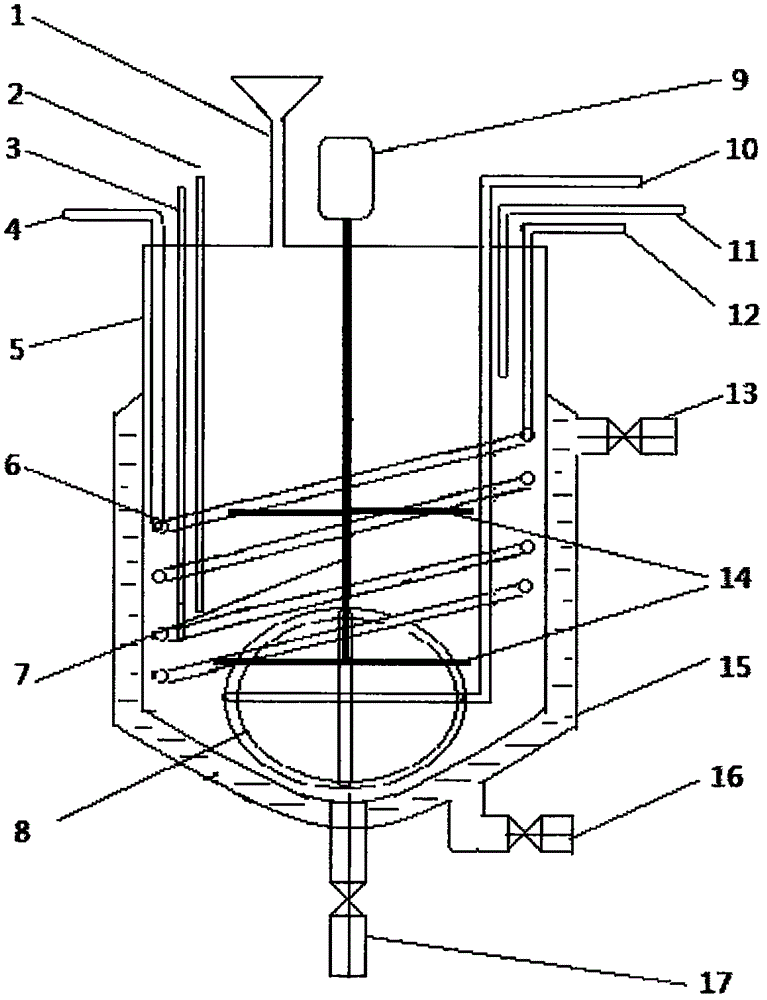

Carbonization and activation integration device and method for producing nano calcium carbonate

A technology of nano-calcium carbonate and carbonization reaction, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of lower production efficiency, energy consumption, product return to alkali, etc., to ensure consistency and integrity, improve distribution Effect, the effect of avoiding carbonization dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

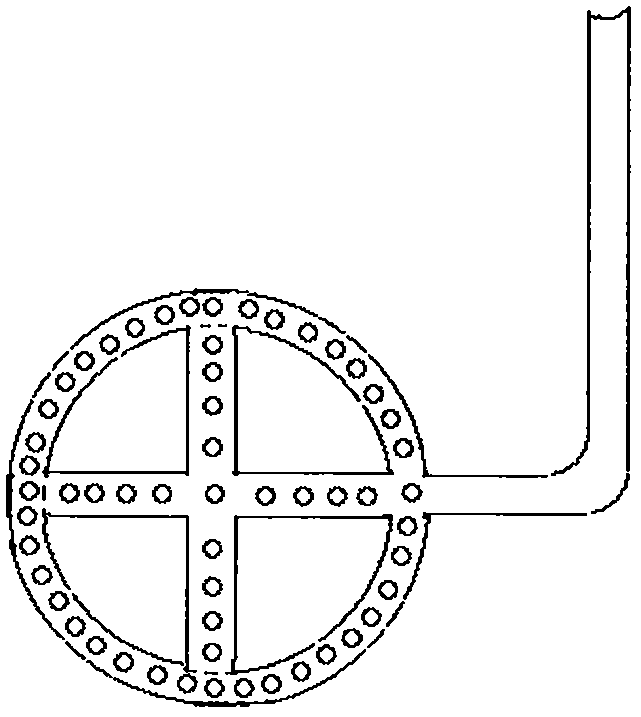

Method used

Image

Examples

Embodiment 1

[0023] At room temperature, the calcium hydroxide slurry with a mass percentage concentration of 8% after deslagging and refining treatment is pumped into the carbonization and activation integrated device with a sizing pump, and the stirring is started at a stirring speed of 150 revolutions per minute. Put in cooling water to cool, control the carbonization reaction temperature not to exceed 40°C, pass carbon dioxide-air mixed gas to carry out carbonization reaction, measure the temperature by thermocouple, and measure the pH by acidity meter to characterize the progress of carbonization reaction. As the carbonization reaction progresses, adjust The volume percent concentration of the carbon dioxide injected is gradually reduced from the initial 80% to 30%. When the pH value of the carbonized liquid reaches 6, stop feeding the carbon dioxide-air mixture, stop the refrigeration, end the carbonization reaction, and then start the heat conduction oil heating. Stir rapidly, the st...

Embodiment 2

[0025] At normal temperature, the calcium hydroxide slurry with a mass percentage concentration of 13% after slag removal and refining treatment is pumped into the carbonization and activation integrated device with a sizing pump, and 0.5% zinc sulfate equivalent to the dry weight of calcium hydroxide is added. Turn on the stirring, the stirring speed is 250 revolutions per minute, pass cooling water into the cooling coil, control the carbonization reaction temperature not to exceed 50°C, pass carbon dioxide-air mixed gas for carbonization reaction, measure temperature by thermocouple, pass acidity As the carbonization reaction progresses, adjust the volume percent concentration of carbon dioxide introduced from the initial 100% to 50%, and when the pH value of the carbonization solution reaches 7, stop feeding carbon dioxide-air Mix gas, stop refrigeration, end carbonization reaction, start heat conduction oil heating again, stir rapidly, the stirring speed is 400 rpm, when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com