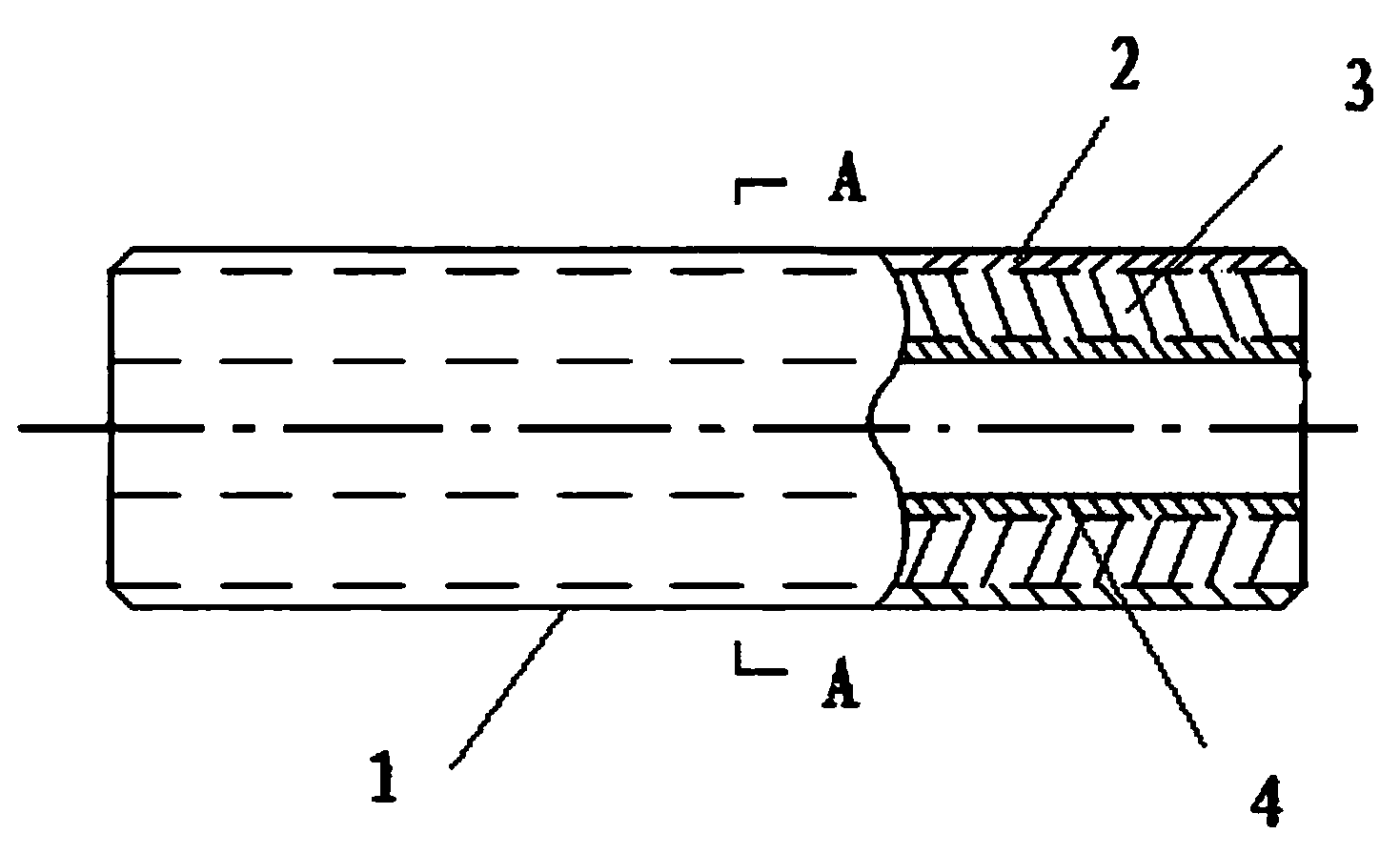

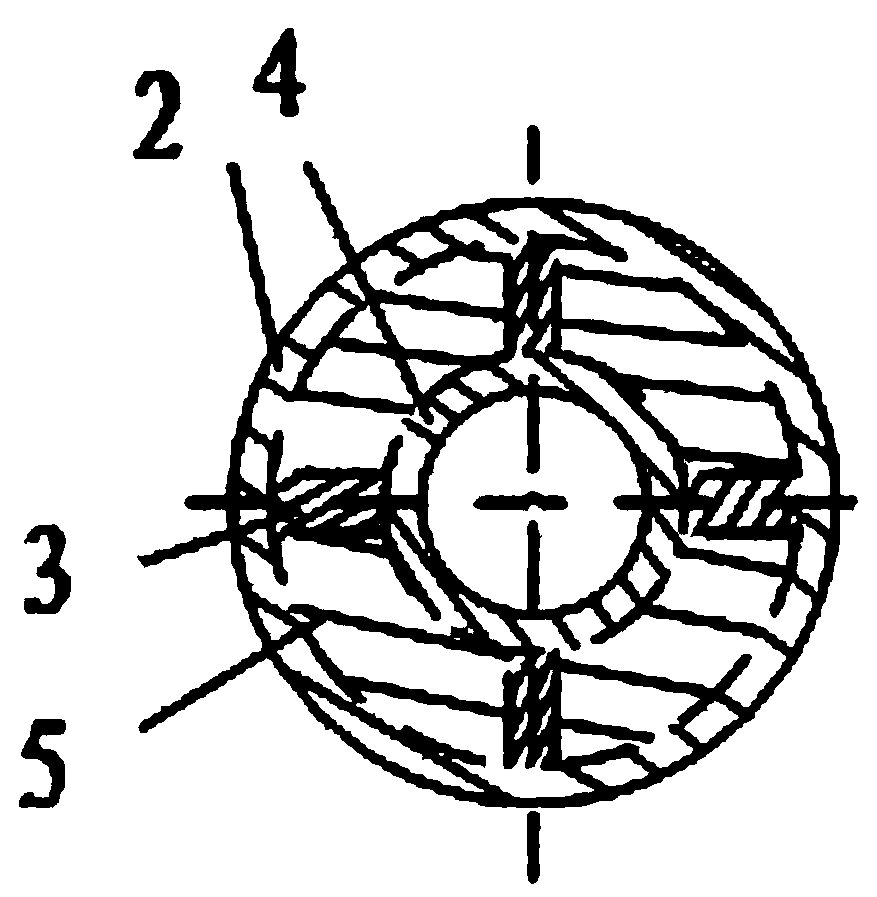

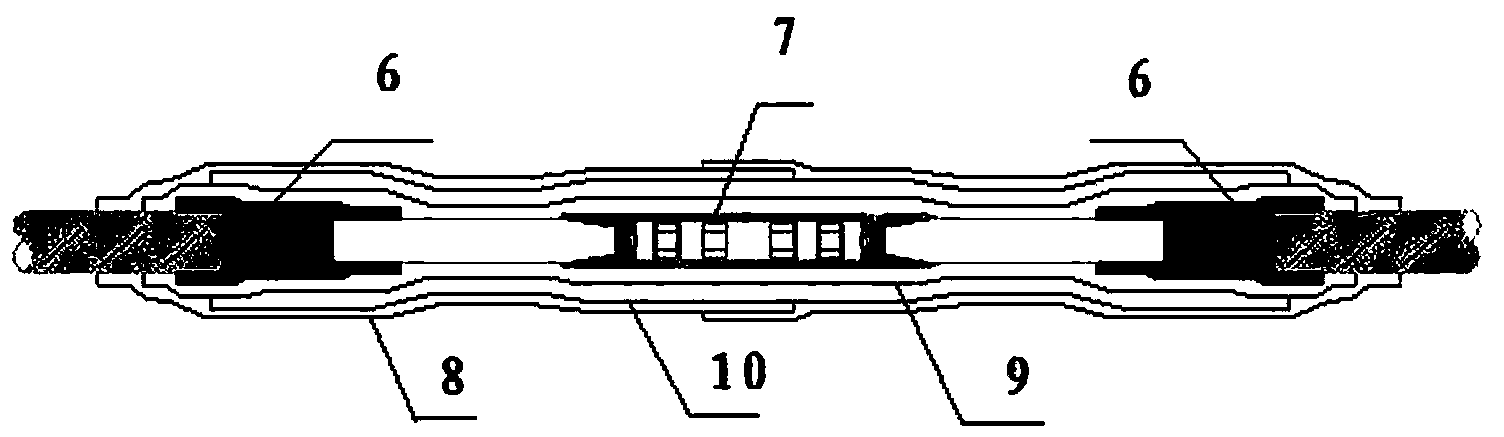

Middle joint connection tube of phase-change temperature-control type high-voltage cable

A technology of high-voltage cables and intermediate joints, applied in the direction of cable joints, etc., can solve the problems of overheating of joints, accelerated thermal aging of cable joints, and different joint production, so as to reduce operating temperature, prolong service life, and avoid overheating failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0023] Phase change materials (PCM for short) are a special class of functional materials, which can undergo phase transitions (mostly solid-liquid phase transitions or gas-liquid phase transitions) under isothermal or near isothermal conditions, accompanied by large energy ( Commonly referred to as latent heat of phase change) absorption or release, this feature is the reason and basis for this type of material to have a wide range of applications. The composite phase change material overcomes many problems in the use of traditional phase change materials, and has many excellent properties: (1) The stored thermal energy is large and the temperature can be adjusted. (2) It can be directly formed and processed, and the requirements for the container are not high or even directly used as a skeleton material without the need for container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com