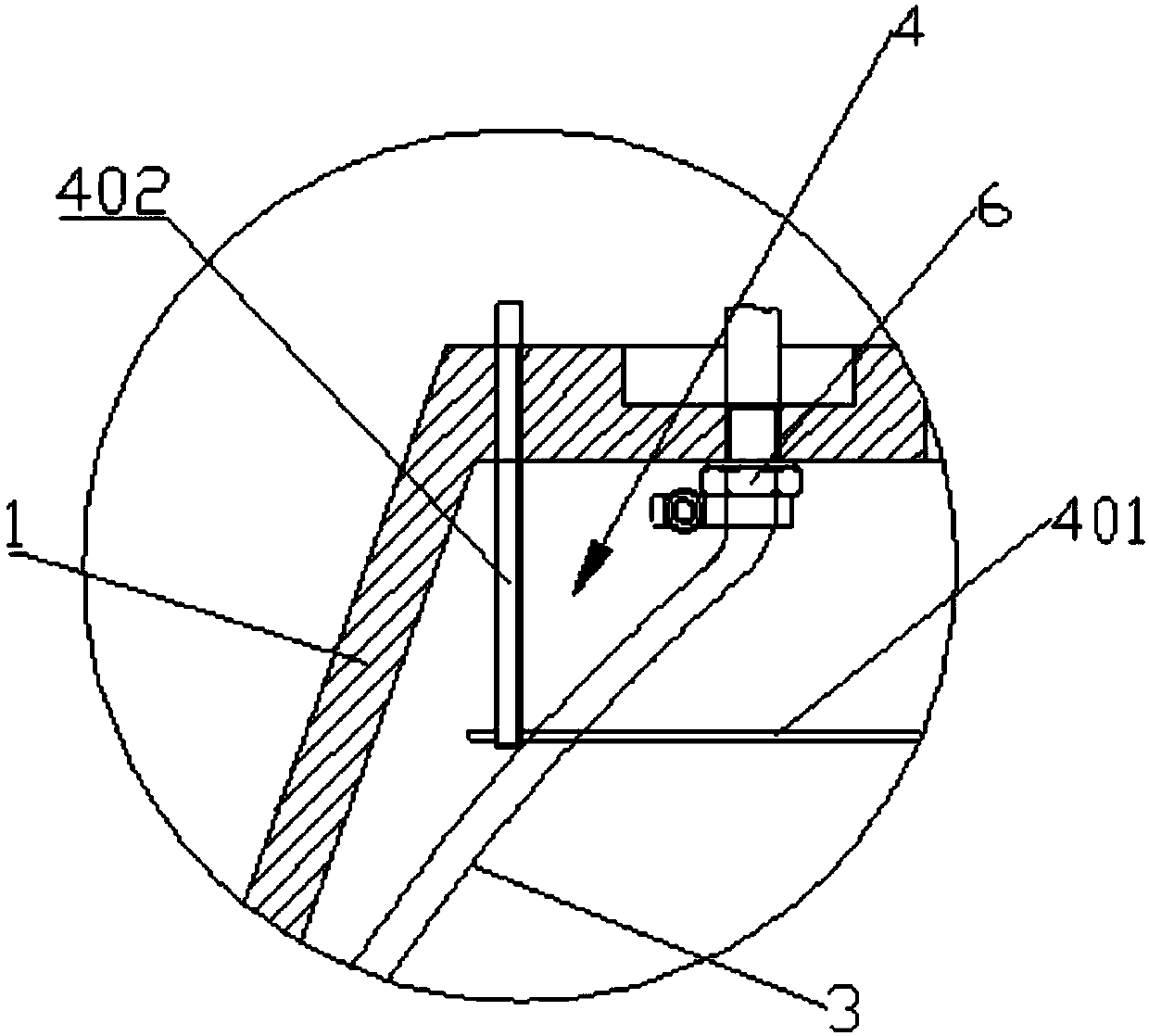

[0079] A new internally cooled grinding wheel, the grinding wheel includes a grinding wheel body 1 and a grinding part 2; the grinding wheel body 1 opens downward; the upper end of the grinding wheel body 1 is connected to the handle of a machine tool; the grinding part 2 is arranged at the bottom of the grinding wheel body The grinding wheel also includes a coolant guide pipe 3; the coolant guide pipe 3 is arranged in the inner cavity of the grinding wheel main body 1; the water inlet end of the coolant guide pipe 3 runs through the top of the inner cavity of the grinding wheel main body 1, and the coolant supply part Communication; the water outlet end of the coolant guide pipe 3 is fixedly arranged on the inner edge of the lower end of the grinding wheel main body 1 .

Embodiment 2

[0081] Example 1 is repeated, except that the coolant guide pipe 3 is made of elastic material.

Embodiment 3

[0083] Repeat Example 2, except that the coolant guide pipe 3 is a rubber hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com