Preparation method of functionalized photocatalyst fibers

A functional and photocatalyst technology, applied in the field of fiber manufacturing, can solve the problems of photocatalytic purification efficiency, photocatalytic performance is difficult to be widely applied, etc., and achieve the effect of industrialization promotion, powerful function and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

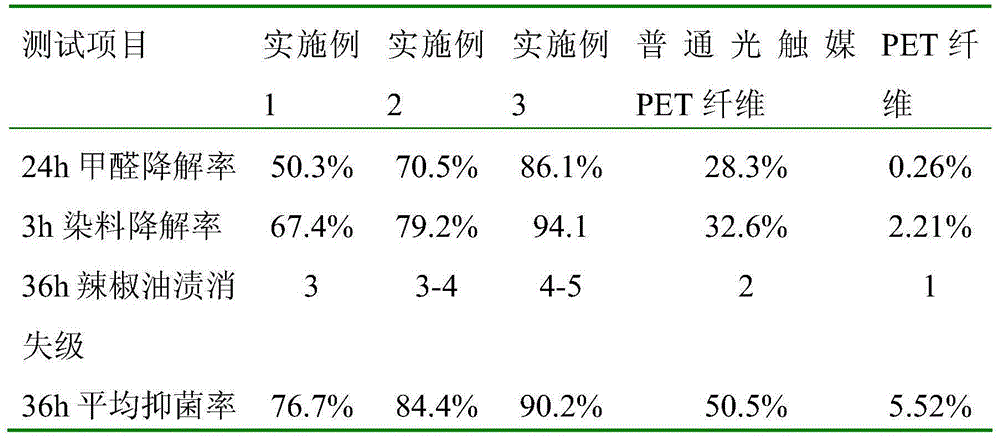

Examples

preparation example Construction

[0013] The preparation method (abbreviation method) of the functionalized photocatalyst fiber of the present invention's design, this method adopts following technology:

[0014] (1) Preparation of functionalized nano-TiO2 powder

[0015] Add 5.0g of ferric chloride and 3.0g of graphene oxide into 1000ml of nano-TiO2 aqueous sol, and stir at high speed for 2h at room temperature, then cool, filter and bake at high temperature to obtain surface-coated iron and graphene. Functionalized nano-TiO2 powder; the specification of the graphene oxide is that the average thickness is 1.5nm, and the average bulk density is 0.68g / m 3 ; The hydrosol requires a wide spectral response type, with an average particle size of 2-3nm;

[0016] (2) Preparation of functionalized PET masterbatch containing nano-TiO2

[0017] Put functionalized nano-TiO2 powder with a mass fraction of 15‐45%, 1.0‐2.0% polyethylene dispersant and 53‐84% PET slices into a high-speed mixer and mix evenly, and then use ...

Embodiment 1

[0026] A functionalized photocatalyst fiber is prepared.

[0027] (1) Preparation of functionalized nano-TiO2 powder

[0028] 5.0g ferric chloride and 3.0g graphene oxide (average thickness: 1.5nm, average bulk density: 0.68g / m 3 ) was added to 1000ml of nano TiO2 hydrosol (average mass content of nano TiO2 particles with an average particle size of 2‐3nm: 2.50%), and stirred at a high speed for 2h at room temperature, then cooled, filtered and baked at 120°C Finally, the functionalized nano-TiO2 powder coated with iron and graphene on the surface is obtained.

[0029] (2) Preparation of functionalized PET masterbatch:

[0030]Put the functionalized nano-TiO2 powder, 1.0% polyethylene dispersant (relative molecular mass 2000)) of mass fraction 15% and 84% PET chip into high-speed mixer and mix uniformly, then use extruder to carry out at 180 ℃ Melt mixing and extrusion, cooling in a water bath, pelletizing with a pelletizer, and finally vacuum drying to obtain functionalize...

Embodiment 2

[0035] A functionalized photocatalyst fiber is prepared.

[0036] (1) Preparation of functionalized nano-TiO2 powder

[0037] Step is identical with embodiment 1.

[0038] (2) Preparation of functionalized PET masterbatch

[0039] The functionalized nano-TiO2 powder of mass fraction 30%, the polyethylene dispersant of 1.5% (relative molecular weight 2000) and the PET chip of 68.5% are put into high-speed mixer and mix evenly, use extruder to carry out melting at 200 ℃ then Mix and extrude, cool in a water bath, pelletize with a pelletizer, and finally dry in a vacuum to obtain functionalized PET masterbatches.

[0040] (3) Spinning of skin-core functionalized photocatalyst fiber

[0041] First, the mass fraction of 35% containing nano-TiO 2 The functionalized PET masterbatch and 65% PET chips were vacuum-dried for 1 hour, and then mixed and melt-spun at 280°C by a twin-screw composite spinning machine with a sheath-core composite spinning assembly, and then passed through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com