Manufacturing method of ink-free printing package

A production method and ink printing technology, which are applied in the printing, printing, and printing process of producing special varieties of printed matter, can solve problems such as air pollution, and achieve the effect of reducing process links, unique color performance, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

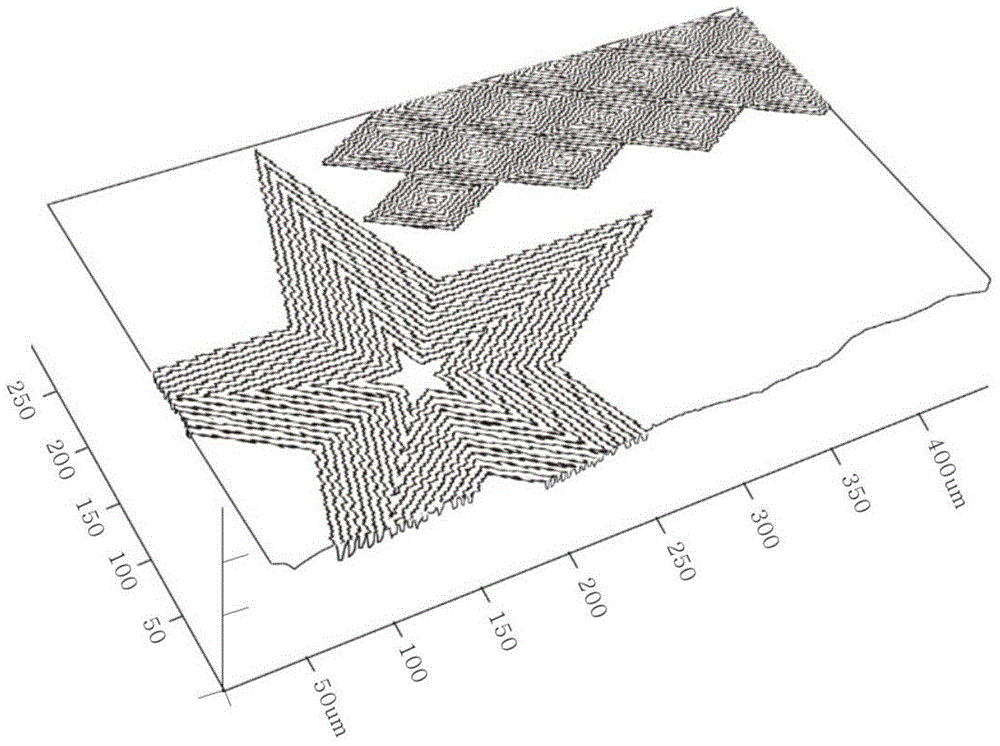

[0047] Inkless printing self-adhesive label production: using ultra-precision CNC method, laser direct writing method, holographic exposure method, semiconductor photolithography method, plasma texturing method to obtain a microstructure relief metal mold, coated on the surface of PET film with high thermoplasticity Molecular resin layer with a thickness of 2μm to 4μm; vapor-deposited metal reflective layer with a thickness of 40nm to 100nm; the microstructure mold is transferred and formed on the PET coating surface by heating and nano-imprinting; the unnecessary metal reflective layer is etched by mask method Remove, reapply stickers, die-cut finished products, such as Image 6 shown.

Embodiment 2

[0049] Production of transfer-type inkless printing and packaging: first design and manufacture microstructure relief molds, and then coat easy-peelable thermoplastic coatings on the PET base film. The structure is embossed on the coating, and the metal film layer is partially evaporated; the microstructure surface obtained by embossing is bonded to the packaging printing substrate, and after drying, the PET base film is peeled off to complete the transfer of the microstructure, inkless packaging printing done see Figure 7 , PET can be reused by recycling the above process.

Embodiment 3

[0051] Composite inkless printing and packaging production: design and manufacture to obtain a microstructure relief mold, use corona, plasma, and coating methods on the surface of the PET film to obtain the surface dyne value treatment, and use UV glue on the microstructure mold and the PET treatment surface Composite, after UV curing, the PET and the microstructure mold are separated, and the microstructure displayed by the graphic is copied on the PET with the cured UV glue, and then the metal layer or transparent high-refractive index layer is evaporated to obtain the brightening of the graphic. Paste the vapor-deposited side of the obtained graphic film on the printing and packaging substrate, such as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com